Eternal Bliss Alloy Casting & Forging Co.,LTD. |

|

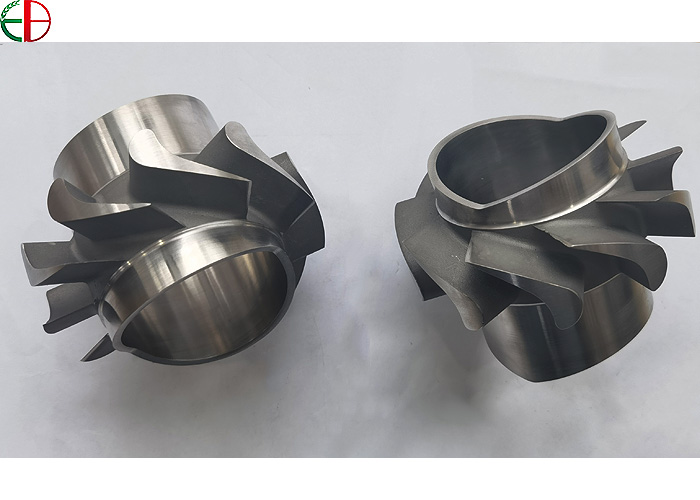

EB investment casting manufactured cobalt alloy Cobalt Based Alloy cobalt alloy alloy

![]()

1.Product Name: High quality investment casting | |

Material | Carbon steel, Alloy steel, Stainless steel, Aluminium,

Copper,Cobalt,Nickel etc |

Process | Lost wax casting + CNC machining |

Casting tolerance | ISO 2768-mK, VDG P690 D1-D2, ISO8062-3-2007 DCTG4-6, GCTG4-6 |

Casting roughness | Ra1.6-3.2 |

Machining roughness | Ra0.8-3.2 |

Casting weight range | 0.005-50kg |

Material standard | GB, ASTM, AISI, DIN, BS, JIS, NF, AS, AAR.... |

Surface treatment | Zinc plating, Polishing, Anodizing, Painting, Nickel plating |

Heat treatment | Annealing, Normalizing, Hardening, Tempering, Case hardening.... |

Service | OEM& ODM |

Quality Control | IATF16949:2016, ISO14001:2015, ISO9001 |

Application | as request |

C | Cr | Si | W | Fe | Mo | Ni | Mn | Co | |

Hardness | cobalt alloy 1 | 2.50 | 29.50 | 1.20 | 12.50 | 3.00 | 1.00 | 3.00 | 1.00 |

Bal. | 53.0 | cobalt alloy 3 | 2.40 | 31.00 | 1.00 | 12.50 | 3.00 | - | 3.00 |

1.00 | Bal. | 54.0 | cobalt alloy 4 | 0.90 | 32.00 | 1.00 | 13.50 | 1.00 | 0.50 |

0.50 | 0.50 | Bal. | 48.0 | 1.20 | 29.00 | 1.20 | 4.50 | 3.00 | |

1.00 | 3.00 | 1.00 | Bal. | 43.0 | cobalt alloy 12 | 1.45 | 29.00 | 2.00 | 8.50 |

3.00 | 1.00 | 3.00 | 1.00 | Bal. | 47.0 | cobalt alloy 20 | 2.45 | 32.50 | 1.00 |

17.00 | 3.00 | 1.00 | 3.00 | 0.50 | Bal. | 54.0 | cobalt alloy 21 | 0.25 | 27.00 |

1.00 | 0.15 | 2.00 | 5.50 | 2.50 | 1.00 | Bal. | 20.0 | cobalt alloy 31 | 0.50 |

25.50 | 1.00 | 0.15 | 2.00 | 5.50 | 2.50 | 1.00 | Bal. | 33.0 | cobalt alloy 190 |

3.20 | 26.00 | 1.00 | 14.00 | 5.00 | 1.00 | 3.00 | 1.00 | Bal. | 58.0 |

cobalt alloy 706 | 1.20 | 30.00 | 1.20 | - | 2.00 | 5.00 | 2.00 | 1.00 | Bal. |

42.0 | cobalt alloy 712 | 2.00 | 29.00 | 2.00 | 2.00 | 8.50 | 2.00 | 2.00 | |

Bal. | 50.0 | Tribaloy 400 | 0.08 | 8.50 | 2.60 | - | 1.50 | 28.50 | 1.50 |

- | Bal. | 53.0 | Tribaloy 800 | 0.08 | 18.00 | 3.40 | - | 1.50 | 28.50 |

Product Details: