Langfang Ouhang Technology Co., Ltd. |

|

| NO. | Size | De | Material | Class 600 | Weight | |||||

| In | mm | mm | S | L | B | Db | Type | KG | ||

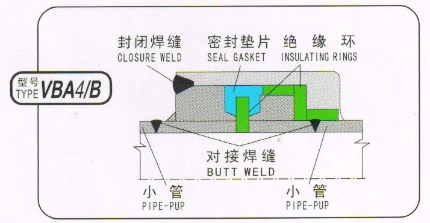

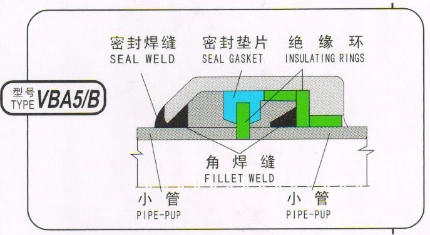

| 1 | 1/2 | 15 | 21.3 | GrB/L245 | 3.7 | 250 | 98 | 83 | 5/B | 6 |

| 2 | 3/4 | 20 | 26.7 | GrB/L245 | 3.9 | 250 | 94 | 85 | 5/B | 6 |

| 3 | 1/2 | 25 | 33.4 | GrB/L245 | 3.9 | 250 | 100 | 88 | 5/B | 6 |

| 4 | 1-1/4 | 32 | 42.4 | GrB/L245 | 3.9 | 300 | 100 | 91 | 5/B | 9 |

| 5 | 1-1/2 | 40 | 48.3 | GrB/L245 | 3.9 | 300 | 100 | 94 | 5/B | 9 |

| 6 | 2 | 50 | 60.3 | GrB/L245 | 3.9 | 350 | 104 | 114 | 5/B | 10 |

| 7 | 2-1/2 | 65 | 76.1 | GrB/L245 | 5.5 | 350 | 117 | 132 | 5/B | 15 |

| 8 | 3 | 80 | 88.9 | GrB/L245 | 5.5 | 500 | 123 | 155 | 5/B | 23 |

| 9 | 4 | 100 | 114.3 | GrB/L245 | 6 | 500 | 128 | 190 | 5/B | 34 |

| 10 | 5 | 125 | 141.3 | GrB/L245 | 6.5 | 600 | 148 | 217 | 5/B | 53 |

| 11 | 6 | 150 | 168.3 | X52/L360 | 7.1 | 600 | 161 | 248 | 5/B | 74 |

| 12 | 8 | 200 | 219.1 | X52/L360 | 8.2 | 600 | 183 | 297 | 5/B | 118 |

| 13 | 10 | 250 | 273 | X52/L360 | 9.3 | 800 | 211 | 368 | 7/B | 212 |

| 14 | 12 | 300 | 323.8 | X52/L360 | 9.5 | 800 | 232 | 440 | 7/B | 317 |

| 15 | 14 | 350 | 355.6 | X52/L360 | 12.7 | 1000 | 231 | 455 | 7/B | 380 |

| 16 | 16 | 400 | 406.4 | X60/L415 | 12.7 | 1000 | 280 | 540 | 7/B | 592 |

| 17 | 18 | 450 | 457.2 | X60/L415 | 14.3 | 1000 | 290 | 600 | 7/B | 755 |

| 18 | 20 | 500 | 508 | X60/L415 | 15.9 | 1200 | 308 | 684 | 4/B | 1057 |

| 19 | 22 | 550 | 558.8 | X60/L415 | 17.5 | 1200 | 342 | 730 | 4/B | 1325 |

| 20 | 24 | 600 | 609.6 | X60/L415 | 19 | 1200 | 388 | 810 | 4/B | 1795 |

| 21 | 26 | 650 | 660.4 | X60/L415 | 19 | 1200 | 400 | 845 | 4/B | 2003 |

| 22 | 28 | 700 | 711.2 | X60/L415 | 19 | 1300 | 405 | 890 | 4/B | 2265 |

| 23 | 30 | 750 | 762 | X60/L415 | 19 | 1300 | 421 | 970 | 4/B | 2733 |