Kunshan Dapeng Precision Machinery Co.,Ltd |

|

Auto Roll Cutting Machine

SPEC

1. Width of cutting shaft

2. I. D. Of paper core

3. Cutting width

4. Positioning precision

5. Power supply

6. Air compressor

7. Max. Blade diameter

Main Machine

1. Auto motor

2. Size setting

3. Control system

4. Recorder

5. Sliding part

6. Cooling system

7. Cutting shaft

(more info, please contact with us freely )

1300/1600mm

3"

1mm-1620mm

± 0.1mm

380V 50HZ 3P

5KG(self-supply by the customer)

350mm

AC 3HP*6P variable frequency speed control

Taiwan TECO servo motor control 750W

PLC auto setting of 10sizes

7"touch panel

Imported high precision ball screw

Imported high precision linear steel-ball slide rail

Auto spray of water supply

3" inner tension shaft

| Machine width | 1.3M |

| Cutting precision | +/-0.1mm |

| Max. Cutting O.D. | 280mm( can cut 145mm) |

| Min. Cutting width | 1mm |

| Inner core I.D. | 76mm |

| Model | DP-1300C Auto Roll Cutting Machine | |

| Abstract | Specification | Quantity |

SPEC 1.width of cutting shaft 2.I.D. of paper core 3.cutting width 4.positioning precision 5.power supply 6.air compressor 7.Max.blade diameter Main Machine 1.auto motor 2.size setting 3.control system 4.recorder 5.sliding part

6.cooling system 7.cutting shaft 8.cutting shaft sleeve 9.circular blade clamp 10.circular blade 11.safety baffler 12.blade motor 13.auto angle adjustment of circular blade 14.cutting system 15.control button switch 16.maintenance tool |

1300mm 3" 1mm-1320mm ±0.1mm 380V 50HZ 3P 5KG(self-supply by the customer) ¢300mm

AC 3HP*6P variable frequency speed control Taiwan TECO servo motor control 750W PLC auto setting of 10sizes 7"touch panel imported high precision ball screw imported high precision linear steel-ball slide rail auto spray of water supply 3" inner tension shaft PE tube 75.4 ¢158 ¢300 circular blade

AC 2HP*6P variable frequency speed control full-auto angle adjustment of width +/-8°stepping motor control

Taiwan TECO servo motor control 750W Taiwan Tend, Shihlin Electric common maintenance tool and instructions |

1 1 1 1 1 2 1 1 5 1 2 1 1 1

1 1

|

Suitable for cutting roll-stock materials such as adhesive tapes, textiles, foam, rubber, foil, gaskets, vinyl, non-woven, glass cloth, silicone, PTFE, PSA, plastics, DPC, cork, felt, graphite, protection film, protection tape, medical and food grade applications etc.

Feature

1. Main driving part: Taiwan AC motor with inverter is employed.

2. Central control unit: programmable central control is used and 10 sizes can be set on the same shaft for auto transfer and cutting.

3. Operating panel: all functions are operated on the 7" Wein View LCD touch panel.

4. Motor control system: the central control system is PLC programmable controller.

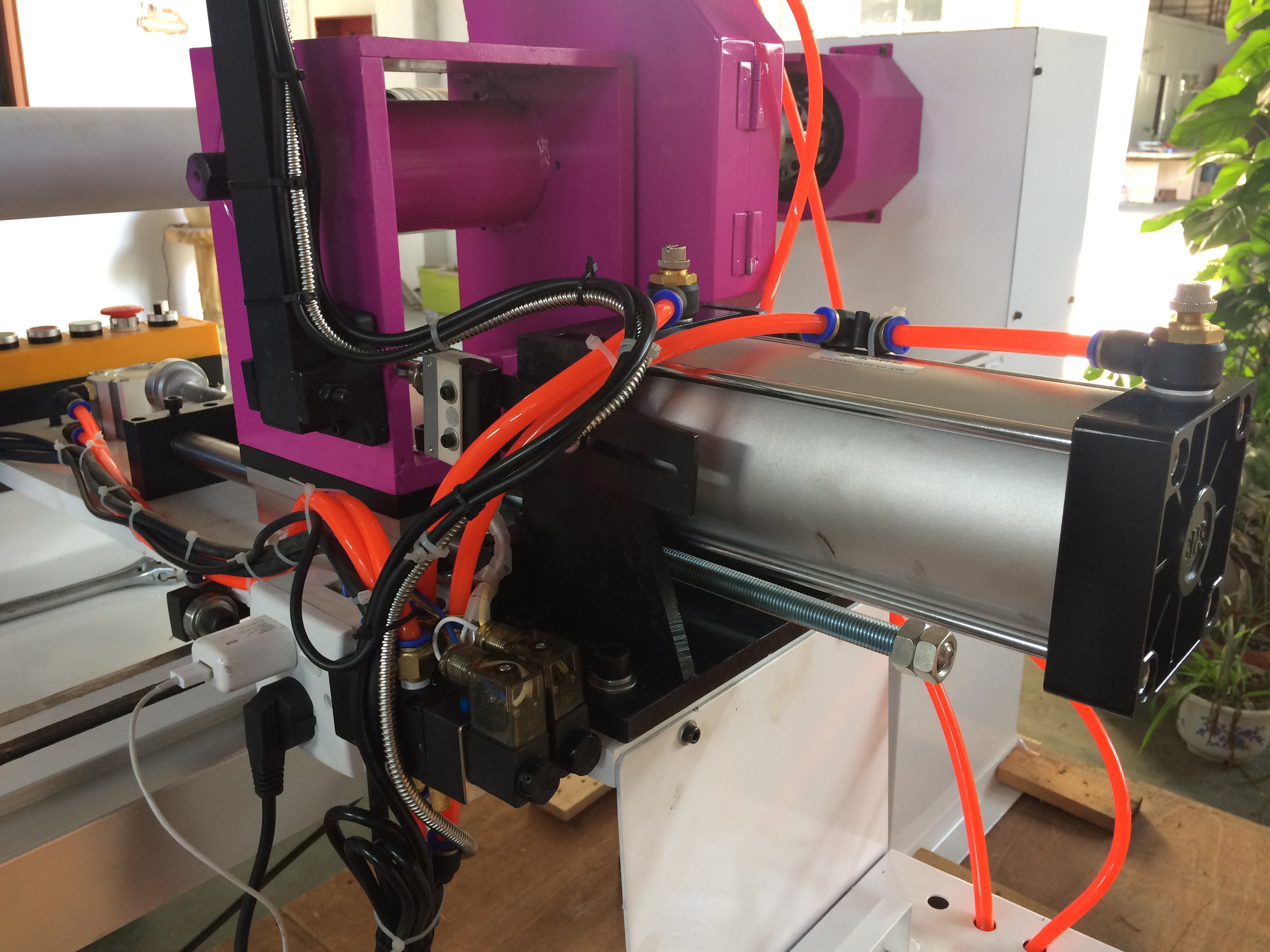

5. Cutting positioning system: cutting positioning is controlled by servo motor. The imported high precision ball screw is applied to set the size and the linear slide rail is to bear the load of the cutter seat.

6. Blade feeding positioning system: blade feeding is controlled by servo motor, and the cutting speed is adjustable in three stages.

7. Auto angle adjustment of circular blade: stepping motoris used to calculate the circular blade angle and the angle change is subject to different materials (the angle change range is ±8°).

8. Quick shaft change system: three kinds of shafts are available and quick change of shafts is applied for different materials.

| After sale service | This product warranty period of one year, the buyer must have to regular maintenance of the machine in warranty period,, due to outside and man-made factors of improper operation of the machine damage is not within the warranty. After one year, freight and spare parts costs buyers themselves pay. |