Kunshan Dapeng Precision Machinery Co.,Ltd |

|

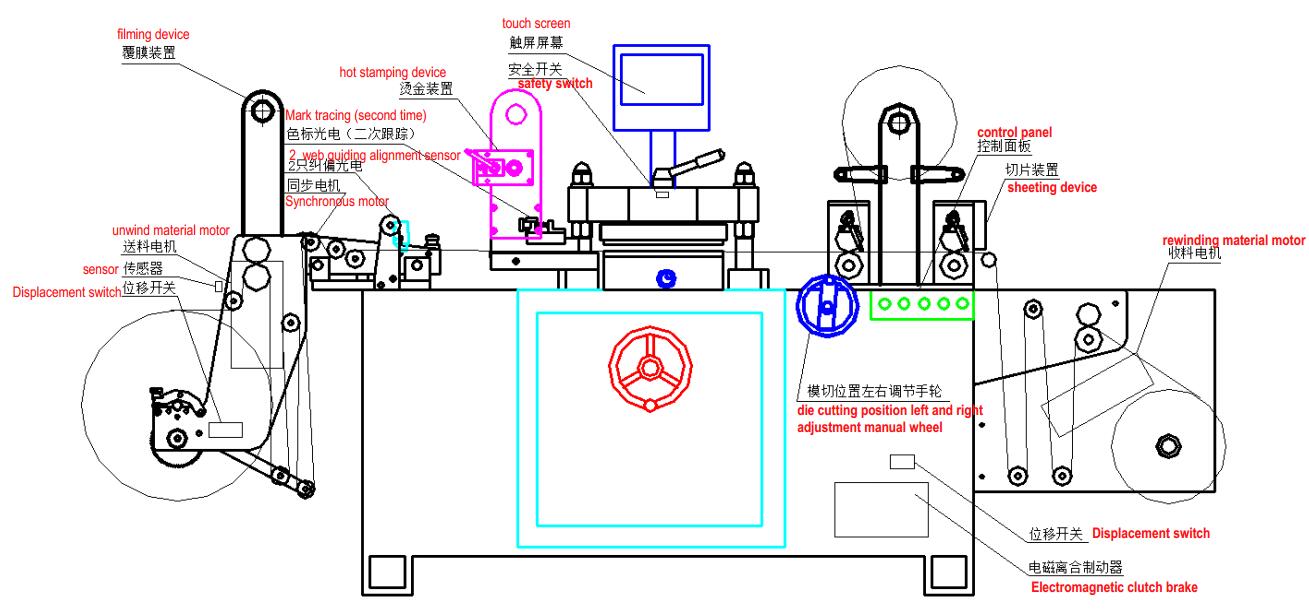

DP-320D automatic high speed printed label die cutting machine

First , Machine main technical data

A. max die cutting speed 300 cuts/minute

B. die cutting area 320*300mm(width * length )

C. unwind roll max diameter 500mm

D. max paper roll diameter 320 mm

E. left to right position precision : ±0.50mm

F. Step Accuracy : ±0.10mm

G. Total power : about 6.0kw

H. Power Voltage: 1P 220V 50HZ

I. Machine Net weight about 1650kg

J. machine size(length *width * height ): 2700*1050*1400mm( Removable 1600*1050*1400mm)

automatic multi-function combination laminating machine and die cutting machine

Second , machine configuration

1 , unwinding part

C. unwind pulling material roller + steel roller D. unwind pulling material motor300W

E. unwind damping device F. Electric Eye ( paperless automatic stop)

2, laminating part ( optional function )

1. filming device ( unwinding function )

2. filming device ( unwind rewind function )

A. filming unwinding roller B. filming rewinding roller

C. filming rewinding motor D. Aluminum guiding roller

C. Rectification electric eye

C. Color tracking electric eye

1.Mechanical type punching hole

2. Pneumatic punching hole

A. punching hole mold B. Pneumatic cylinder

C.Timing belt

C. Buffer Disposal Device - Optional function

(For some thick adhesive material difficult to scrap material )

9. sheeting blade part

C. up cutting blade (inserting steel) D. down cutting blade (inserting steel)

C. Rewinding pulling material rubber roller+ steel roller

D. rewinding motor 800W ( when sheeting can stop)

C. hot stamping pulling material roller

D. hot stamping pulling material motor ( stepper motor )

2. Servo motor hot stamping device

A. Hot stamping unwind roller

B. Aluminum guiding roller

C. hot stamping pulling material roller

D. hot stamping pulling material motor ( servo motor 0.75KW Zhejiang Dongling)

C. Servo motor driver (Zhejiang Dongling)

D. Frequency speed converter ( HUALAN)

E. Power switch 220-2-110( Taiwan )

| Servo Motor | Japan mitsubishi | ||||||

| PLC control | Japan mitsubishi | ||||||

| touch screen | Taiwan Weilun | ||||||

| transducer | Taiwan Shilin | ||||||

| cutting tool clutch | Taiwan Tangying | ||||||

| main machine bearing | NSK | ||||||

| packing : | |||||||

| wooden case packing of unwinder | 160X95X122 | 1 | 500 | 520 | |||

| wooden case packing of main machine | 230X128X174 | 1 | 1600 | 1630 | |||

| Standard fuinction | |||||||

| 1. ,unwinding machine | |||||||

| 2, wind attract | |||||||

| 3, Die Cutting | |||||||

| 4, waste Draining | |||||||

| 5, Conveyor belt | |||||||

pvc foil die cutting machine

Die cutting machine

This die cutting machine is suitable for die cut various insulating

material. Like, PVC, PE, PET, tape, Mylar, Aluminum foil, Copper

foil

Die cutting speed: 170 strokes/min

Functional characteristics:

The imported motor is used for the receiving ( separating )

bottom sheet of sticking film, Feeding-filming( enjoying

multi-layer sticking and partial sticking) -die cutting- waste

draining- slitting- rolling, all of them are completed by the

computer control by one turn.

Scope applicable:

Various insulating materials such as electronic shield materials,

PVC, film, Mylar, cooper foil, aluminum foil, foam, etc.

Main Parameters:

| Model | 320B | 420B |

| Max Feeding Width ( mm ) | 320 | 420 |

| Cutting Area ( mm ) | 300*300 | 400*400 |

| Cutting Speed ( T/M) | 30-170 | 30-170 |

| Position Accuracy ( mm ) | ±0.10 | ±0.10 |

| Power of Main Engine ( kw ) | 2.2 | 3 |

| Size ( mm ) | 2300*1250*1500 | 2550*1450*1650 |

| Voltage (V ) | 220 | 380 |

Charateritics:

1. This is a kind of flat-bed die cutting machine with high

precision, whose material-going is controlled by servo motor.

2. The three photoelectric eyes do the web guiding job.

3. Die cutting, laminating, waste rewinding an sheeter (or

rewinding) can be finished in one process.

4. The machine is applicable to die cut adhesive paper label,

Dacron film label and laser anti-false label.

5. It is an ideal auxiliary for flexo printer, silk-screen printer,

rotogravure printer and so on.

Optional Configurations:

1. Hot stamping

2. Punching

3. Laminating

4. Adding conveyor belt

5. Full-cut for die cutting

After-service:

1. Warranty for machine: 12months

2. After-service: A reply within 24 hours

3. A free training in our factory available before delivering

machines

Functional characteristics of Protective Film Die Cutting Machine:

That machine with press structure, the servo motor&drives,

Computer controlthe complete line from feeding, die-cutting, waste

draining, cutting and rolling. The material edge sides are followed

by the light-magic eye to position the full-automatic high accuracy

mold to slice the machine lengthways

Application:

self-adhesive trademark, terylene film trademark, radium anti-fake

trademark, is a optimal assembled equipment of trade printing

machine, flexo printing machine, continuos screen printing machine,

gravure printing machine, anti-fake trademark machine. This machine

is also used in electronic industry and adhesive products industry.