Qinyang PingAn Light Industry Machinery Co., Ltd. |

|

Verified Suppliers

|

Description

This 4200m double wire paper making machines produces high strength fluting paper, craft paper and test liner paper as well based on the weight of 100-160g/m². This machine consists of two wire forming section, press section, dryer section, paper reeling section, base section and auxiliary system etc.

Main parameters

Output: high strength fluting paper, craft paper and test liner paper

Grammage: 100—160g/m2

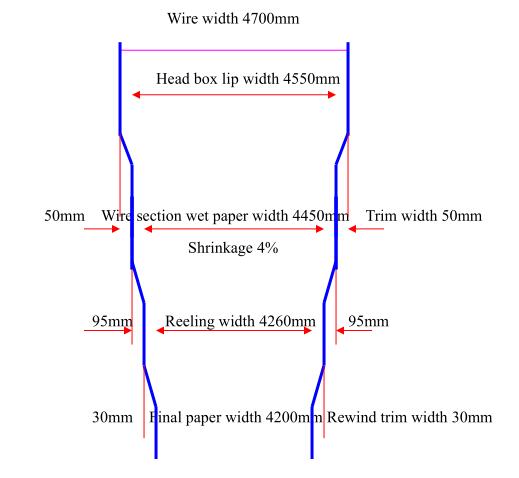

Net paper width: 4200mm

Working speed: 130-250m/min

Designed speed: 280m/min

Crawling speed: 25m/min

Dynamic balance speed: 350m/min

Headbox lip width: 4550mm

Gauge: 5300mm

Drive type: Section drive with AC variable frequency

Layout: one floor

Double wire paper making machine structure

| Forming section | Air cushion headbox |

| Press section | Two big jumbo roll press |

| Dryer section | 28sets dryer cylinder (8+10+sizing machine+1+9) |

| Reeling section | Horizontal pneumatic reeling machine |

| Drive system | Section drive with AC variable frequency |

4200mm double wire fluting paper, craft paper and test liner paper making machine width diagram

4200mm double wire paper making machine parts manufacturing request

Wire section guide roll, press section guide roll, spread roll, dryer section guide roll and paper leading roll:

Frame

Casting parts

Spindle nose of roll