Kunshan Dapeng Precision Machinery Co.,Ltd |

|

Parameters of film roll slitter rewinder machine

| Model | DP-700E |

| Max Width of Raw materials: | 700mm |

| Main Engineer Power | 3.7kw |

| Speed | 0-100m/min |

| Unwinding Diameter | 800mm |

| Rewinding Diameter | 450mm |

| Precision | ±0.1mm |

| Power | 380v 50hz |

| Package | Wooden case |

| Slitting width | 3mm-20mm |

Features of film roll slitter rewinder machine

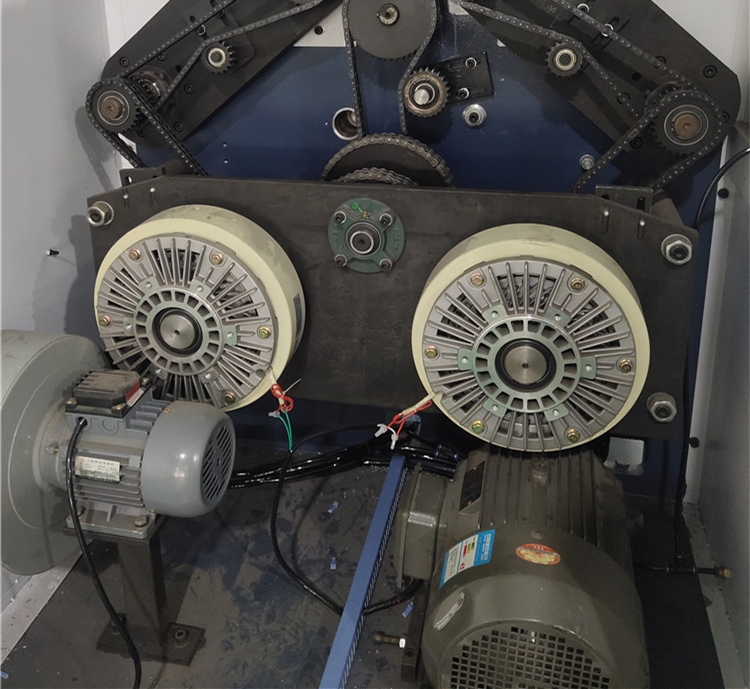

Main motor

Three motors,i.e.main motor and two rewind magnetic powder form constant control.

The main motor is for we feeding and rewind magnetic powder are for tension control,

so that the finished products have stable tension and beautiful outlook.

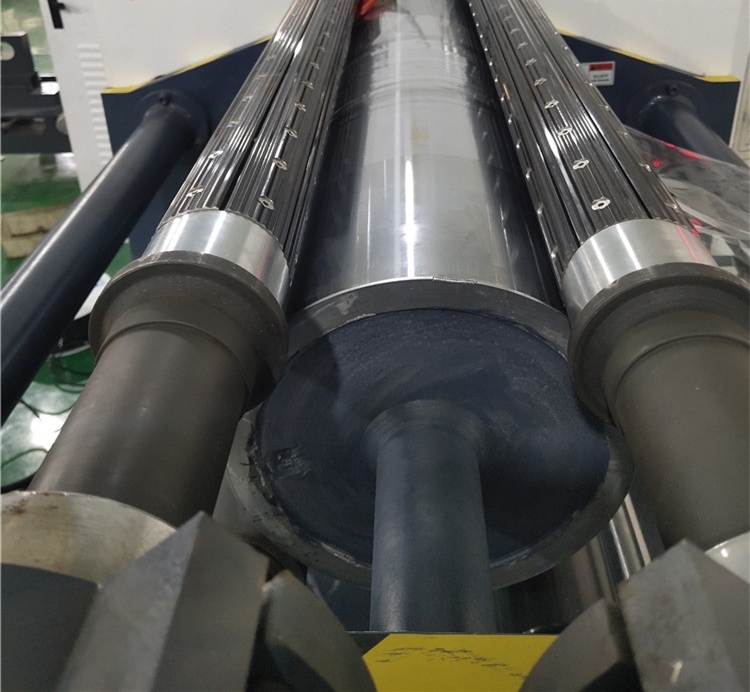

Rewind device

Rewind shaft arm adopts pneumatic type to control balance,

so that contact pressure is adjustable automatically.

This machine has optional discontinuous guide roll rewind for slitting many order materials.

Electric device

LCD touch panel is used for setting tension, length, etc.

The control system adopts PLC to control movements with self-detection function, so error can be found out easily.

Unwind device

Separate unwind base for bigger unwind diameter.

Parameters of slitting and rewinding machine

| Machine speed | 160m/min |

| Unwind diameter | 1000 mm |

| Rewind diameter | 600mm |

| Max width of material | 1300mm |

| Min slitting width | 10mm |

| Applicable material | PVC: 40-80µmm² PET Film: 12~60µm CPP Film: 30~60µm PE Film: 40-80µm Nylon Film: 20-50µm Paper: 30-80g/m²,etc |

Main Features of slitting and rewinding machine

1. Controlled by PLC system,human-machine interface.

2. LCD screen display, working status self-monitoring, meter counter.

3. Automatic Tension Control System and ultrasonic edge position controlling for unwinding.

4. Pneumatic shaft Clutch and Hydraulic Pressure Lift (optional) for Unwindling Roller Loading.

5. Centre surface rewinding.

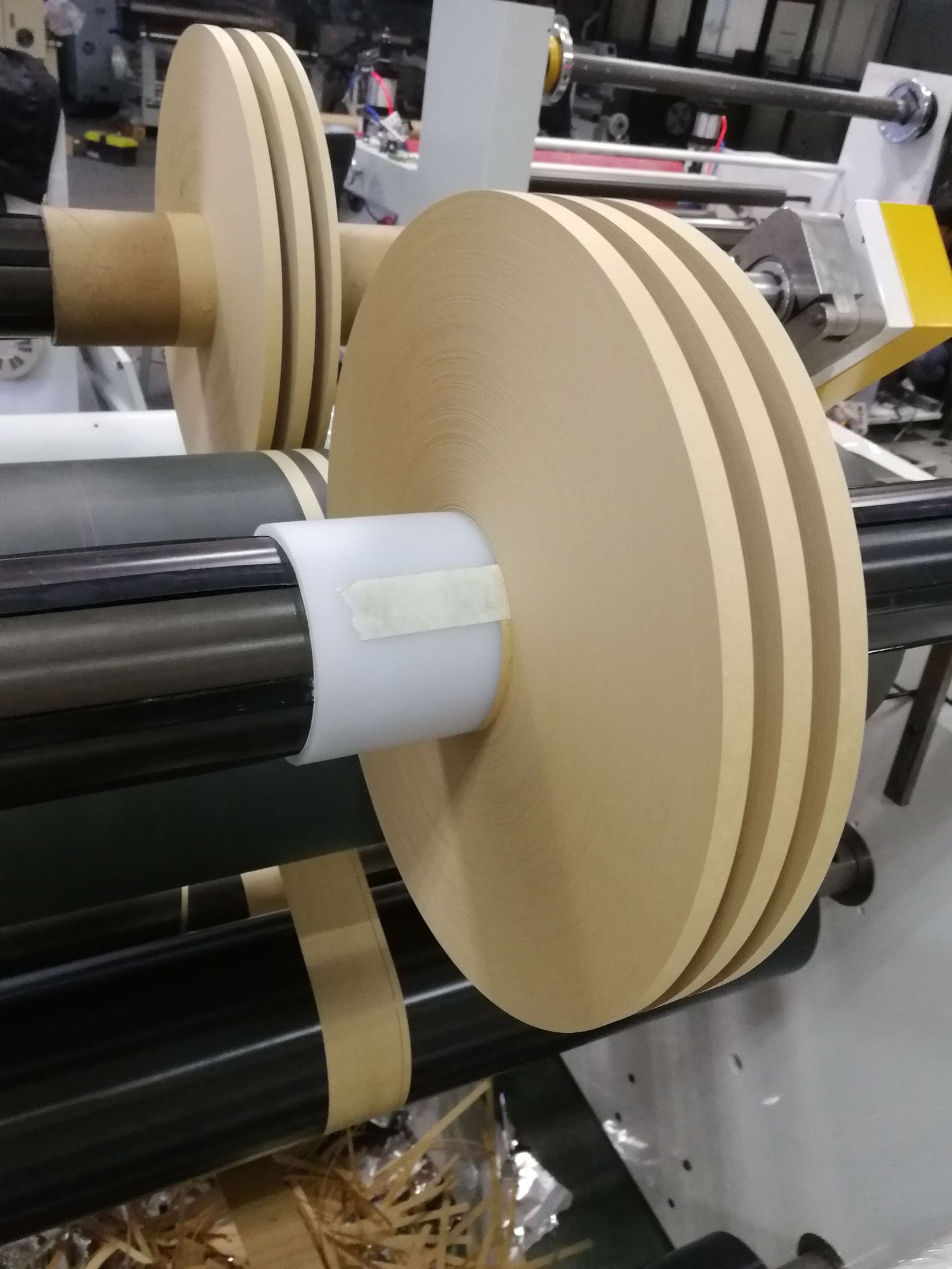

Application

Center surface slitting and rewinding machine.

Suitable for slitting industrial tapes, cellophane tape, protection film, copper foil,

aluminium foil, OPP, PP, PVC, paper, EVA, release paper, PI, etc.

It's widely used in printing, packaging, electronic, leather, garment-making & rubber, textile industries etc.

1. Q: Are you a factory or trading company?

A: We are a factory, professional manufacturer.

2. Q: Where is your factory located? How can I visit there?

A: Our factory is located in Kunshan City, Jiangsu Province, China,

near Shanghai.

You can fly to Shanghai Hongqiao airport directly.

All our clients are warmly welcome to visit us!

3. Q: Which industries are widely used in of your machine?

A: Those are mainly used in forming of three industries of adhesives products, electronics, and new energy power battery.

Examples of protective film, cutting backlight products, adhesive products, mobile phone accessories,

insulation film, garment accessories, automotive adhesives tapes etc.

4. Q: Could you send samples?

A: We are honored to receive your samples for Slitting Test.

5. Q: How does your factory do regarding quality control?

A: Quality is our culture.

We always attach great importance to quality controlling from the very beginning to the very end.

Our factory has gained ISO9001 authentication.

6. Q: How can I find the most appropriated machine for my material?

You can tell us the parameters of your material, then we can recommend you the most suitable machine for you.

Material Name:

Raw width of the material:

Thickness of the material:

Slitting width of the material:

Rewinding diameter:

Unwinding diamater:

Inner core diameter:

By the way, if you need videos of the machines, welcome to contact me.