Shenzhen Perfect Precision Product Co., Ltd. |

|

Verified Suppliers

|

|

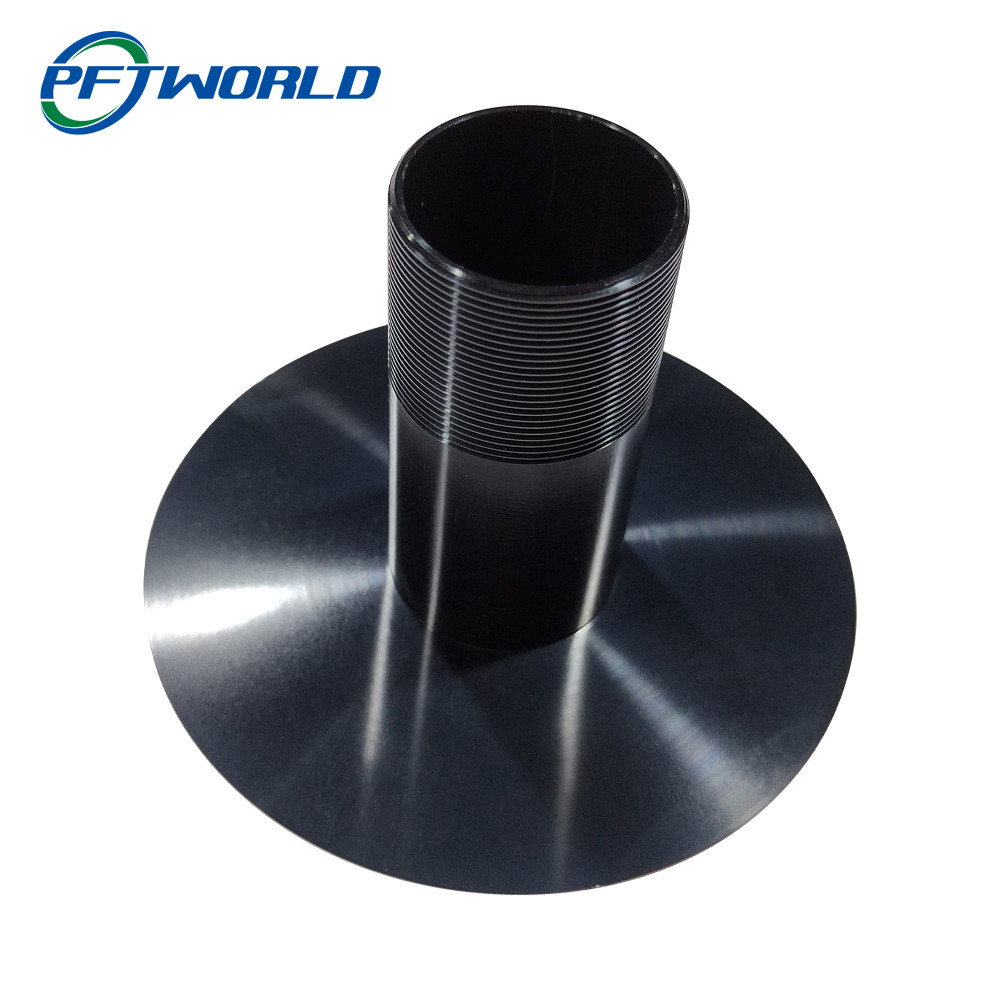

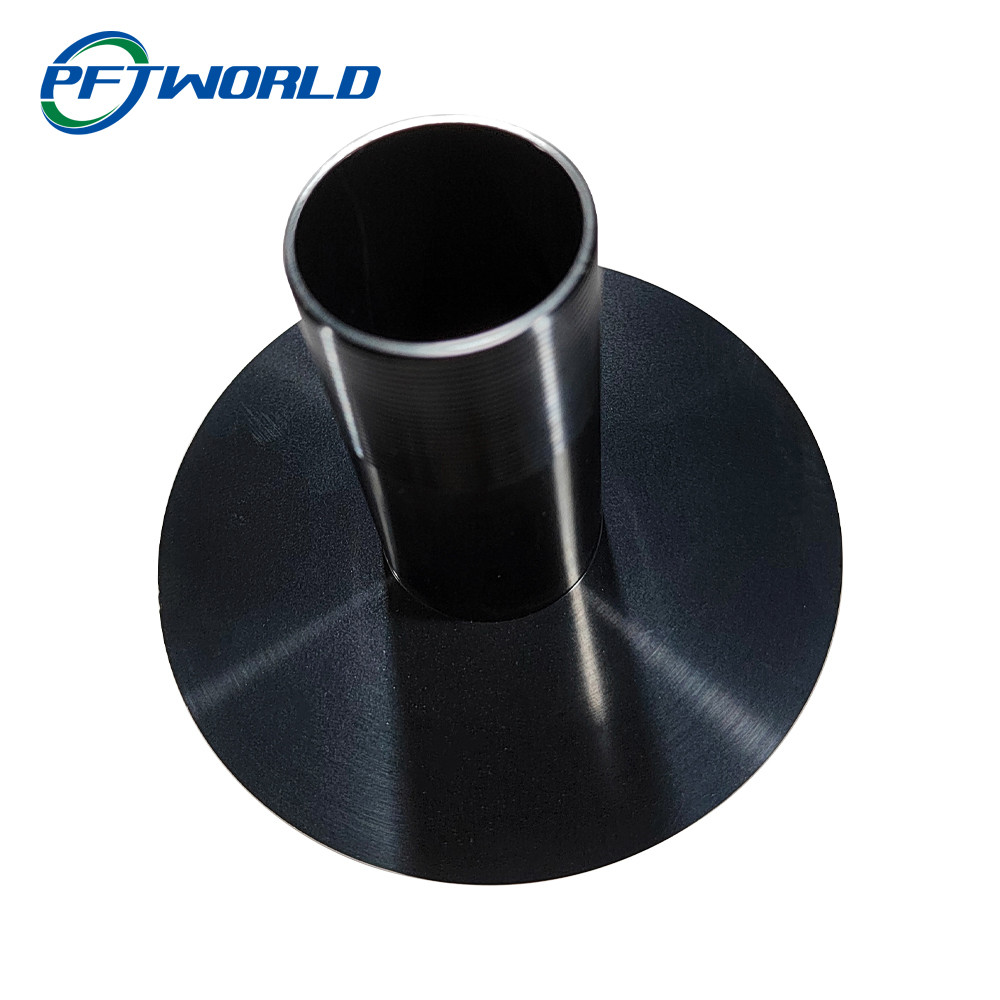

CNC Machined Milling Anodized Aluminum CNC Metal Parts

About us:

Shenzhen Perfect Precision Products Co., Ltd. is a national high-tech enterprise manufacturing precision parts, using the latest CNC turning, CNC milling, multi-axis turning, milling compound, injection molding, sheet metal, and other processes.

Professional supply of various materials and different special processing of high-quality components. With over 15 years of rich experience, we are proud to work with customers from different fields to establish close cooperation and provide customers with first-class products and services.

Our company has advanced imported CNC equipment, such as HAAS Machining Center of the United States (including five-axis linkage), Japanese CITIZEN/TSUGAMI (six-axis) precision turning and milling compound machine, HEXAGON automatic three coordinates, etc., the production of a complete range of parts widely used in aerospace, automotive, medical, optics, instrumentation, ocean and many other fields.

We have an experienced engineering team, passed the ISO9001/ISO13485/AS9000/IATF16949, etc

System certification at the same time also implemented factory digitization, such as ERP/MES system, to further improve the guarantee from sample manufacturing to mass production.

Perfect always adheres to the pursuit of perfect quality as the goal, with domestic and foreign customers highly recognized and consistent praise.

Turning Features:

Turning is a method of cutting a workpiece on a lathe using the rotation of the workpiece relative to the tool. Turning is the most basic and common cutting method. Most workpieces with revolving surfaces can be processed by turning methods, such as inner and outer cylindrical surfaces, inner and outer conical surfaces, end faces, grooves, threads, and rotary forming surfaces. Common lathes can be divided into horizontal lathes, floor lathes, vertical lathes, turret lathes and profiling lathes, most of which are horizontal lathes.

We Support CNC Machining Parts of Most Materials

| Quotation | According to your drawing(size, material, thickness, processing content, and required technology, etc) |

| Tolerance | +/-0.005 - 0.01mm(Customize available) |

| Surface Roughness | Ra0.2 - Ra3.2(Custonize avaiable) |

| Materials Available | Such as aluminum, copper, stainless steel, iron, PE, PVC, ABS, etc. |

| Surface Treatment | Such as polishing, general oxidation, hard oxidation, color oxidation, surface chamfering, tempering, quenching, etc. |

| Processing | CNC Turning, Milling, turning-milling compound, drilling, auto lathe, tapping, bushing, surface treatment, etc. |

| Drawing | 1.) Pls provide design drawings and contact our Alibaba sales manager, If there are no drawings can send samples/sample photos to get a free quotation. 2.) To help us offer the best service for you. Pls be sure your drawings are clear and accurate(including processing quantity, materials, precision tolerances, surface treatment, and special requirements)

|

| Our Benefits | 1.) Over 7 years of experience in the CNC machining area and have a senior design and production team to offer perfect modification suggestions. 2.) Quickly quote and quickly Deliver. 3.) We bear 100% responsibility for quality problems. |

Service Items

One-stop processing from sheet to finished product

Laser cutting processing, Bending processing, Welding processing, CNC machining center

Our Advantage -- Customzied drawings, single-piece order

Technological Innovation -- Complicated curved surfaces and functional structure prototypes can be quickly formed.

Processing Speed -- Short production cycle, fast delivery, ensure delivery by the agreed delivery date.

Product Quality -- Good quality, guaranteed material accuracy up to 0.02mm to 0.1mm.

Highly Confidential -- Multiple confidentiality measures protect customer information, and more.

FAQ

Q1: What is the payment terms? Do I pay first or after the items have been delivered?

A1:The payment methods are T/T, Western Union and Alibaba trade assurance.

30% Deposit before production, the balance before delivery. (when we finish the products, we will send the digital photo from a different angle for your confirmation. after you confirm,you can pay the balance,and we will deliver the goods).

Q2: What’s your MOQ?

A2: We have no MOQ for our new customers, we are accepting small orders to support your trial order, new design, and marketing development.

Q3: Can you offer a free sample?

A3: Yes, we can provide a free sample, but we prefer to charge the freight cost if you do not have an international express account for transfer.

Q4: What’s the lead time for small orders and mass production?

A4: 1~3 working days for small orders, and 3~15 working days for mass production of material, and the final lead time will be subject to each invoice.

Q5. Can I get a quote without drawings?

A5. Sure, we appreciate receiving your samples, pictures or drafts with detailed dimensions for an accurate quotation.

Q6. Will my drawings be divulged if you benefit?

A6 No, we pay much attention to protecting our customers’ privacy of drawings, signing an NDA is also accepted if needed.