Shanghai Printyoung International Industry Co.,Ltd |

|

Verified Suppliers

|

|

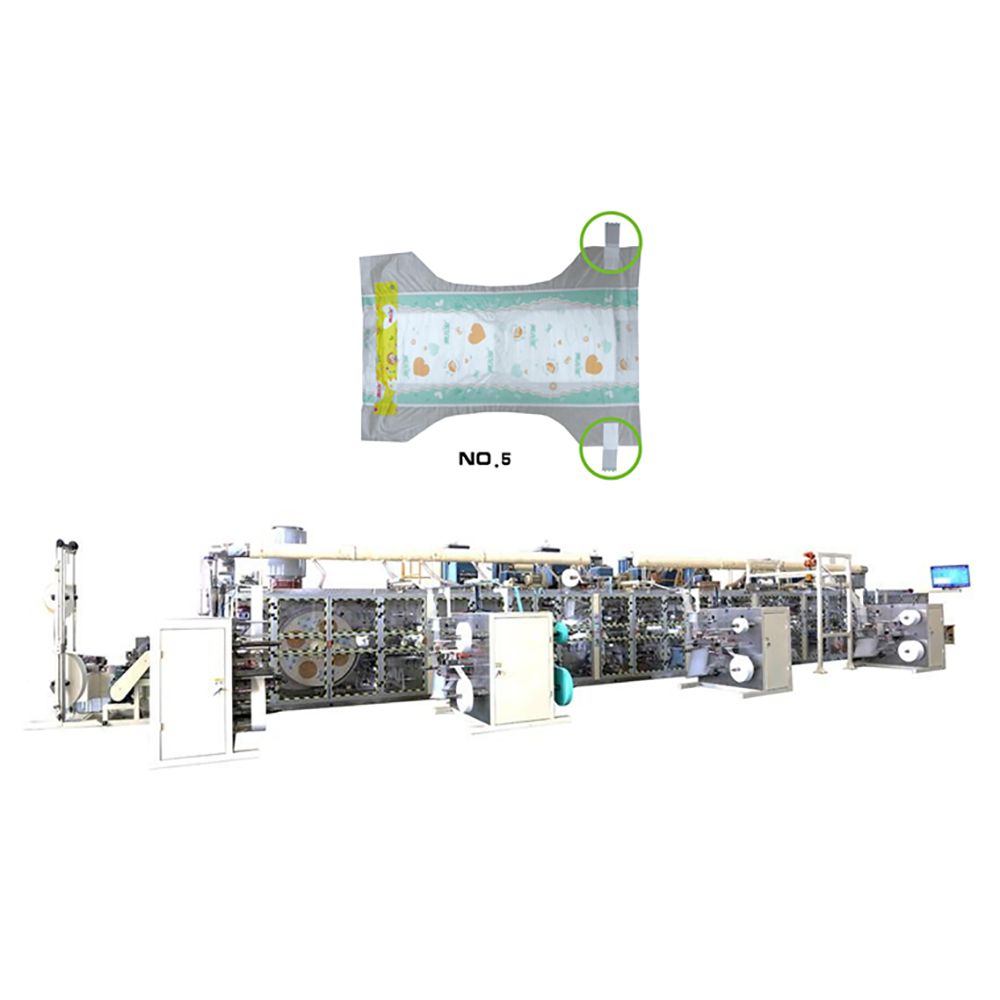

baby diaper machine | |

|---|---|

Design speed | 600pcss/min |

Working speed | 550pcs/min |

Qualified rate | ≥ 97%(exclude the wastage due to the glue applicators and materials splicing joint) |

Efficiency | ≥ 85% |

Installation capacity | ~300 KW (main machine) ~390KW (main machine +glue system+ stacker) |

Running capacity | ~225KW(main machine); ~292.5KW (main machine +glue system+ stacker) |

Electricity | 380V,50HZ (Accept customized) |

Wire | Three phases four wires 380V/50Hz (ground wire)

3X120mm³+1X70mm³+1X25mm³ |

Air pressure | 6 kg/cm2 ≥0.8mpa |

Total weight | 82tons |

Machine size | 25×2.1×4.8 M(L×W×H) |

Working space | 33×10×5.5 M (L×W×H) |

Machine color | Rice white ,can be changed by order |

Product size | S,M,L,XL |

Containers | 5X40HQ |

Name | Quantity | Name | Quantity |

|---|---|---|---|

Maintenance Tools | 1 set | thermocouple | 2 pieces |

Electric heater | 5 pieces | transition wheel | 3 sets |

Cutting blade | 2 pieces | Timing belt | 3 pieces |

Truncation blade | 1 set | Conveying belt | 2 pieces |

Blower wire | 1set | Power cable | 1set |

Electrical schematic diagram | 1 | back transmission diagram in PDF | 1 |

instruction of main electrical elements | 1 | machine layout in PDF | 1 |

A:1)We provide training in our factory for free;

2)We can send technicians (engineers) to your factory for installation and training.