Longkou City Hongrun Packing Machinery Co., Ltd. |

|

rolling ps foam sheet making machine double-screw eps extrusion machine for containers

This line can make PS foam tray, absorbent foam tray for meat, foam burger box, foam fast food box, foam egg tray, foam bowls and so on.

A. The raw material is General purpose polystyrene (GPPS).

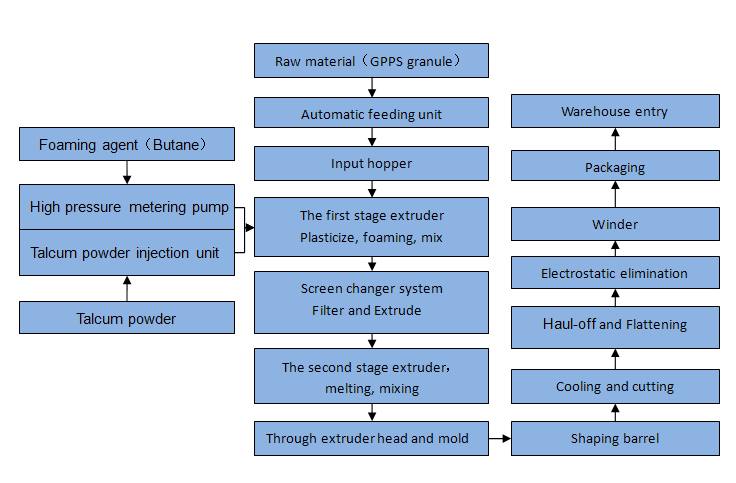

B. The general process flow of the PS foam food container machine as below:

aa. The PS foam sheet is made by the PS foam sheet extruder

bb. The foam sheet shaped by the vacuum forming machine

cc. The hydraulic cutting off machine cut the shaped sheet into finish products .

dd. The sheet scrap will be recycled by the recycling machine .

C. Brief description of PS foam food box production line.

1. PS Foam Sheet Extruder :

1. It adopts Gentian type double-stage series high foam technology.

2. The raw material is general polystyrene granule (GPPS).

3. In the extruding process, foam agent such as butane gas or LPG is injected at high pressure.

4. After extruding, foaming, cooling, shaping and hauling off, it is winding to finished ps foam sheet rolls.

2. Vacuum Forming and Cutting off Machine :

• It is an all-powerful thermal forming machine with integration of vacuum forming and cutting.

• It can produce PS foam food box/container, foam (egg/meat) tray, hamburger box, foam plates/bowl, fruit tray, etc. The foam container has feature of shock-resistance, crush- resistance,heat insulation, etc. It is widely used to pack the heat and frozen food in supermarket, store and etc.

• Heating zone adopts remote infrared ceramic heater.

• Temperature digital system is convenient for the workers to know the temperature of each heating zone quickly.

• It adopts Japanese servo motor & drive, Mitsubishi PLC mechanical and electronic integration control, touch screen for operating.

• Reliable stability, large forming area and fast speed.

• Feeding area adopts automatic pneumatic device , which reduces the labor force.

3. Recycling Machine

1. It adopts fully automatic temperature controlling, one manual filter changer device at the front of the machine to filtrate the impurity of the recycling material.

2. the die head made by special alloy steel, follow one set of electric heater bands and automatic temperature controller,die head passageway is designed special, the press of granule formed need can be ensured.

3. water channel adopts corrosion resistant plate, cooling water circulation, ensure the material line cooled balance and sufficient.

4. granulator cutter adopts frequency speed control of motor drive, the speed of hauling off controlled accurate, the length of granule equality.

5. It is the ideal equipment to recycle the plastic scrap .It features compact structure and easy operation.

6. Recycling machine includes crusher (for crushing the PS foam sheet scrap) and granule maker.

7. It can process PE/PS/PP material and is mainly used to recycle the high foam polystyrene and high foam polystyrene products.

8. It is the ideal equipment to recycle the plastic scrap .It features compact structure and easy operation.

Application

1- Fruit, vegetable and raw meat pallets ;Food industry and fast (to-go) packages ;And egg crates .

2- Food container ,bowls ,trays and other tableware

3- Education materials ;decorative materials

4- Isolation materials for contraction (wallpaper ,padding and ceiling panels)

5- Polysterene containers keep food warm or cold so they are perfect for serving both hot meals and ice cream

6- Polystyrene is print-ready ,easy to fold ,water and bacteria resistant ,and a great insulator .

Flow chart

Different model of extruder

| Model | HR-70/90 | HR-105/120 | HR-120/150 | HR-135/150 | HR-150/200 |

| Screw Diameter | Φ70/90 | Φ105/120 | Φ120/150 | Φ135/150 | Φ150/200 |

| Foam Rate | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 |

| Width of Product (mm) | 640-1040 | 640-1040 | 640-1040 | 640-1200 | 1000-1350 |

| Thickness of Product (mm) | 1.0-3.0 | 1.0-3.5 | 1.0-3.5 | 2.0-5.0 | 2.0-5.0 |

| Output (kg/h) | 50-90 | 100-180 | 180-230 | 230-320 | 400-600 |

| Cutting Mode | Single Cutting | Double Cutting | |||

| Cooling Mode | Cooling by Wind and Water | ||||

| Mounted Power(kw) | 120 | 150 | 180 | 260 | 380 |

| Overall Size(m) | 22*4.0*2.8 | 24*4.1*2.8 | 26*4.2*3 | 28*4.2*3.2 | 28*5.2*3.2 |

| Total Weight (T) | 10 | 12 | 15 | 18 | 23 |

What is the features of our ps foam sheet extruding machine ?

1. low cost,light weight,good rigidity,wide use

2. heat preservation,waterproof.

3. resist high temperature,prevent oil

4. renewable resources

5. as the Soilless cultivation