Nodha Industrial Technology Wuxi Co., Ltd |

|

Nodha Brand Split Frame Pipe Cold Cutting Machine With Hydraulic Operated

The series machine is ideal for all types of pipe cutting, beveling and end preparation. The split frame design allows the machine to split in half at the frame and mount around the OD of the in-line pipe or fittings for strong, stable clamping. The equipment performs precision in-line cut or simultaneous cut/bevel, single point, counterbore and flange facing operations, as well as weld end preparation on open ended pipe, Ranging from 2” to 48” O.D.(DN50-1200), on most wall thicknesses and material.

| Features of Clamshell pipe cutter |

| Application of Clamshell pipe cutter |

| Specification of Clamshell pipe cutter |

| Selection Guide |

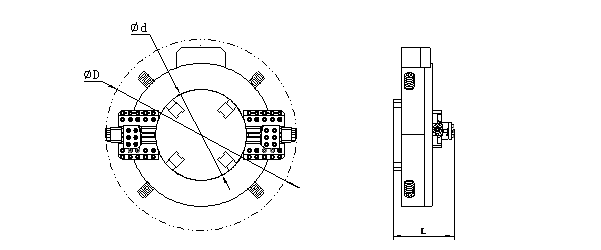

| Model | Working Range (OD) | d (mm) | D(mm) | L (mm) | |

| Inch | mm | ||||

| 168 | 2”-6” | 50-168 | 185 | 512 | 178 |

| 230 | 3”-8” | 80-230 | 236 | 564 | 178 |

| 275 | 5”-10” | 125-275 | 283 | 612 | 178 |

| 325 | 6”-12” | 168-325 | 334 | 665 | 178 |

| 377 | 8”-14” | 219-377 | 386 | 719 | 178 |

| 426 | 10”-16” | 273-426 | 438 | 776 | 180 |

| 457 | 12”-18” | 300-457 | 469 | 807 | 180 |

| 508 | 14”-20” | 355-508 | 518 | 862 | 190 |

| 560 | 16”-22” | 400-560 | 570 | 910 | 190 |

| 610 | 18”-24” | 457-610 | 618 | 960 | 190 |

| 660 | 20”-26” | 508-660 | 670 | 1020 | 190 |

| 715 | 22”-28” | 550-715 | 719 | 1084 | 190 |

| 762 | 24”-30” | 600-762 | 770 | 1134 | 190 |

| 830 | 26”-32” | 660-813 | 830 | 1194 | 192 |

| 914 | 30”-36” | 762-914 | 924 | 1296 | 212 |

| 1066 | 36”-42” | 914-1066 | 1077 | 1468 | 212 |

| 1230 | 42”-48” | 1066-1230 | 1248 | 1646 | 212 |

Suggest: size 1066 and above size select and use hydraulic type

| Order Guide |

Before you place order to us, please let us know the following information:

Choose suitable Model

Confirm electric power supply ( Voltage, frequency and phase)

Confirm the beveling angel needed

Confirm the welding joint required (U, V, Double V or Compound preparation)

If the pipe wall thickness more than 30mm, inform us in advance (Important)

Working On Site

Exhibition

Certification

After-Sale Service

1. Warranty period: 12 months

2. Emergency spare parts required dispatched within 24 hours