Longkou City Hongrun Packing Machinery Co., Ltd. |

|

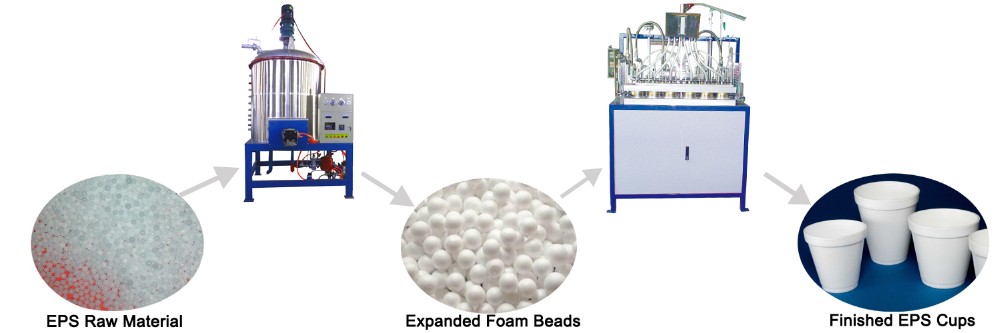

EPS foam bowl making machine Plastic EPS Disposal Foam Coffee Cup Making Machine

Features of eps cup machine

1. EPS Foaming-Cup Production Line is widely applied in producing large amount of hot coffee cup, hot tea cup, hot soup blow, noodle tub and other food and beverage packing .

2. Light weight, good rigidity and well heat isolation.

3. The machine holds many merits such as high foaming times, high

producing efficiency, low steam consumption, low cost and different

model products are made at same time.

4. Pipes and tubes of the transferring system are all made from

stainless material so that they resist eroding and easy to be

cleaned.

5. Pre-expand and forming procedures are all operated by automatic

controller, the mechanical and electrical device or apparatuses are

all from international famous brand

Primary Configuration and Main Parameters of the Production Line

1. This EPS foam cup making machine is using Expendable Polystyrene

as raw material.

2. Finished products: foam cups and bowls.

3. Main machines: boiler, mixer, pre-foaming machine, drying

machine, shake boult, center filling device, forming machine

4. PLC control

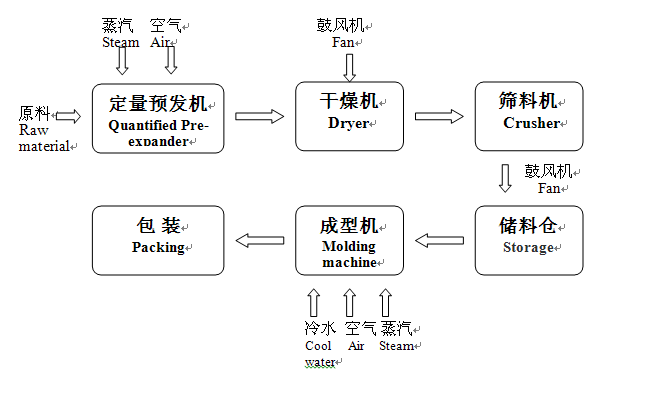

Process:

Mixing---pre-expanded---drying---filtering---storage---

forming-----collecting

| Main Items | Description | |

| Cup Size | 6~16 Oz | |

| Cavity No. | 6~8 Pcs | |

| Production Cycle | 6~16 seconds/cycle | |

| Power Consumption | 300 W (Forming Machine) | |

| Primary Configuration | Item | Description |

| 1. Raw Material Mixer and Feeding Device | Voltage | 380V(220V), 50Hz |

| Motor | 3Kw, 960Rpm | |

| Mix | 350Kg/time | |

| 2. Pre-Foaming Machine | Steam press | 0.7-0.8MPa |

| Air press | 0.7-0.8MPa | |

| Foaming time | 20-50Seconds/cycle | |

| Output | 50-160Kg/h | |

| Motor | 3Kw | |

| Machine size (L*W*H) | 1400*800*2500mm | |

| 3. Drying Machine | Output | 150-200Kg/h |

| Motor | 6.6Kw | |

| Machine size (L*W*H) | 2800*600*1100mm | |

| 4. Vibration Machine | Output | 50-200Kg/h |

| Motor | 1.5Kw | |

| Machine size (L*W*H) | 1100*1000*1000mm | |

| 5. Centre filling device | Motor | 2.2Kw, 3 sets |

| Big hopper | 1500*1500*450mm, 3 sets | |

| Small hopper | 1200*1000*1000mm,1 set | |

| Material stock bag | 1000*1000*1200mm | |

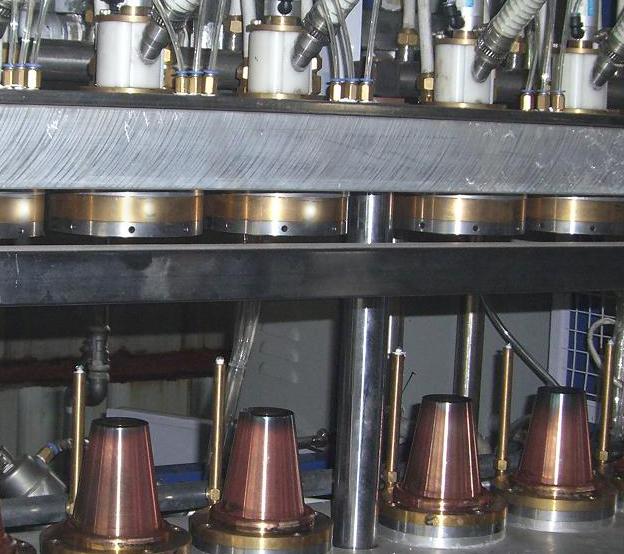

| 6. Forming Machine | Stroke height | 3-180mm |

| Production cycle | 6-16seconds/cycle | |

| Energy consumption | ≤0.3Kw | |

| Steam press | 0.6-0.9MPa | |

| Cooling water press | 0.4-0.5MPa | |

| Air press | 0.6-0.9MPa | |

| Working area (L*W) | 1200*280mm | |

Flow chart

Step 1. Mix the EPS resin and the additive (ZnSt) according to the given proportion.

Step 2. Put mixed material into Pre-foaming Machine along with water steam to expand the resin.

Step 3. Vibrate the pre-foamed material and store for several hours.

Step 4. Form EPS cups/bowls.

Step 5. Pack the EPS cups with plastic packaging bags.