Chuzhou Huihuang Nonwoven Technology Co., Ltd. |

|

Verified Suppliers

|

|

Automatic 3200 PP Meltblown Melt Blown Fabric production line melt blown non woven fabric making machine

About non woven die head

HHM-3200 Melt Blown line data

| Effective Width | 3200mm |

| Weight Range | 15-300 g / ㎡ |

| Out put day | 4.5 -5 ton |

| Machine speed | 10-70 m/ min |

| Transformer | ≈1000 KVA |

| Power consumption | 3000º - 3500º / ton |

| Machine Size | 18 *13 *10 M |

Description Melt blown machine raw material

| Raw materials | pp polypropylene | Melting point | 166℃ |

| Spunbond pp melt index | 28-45 | Denier of spunbond fiber | 1.8-2.5 denier |

| Meltblown pp melt index | 1300-1800 | Denier of melt blown fiber | 1.6-4 microns |

Technical Parameters

| Model | HHM-1.6m | HHM-2.4M | HHM-3.2M |

| Effective Width | 1.6 M | 2.4 M | 3.2 M |

| Weight Range | 18-300 G/㎡ | 18-300 G/㎡ | 18-300 G/㎡ |

| Out put day | 2-3 Ton | 3-4 Ton | 4.5-5 Ton |

| Machine Speed | ≦70 m/min | ≦70 m/min | ≦70 m/min |

| Power Consumption | 3000º-3500º/Ton | 3000º-3500º/Ton | 3000º-3500º/Ton |

| Machine Size(L*W*H) | 18M*10M*10M | 18M*11M*10M | 18M*13M*10M |

Meltblown Making Machine Series

| Model | Product Width (mm) | GSM Range ( g / ㎡ ) | Capacity (kg /day ) | Melt blown (BFE&PFE) |

| HHM- 1600 | 1600 | 15 - 300 | 200 - 300 | BFE 99+ PFE 95+ |

| HHM - 2400 | 2400 | 300 - 400 | ||

| HHM - 3200 | 3200 | 450 - 500 |

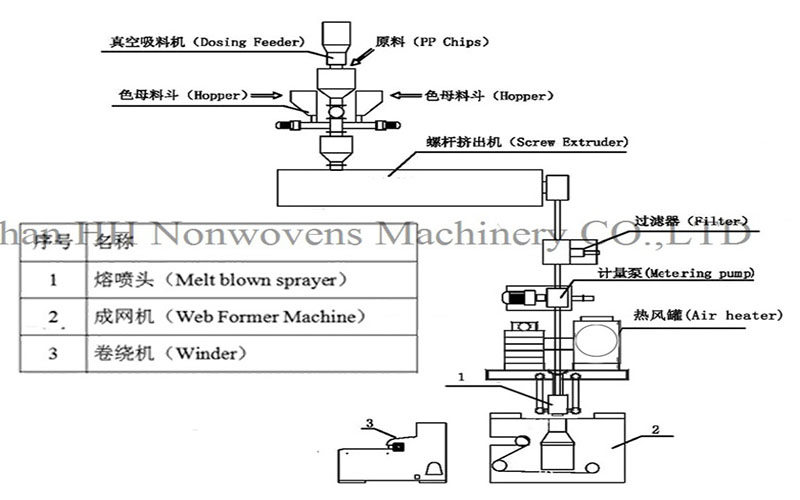

Meltblown non-woven fabric production line components:

Screw extruder---->filter---->metering pump---->heating system---->melt blown box (Kasen)---->netting machine---- >Rewind

(1) Receiving networked device:

Line speed: up to 50m/min

Meltblown receiving adjustment range: 200mm

Installation form: It can be moved horizontally, which is convenient for installation, debugging and maintenance

Driving rate: 1.1KW

(2) Suction net fan:

Power: 75KW,

4. Hot air heating system

(1) Atlas air compressor

Boost pressure: 0.7MPa

Power: 120KW~200KW

(2) Air heater

Heating power: 220KW-240KW

Material of tank and pipeline: stainless steel 304

Insulation form: stainless steel seal outside the insulation layer

5. Electret system.

6. Rack platform device:

Steel structure, easy to disassemble, firm and reliable, including stairs, etc.

7. Die head heating power: about 70kw

8. Electrical control box

High precisely CNC center

Exhibition Show

Packing & shipping

Main machine parts will be packed with wooden cases.Electrical parts will be packed with plastic and then packed into wooden cases.For the steel structure they will be packed in bulk into containers.

FAQ

1.Q : Are you a factory or trading company ?

A : We are established in 2009 , has been in onwoven industry for more than ten years .

2.Q: Do you have technical support?

A: yes , we will provide on-site installation service.

3 Q : How does your factory do regarding quality control ?

A: Quality is the most important principle . we always attach great importane to quality controlling from the very beginnging to the very end , our factory has passed CE and ISO certification .

4 Q :How long is you machine’s warrant period .

A : bascily one year warranty , long time service support .