Shenzhen Hansome Technology Co., Ltd. |

|

Verified Suppliers

|

|

Malfunction Alarm And Emergency Braking System Full Inspection Window SMT Nozzle Cleaner

Technical Details

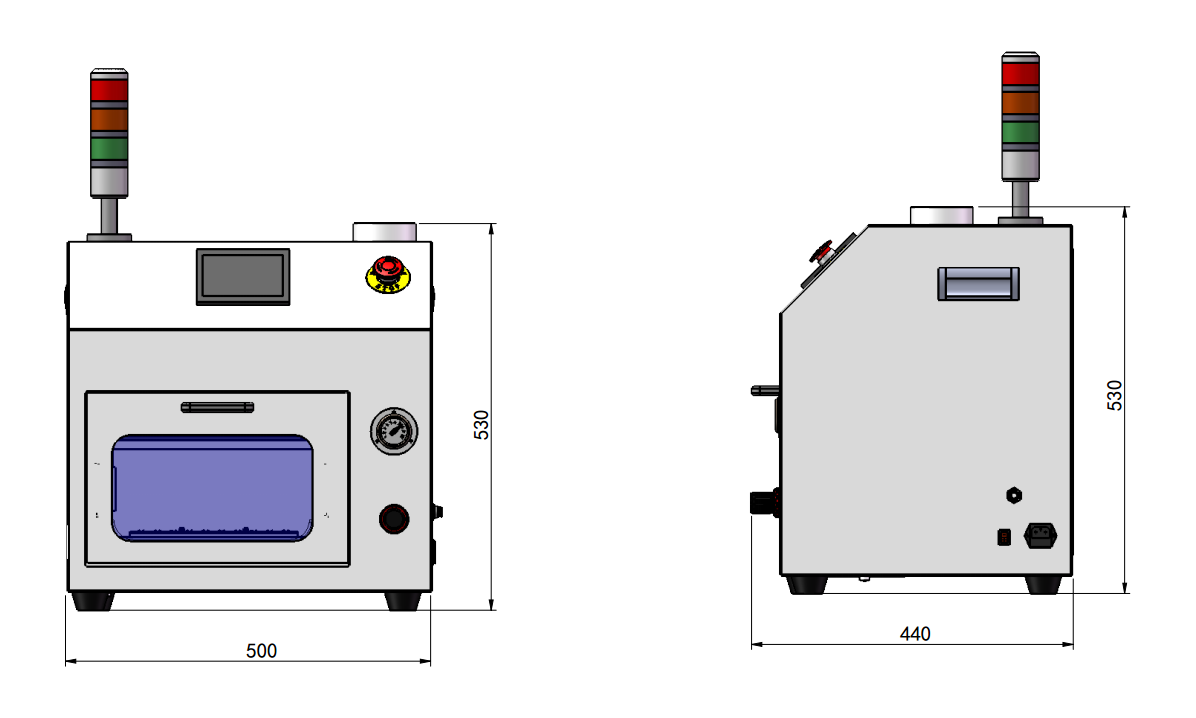

| Model: | HS-800 | |||

| Size:(L*W*H) | 500*440*530mm | |||

| Power | Single phase,220V,50/60Hz,20A | |||

| Power supply: | 200W | |||

| Air pressure: | 0.5-0.6MPa | |||

| Controlling Mode: | Touch Screen+PLC | |||

| Air Source: | Pure Compressed air | |||

| Jet Pressure: | ≤0.4MPa | |||

| Air Wastage: | under 280NL/min | |||

| Liquid Type: | Industrial Purified Water | |||

| Liquid Consumption: | 300cc/hour | |||

| Liquid Storage: | 800cc | |||

| Admission pipe/Drainpipe | φ8/φ6 | |||

| Specs of Nozzle Tray | Default 30 nozzles | |||

| Specs of cleaning nozzle | 0201-2512inch | |||

| Noise | 35-60dB | |||

| Net Weight: | 45kg | |||

Features

1, Default place 30 nozzles,reduce time to chage nozzles by using the nozzle holder, achieve high efficiency.

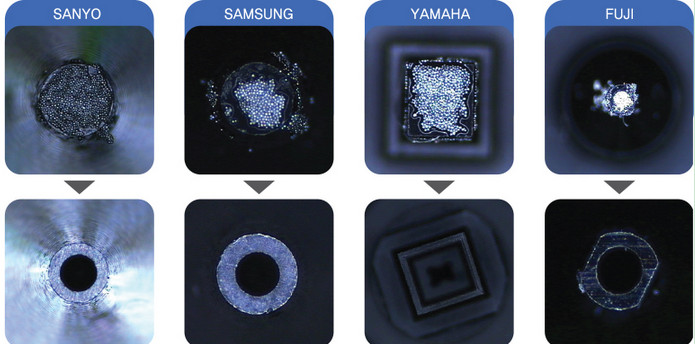

2, Can compatible with nozzles of PANASONIC,FUJI,JUKI,SIPLACER,YAMAHA,SAMGUNG mounting machines. 3, Work with the compressor air for wahsing and drying.

4, Full inspection window for easy maintenance and operation.

5, Using Industrial pure water, not harmful for all types of nozzles and reflector panel.

6, With a malfunction alarm and emergency braking system, with overload protection system.

7, The machine with streamline design, elegant appearance;

8, Human design, press external buttons to achieve start and stop;

9, Touch screen + PLC distributed control, stable and reliable performance;

10, Centralized waste collection, easy maintenance.

Cleaning Performance

Visual Size

About Packaging