Longkou City Hongrun Packing Machinery Co., Ltd. |

|

Big output Apple Tray Making Machine , egg box machinery for scale of expansion

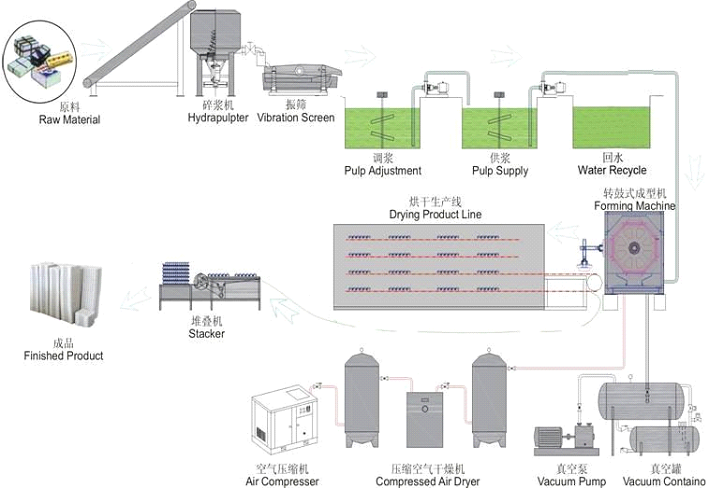

Pulp Moulding production line is known as egg tray line for using massively in produce egg tray. Pulp Moulding production line, which uses waste paper, cardboard, leftover material of paper mill, by hydraulic pulper, mix making a certain dense pulp, and pulp is absorbed by vacuum of special metal moulding to become wet products, through drying , and shaping to become finished products. Pulp Moulding Line processing makes use of recycled water and does not lead to water or air pollution. Finished packaging products can be recycled after being used in storage, transport, and sales. After shredding, they are easy to be decomposed as paper, even if discarded into the natural environment. Automatic pulp molding production lines can be mass production of various food container, egg tray, lunch boxes and so on. The major equipment of the machine are three parts include: Pulp Making System, Molding System, Drying system and packing system.

Feature of egg tray machine :

egg tray machine is absorbing paper pulp-the raw material, on the surface of mould by vacuum to get a variety of shape and ratio of wet and dry by regulating time. After such working procedure as transferring mould, releasing mould to complete paper tray production. Our egg tray machine selecting of high quality electronic devices and pneumatic components,high performance and long service life.

Advantage of egg tray machine :

The raw material is for the molded pulp products is waste paper,corrugated paper,waste newspaper,magazine, the scrapes from color printing plants and waste paper boxes.The raw materials are free pollution, can be recycled. and easy to find.

Application of egg tray machine :

1. Middle size farm.

2. Small workshop available.

3. High labor cost countries.

4. Water value sensitive countries.

5. It can produce egg carton, egg box, egg tray, bottle tray, agricultural train seeding cup, industrial production packing. The equipment is best-selling nation and is sold abroad.

Pulping system: Hydrapulper ,Pulp pump ,Air compressor,agitator,Self priming pump,pulping machine.

Forming system: Full automatic egg tray forming machine, Vacuum pump , High pressure washer, Negative pressure tank , mould, Transfer mould, baler .

Drying system: There are 2 kinds of drying system. One is metal, the other is brick. The conveyor plate

can be one layer and multi-layer, direct combustion hot air circulation. Using the imported

or joint venture brand burner (domestic uses the stove bar), equipped with an automatic

control cabinet.

Note: The country with very high-temperature can choose the natural drying method, no need for

the drying system. This way can reduce the cost.

The paper egg carton making machine used for the making the molded pulp products,such as egg tray,egg carton/box from waste paper.small invest.

1, mainly producing the pulp molded products,such as egg tray ,egg box, fruit tray,coffee tray.

2, Material for the molded pulp products is waste paper,corrugated paper,waste newspaper,magazine.

3, Semi-automatic control

4, stainless steel pulp tank,the surface of platens covered with stainless steel.

5, transferred to a flat-bed automatically

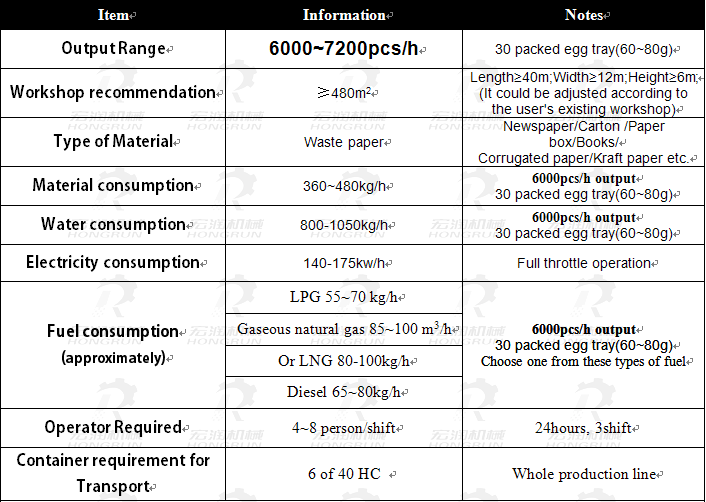

Technical data of Used Paper Egg Tray Make Machine/egg Tray Machine

Production Line/egg Packing Box Maker (support Customize)

a) Workshop: more than 50m2.(length>=8m,width>=6.2m).

b) Production capacity: 1000pcs/hour.(30-eggs tray, ~65g/pc).

c) Electricity consumption: ~19.6KW. ( 28KW installed ).

d) Water consumption:~250kgs/hour

e) Kind of Raw material: newspaper, carton paper

f) Raw material consumption: ~70kgs/hour

g) Workers:3~4 person

h) Transport: the machine needs 1 of 20' container for loading it.

Flow chart

For pulp molded 30-cell egg trays : first the worker will weight

the raw material and put them into the conveyor. Then the pulping

,forming, drying and stacking will be finished automatically. After

drying, the finished products will be packed by workers.

A hot pressing section should be added in the production of pulp

molded egg

box/carton(6-cell,10-cell,12-cell,6+6-cell,15-cell),fruit tray and

cup carrier after drying because of shrinking.

The egg box/carton can be labelled or printed after hot pressing.

These processes could be finsihed manually or automatically.

Technology Parameters

We can offer other model egg tray machine as following:

| Model | Capacity | Forming machine | Drying system | Workshop spcae | Rated power |

| HRZ-1500S | 1500pcs/hr | 3molds *4faces Rotary type | Single-Layer Metal | 35m*10m*6m | 130KW |

| HRZ-1500M | 1500pcs/hr | 3molds *4faces Rotary type | 6 Layers Mental | 25m*10m*6m | 120KW |

| HRZ-2000S | 2000pcs/hr | 4molds *4faces Rotary type | Single-Layer Metal | 40m*10m*6m | 165KW |

| HRZ-2000M | 2000pcs/hr | 4molds *4faces Rotary type | 6 Layers Mental | 25m*10m*6m | 145KW |

| HRZ-3000S | 3000pcs/hr | 3molds *8faces Rotary type | Single-Layer Metal | 45m*10m*6m | 209KW |

| HRZ-3000M | 3000pcs/hr | 3molds *8faces Rotary type | 6 Layers Mental | 30m*10m*6m | 189KW |

| HRZ-4000S | 4000pcs/hr | 4molds *8faces Rotary type | Single-Layer Metal | 55m*10m*6m | 239KW |

| HRZ-4000M | 4000pcs/hr | 4molds *8faces Rotary type | 6 Layers Mental | 30m*10m*6m | 223KW |

| HRZ-5000S | 5000pcs/hr | 5molds *8faces Rotary type | Single-Layer Metal | 70m*15m*6m | 298KW |

| HRZ-5000M | 5000pcs/hr | 5molds *8faces Rotary type | 6 Layers Mental | 35m*15m*6m | 273KW |

| HRZ-6000S | 6000pcs/hr | 6molds *8faces Rotary type | Single-Layer Metal | 80m*15m*6m | 365KW |

| HRZ-6000M | 6000pcs/hr | 6molds *8faces Rotary type | 6 Layers Mental | 37m*15m*6m | 326KW |

| HRD-8000M | 8000pcs/hr | 4*8 & 4*8 Double-roller | 6 Layers Mental | 40m*15m*8m | 368KW |

| HRD-12000M | 12000pcs/hr | 5*8 & 5*8 Double-roller | 6 Layers Mental | 42m*15m*8m | 428KW |

Finished products

1.What kinds of machines do you produce?

We produce

(1)pulp moulding machines,4000pcs/hr Automatic Rotarypaper egg tray

making machine s,egg packing machines,egg box/carton machines,fruit

tray machines,industrial machines, seeding tray machines .and the

whole production line etc

(2)all kinds of moulds ,such as egg tray moulds,egg box/carton

moulds, fruit tray moulds,seeding tray moulds,industrial moulds

etc.

(3)drying line, forming machine

2.What capacity per hour do you offer ?

Our machines’ capacity is from 400pcs/hr to 12000pcs/hr.

3.Do your products come with a warranty ?

Yes , we have one year warranty according the international

practice.

4.Can I customize this kind of product from your factory?

Yes ,we offer custom-made service to our customers, you need to

provide us some samples,such as photos,dimensions etc.