Boyee (Shenzhen) Industrial Technology Co., Ltd. |

|

Verified Suppliers

|

Centrifugal Bead Mill

The Boyee NMM series sand mill applies a single-power filter static discharge method to provide better grinding and dispersion effects of high-

viscosity materials, and handle products with a maximum viscosity of 100,000 CPS. Moreover, this product series applies two different nano-level

grinding systems, turbine and rod pin, and is equipped with patented TurboMax turbine structure that helps provide a gentler and finer grinding

effect and prevent excessive dispersion of materials. Moreover, its double-end mechanical seal and spiral-guided cooling circuit design contribute

to excellent operational stability and enhanced productivity by 50% with a reduced cost by 30%.

Centrifugal Bead Mill Parameter:

| Model | Cylinder volume (L) | Power (KW) | Disperser rotating speed (r/min) | Medium loading (%) | Size L*W*H(mm) | Weight (kg) |

| 30L | 30 | 45 | 0-1000 | 60-80 | 1800x1300x1800 | 2100 |

Centrifugal Bead Mill Machine Features:

The turbine, disc or pin-type inner structure of bead mill allows high grinding efficiency. It can reach 100 nanometers for D90;

According to the process characteristic, the rotation rate of the dispersion shaft can be changed by the frequency conversion technology

to get the best process parameters;

Pressure and temperature automatic control devices ensure safe production;

Reasonable design for inner and outer structure allows stable performance with no vibration and noise;

Ceramic and PU material is optional;

Frequency control and PLC are optional;

With CE&ISO9001:2008 qualification;

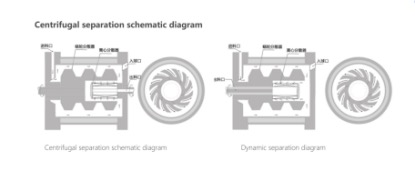

Dynamic or static separating system for different material to ensure smooth discharging.

Centrifugal Bead Mill Application:

Widely used in the industry of Silicon carbon anode, Carbon nanotube conductive paste,new energy, battery material etc.

Technological Indicators