Full Automatic PS Foam Sheet Extruding Machine For Fast Food Box

Forming Machine

Fast food box machine mainly includes 3 parts:

1. PS Foam Sheet Extrusion Line

2. Automatic Vacuum Forming and Cutting Machine

3. Crusher and Recycle Machine

This line is the whole production line, which can form lunch box

from raw material. This is the recycle. The work flow is as

follows: raw material---(ps foam sheet extrusion line)---foam

sheet---(lunch box forming machine and cutting machine)---lunch

box---(plastic recycle machine)---plastic granulars( this part can

be used as raw material)----foam sheet.

Product Description

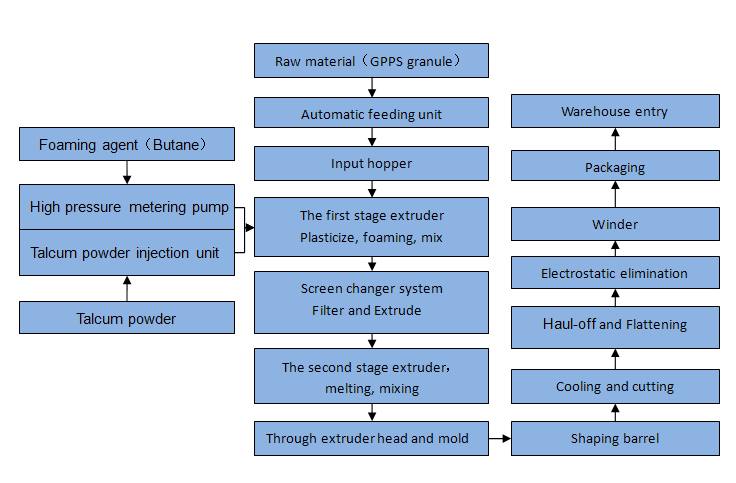

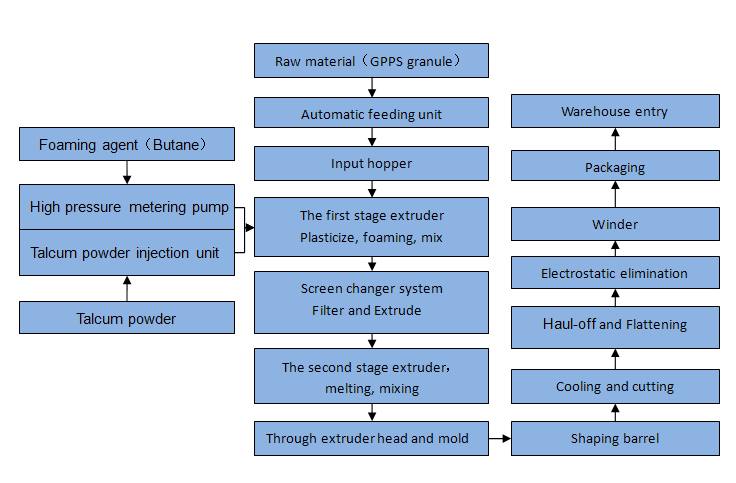

PS Foam Sheet Extrusion Line adopts Gentian type double-stage

series high foam technology. The raw material is general

polystyrene granule. In the extruding process, vesicant is injected

at high pressure. After extruding, foaming, cooling, shaping and

hauling off, it is winding to finished PS foam sheet rolls. After

vacuum forming system, the finished PS foaming sheet can be made

into variety of packaging vessels such as fast food box ,aquatic

plate, supermarket tray ,cake tray , KT board ,instant noodle bowl

,foam tray etc. It is widely used in the packing for food, fruit,

and advertising industrial products and so on. This equipment

adopts high speed hydraulic filter changer which has steady

feature, can realize change the filter immediately without stopping

the machine. The foaming shaping machine adopts PLC control, touch

screen operation, easily to operate.

Application

1- Fruit, vegetable and raw meat pallets ;Food industry and fast

(to-go) packages ;And egg crates .

2- Food container ,bowls ,trays and other tableware

3- Education materials ;decorative materials

4- Isolation materials for contraction (wallpaper ,padding and

ceiling panels)

5- Polysterene containers keep food warm or cold so they are

perfect for serving both hot meals and ice cream

6- Polystyrene is print-ready ,easy to fold ,water and bacteria

resistant ,and a great insulator .

Flow chart

Fully auto forming and cutting machine

This forming and cutting incorporated machine designed by our

company is all-powerful. The main way is vacuum forming as well as

press forming and synthetical forming. It can be used for forming

kinds of plastic sheet. This machine adopt PLC control, it has

group possesses reliable stability, large forming area, high

production and automatic degree. The machine can mainly forming the

PSP material which is used to produce food container, tray, bowl,

cup etc. Forming, cutting, stacking are done in the same machine,

saving labor, improving efficient, lowing labor intensity and

reducing production cost. Production process is to put foam sheet

into forming machine, and product and wastage will come out from

the rear part.

| Model | Unit | HR-1040 |

| Max. forming area | mm2 | 1000×1100 |

| Max. forming depth | mm | 80 |

| Production efficiency | s/die | 3 - 8 |

| Forming pressure | T | 15 |

| Mounted power | kw | 170 |

| Total weight | T | 16 |

| Installation size | m | 13×2×3.2 |

| Forming speed | time/s | 16-18 |

1. It is an all-powerful thermal forming machine with integration

of vacuum forming and cutting.

2. It can produce PS foam food box/container, foam (egg/meat) tray,

hamburger box, foam plates/bowl, fruit tray, etc. The foam

container has feature of shock-resistance, crush- resistance, heat

insulation, etc. It is widely used to pack the heat and frozen food

in supermarket, store and etc.

3. It adopts remote infrared ceramic heater in heating zone, with

which the machine get the most stable and even temperature.

4. It adopts temperature digital system, which is convenient for

the workers to know the temperature of each heating zone quickly.

Also it is easily operate and make more efficiency.

5. It adopts Japanese servo motor & drive, Mitsubishi PLC

mechanical and electronic integration control, touch screen for

operating.

6. It features reliable stability, large forming area and fast

speed,as well as highly degree of automation & economic on

manpower.

7. It adopts automatic pneumatic device in feeding area, which

reduces the labor force.