Eternal Bliss Alloy Casting & Forging Co.,LTD. |

|

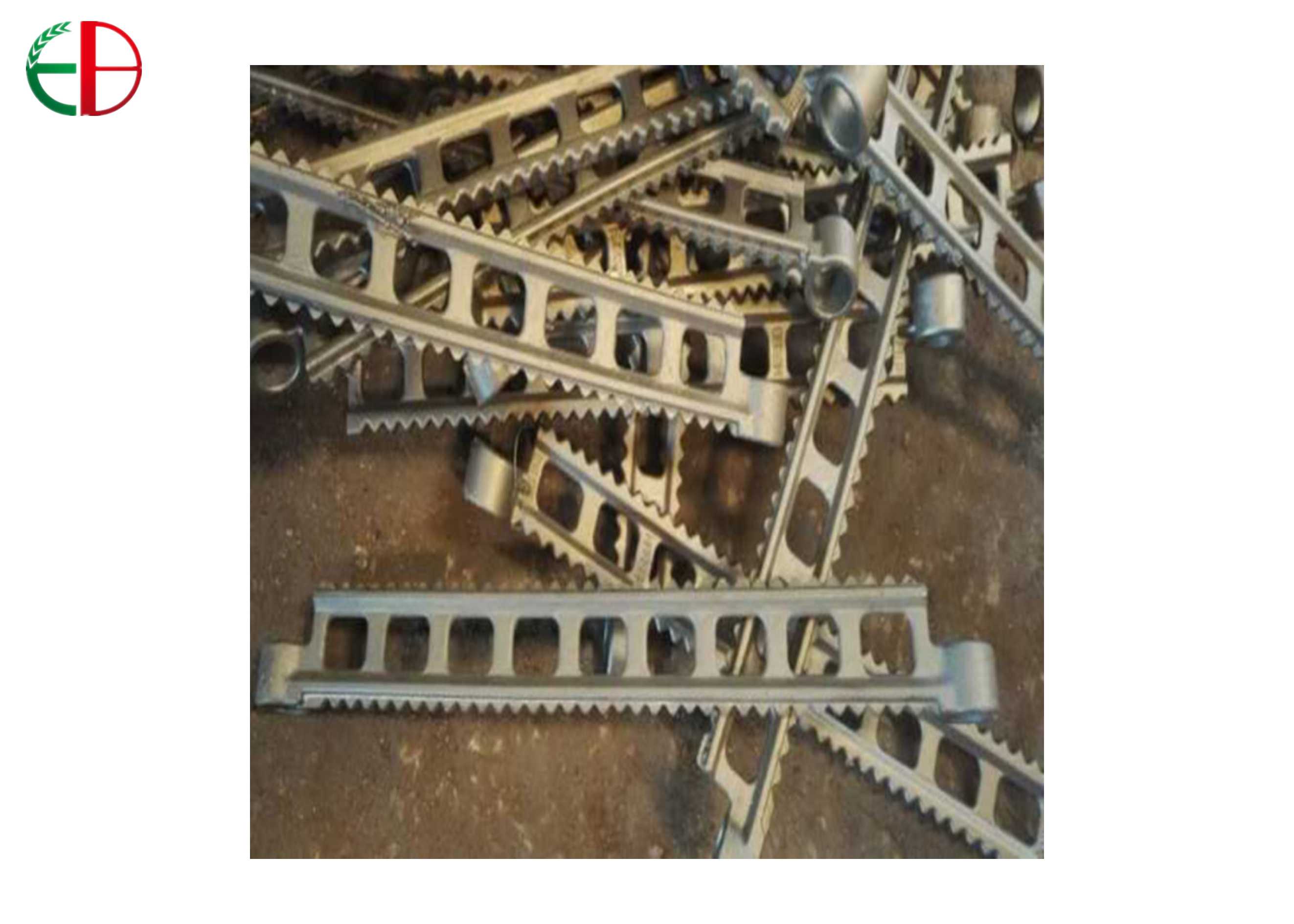

Material Grade: SCH23,ASTM A297 HL ,ASTM A297 HK ,Cr25Ni20,ZG40Cr25Ni20Si2,

Cr25Ni14; HK2Co20;1.4852;1.4849;Cr14Ni9;

Quality Level: As per National Standard & International Standards.

Production Process: Investment Process & Centrifugal Process & Sand

Process Including machining process.

Special Features:

1. We can make Rack with Investment Process & Centrifugal

Process & Sand Process.

2. We can supply finished Heat castings with heat-treatment and

machining process.

3. We can produce heat steel castings as per GB/T 20878,DIN

17440,DIN 17224, AISI,ASTM,JIS SUH35,NF

A35-572/584,BS970,BS1449,ISO 683/13.

Heat-resistant Steel-Chromiu

| JIS | ASTM AISI | Other's | Chemical Composition | ||||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | W | |||

| HA | ≦2.00 | ≦1.00 | 0.35~0.65 | ≦0.040 | ≦0.040 | - | 8.00~10.00 | 0.90~1.20 | - | ||

| SCH1 | - | 0.20~0.40 | 1.50~3.00 | ≦1.00 | ≦0.040 | ≦0.040 | MAX 1.00 | 12.00~15.00 | ≦ 0.50 | - | |

| SCH2 | HC | MAX 0.40 | ≦2.00 | ≦1.00 | ≦0.040 | ≦0.040 | MAX 1.00 | 25.00~28.00 | ≦0.50 | - | |

| SCH3 | - | MAX 0.40 | ≦2.00 | ≦1.00 | ≦0.040 | ≦0.040 | MAX 1.00 | 12.00~15.00 | ≦0.50 | - | |

| SCH11 | HD | MAX 0.40 | ≦2.00 | ≦1.00 | ≦0.040 | ≦0.040 | 4.00~6.00 | 24.00~28.00 | ≦0.50 | - | |

| SCH11G | 0.30~0.40 | ≦2.00 | ≦1.00 | ≦0.040 | ≦0.040 | 3.50~4.50 | 26.00~30.00 | 0.30~0.50 | - | ||

| SCH12 | HF | 0.20~0.40 | ≦2.00 | ≦2.00 | ≦0.040 | ≦0.040 | 8.00~12.00 | 18.00~23.00 | ≦0.50 | - | |

| SCH13 | HH | 0.20~0.50 | ≦2.00 | ≦2.00 | ≦0.040 | ≦0.040 | 11.00~14.00 | 24.00~28.00 | ≦0.50 | - | |

| SCH13A | HH2 | 0.25~0.50 | ≦1.75 | ≦2.50 | ≦0.040 | ≦0.040 | 12.00~14.00 | 23.00~26.00 | ≦0.50 | - | |

| SCH15 | HT | 0.35~0.70 | ≦2.50 | ≦2.00 | ≦0.040 | ≦0.040 | 33.00~37.00 | 15.00~19.00 | ≦0.50 | - | |

| SCH16 | HT30 | 0.20~0.35 | ≦2.50 | ≦2.00 | ≦0.040 | ≦0.040 | 33.00~37.00 | 13.00~17.00 | ≦0.50 | - | |

| SCH17 | HE | 0.20~0.50 | ≦2.00 | ≦2.00 | ≦0.040 | ≦0.040 | 8.00~11.00 | 26.00~30.00 | ≦0.50 | - | |

| SCH18 | HI | 0.20~0.50 | ≦2.00 | ≦2.00 | ≦0.040 | ≦0.040 | 14.00~18.00 | 26.00~30.00 | ≦0.50 | - | |

| SCH19 | HN | 0.20~0.50 | ≦2.00 | ≦2.00 | ≦0.040 | ≦0.040 | 23.00~27.00 | 19.00~23.00 | ≦0.50 | - | |

| SCH20 | HU | 0.35~0.75 | ≦2.50 | ≦2.00 | ≦0.040 | ≦0.040 | 37.00~41.00 | 17.00~21.00 | ≦0.50 | - | |

| HK | 0.20~0.60 | ≦2.00 | ≦2.00 | ≦0.040 | ≦0.040 | 18.00~22.00 | 24.00~28.00 | ≦0.50 | - | ||

| SCH21 | HK30 | 0.25~0.35 | ≦1.75 | ≦1.50 | ≦0.040 | ≦0.040 | 19.00~22.00 | 23.00~27.00 | ≦0.50 | - | |

| SCH22 | HK40 | 0.35~0.45 | ≦1.75 | ≦1.50 | ≦0.040 | ≦0.040 | 19.00~22.00 | 23.70~27.00 | ≦0.50 | - | |

| SCH22 | HK40 | 0.35~0.45 | ≦1.75 | ≦1.50 | ≦0.030 | ≦0.040 | 20.00~23.00 | 23.00~26.00 | ≦0.50 | - | |

| SCH23 | HL | 0.20~0.60 | ≦2.00 | ≦2.00 | ≦0.040 | ≦0.040 | 18.00~22.00 | 28.00~32.00 | ≦0.50 | - | |

| HL-30 | 0.25~0.35 | ≦2.00 | ≦1.50 | ≦0.040 | ≦0.040 | 18.00~22.00 | 28.00~32.00 | ≦0.50 | - | ||

| HL-40 | 0.35~0.45 | ≦2.00 | ≦1.50 | ≦0.040 | ≦0.040 | 18.00~22.00 | 28.00~32.00 | ≦0.50 | - | ||

| ISCH23 | 0.25~0.35 | 1.00-1.50 | 1.00-1.50 | 19.00~21.00 | 29.00~31.00 | - | 1.25-1.75 | ||||

| TH919 | 0.25~0.35 | ≦2.00 | ≦1.00 | 19.00~21.00 | 29.00~31.00 | - | 1.00-2.00 | ||||

| DCH27 | 0.34-0.45 | 29.00-31.00 | 33.00-35.00 | 4.00-6.00 | |||||||

| DCH25 | 0.25-0.35 | 28.00-32.00 | 24.00-26.00 | 1.50-2.50 | |||||||

| SCH24 | HP | 0.35~0.75 | ≦2.00 | ≦2.00 | ≦0.040 | ≦0.040 | 33.00~37.00 | 24.00~28.00 | ≦0.50 | - | |

| TH917 | 0.40~0.50 | ≦1.50 | ≦1.50 | 34.00~36.00 | 26.00~28.00 | - | 1.00-2.00 | ||||

| KHR35H | 0.37~0.47 | ≦1.50 | ≦1.50 | 34.00~37.00 | 24.00~28.00 | 1.00~1.50 | - | ||||

| HW | 0.35~0.75 | ≦2.50 | ≦2.00 | ≦0.040 | ≦0.040 | 58.00~62.00 | 10.00~14.00 | ≦0.50 | - | ||

| HX | 0.35~0.75 | ≦2.50 | ≦2.00 | ≦0.040 | ≦0.040 | 64.00~68.00 | 15.00~19.00 | ≦0.05 | - | ||

| MO-RE1 | 0.40~0.50 | 35.00~38.00 | 25.00~28.00 | MAX0.5 | 1.25-2.00 | ||||||

| MO-RE2 | 0.15~0.25 | 48.00~52.00 | 32.00~34.00 | MAX0.5 | 15.0-17.0 | ||||||

| Super22H | 0.40-0.60 | 46.00-50.00 | 26.00-30.00 | MAX0.5 | 4.00-6.00 | ||||||

| TAH37 | 0.30-0.50 | ≦2.00 | ≦2.00 | 31.00-35.00 | 26.00-30.00 | MAX0.5 | 1.00-2.00 | ||||

| NA22H | TAH32 | 0.40-0.60 | ≦2.00 | ≦2.00 | 45.00-50.00 | 25.00-29.00 | MAX0.5 | 4.00-6.00 | |||

| KHR48N | 0.40-0.60 | max1.50 | max1.50 | 45.00-50.00 | 25.00-30.00 | - | 4.00-6.00 | ||||

| HOM | TAH22 | 0.30-0.50 | ≦2.00 | ≦2.00 | 33.00-37.00 | 24.00-28.00 | 1.00-2.00 | - | |||

| KHRS2 | 0.35-0.45 | max2.0 | max2.0 | 22.00-25.00 | 24.00-27.00 | 1.80-2.30 | - | ||||

| KHRSA | 0.40-0.50 | max0.5 | 0.30-0.60 | 47.00-51.00 | 28.00-31.00 | - | 12.0-14.0 | ||||

| KHR40CM | MAX0.15 | 15.00-19.00 | 25.00-29.00 | 0.50-1.50 | - | ||||||

| KHR50CM | 0.05-0.12 | - | 26.00-30.00 | - | - | ||||||

| UMCO-50 | 0.05-0.12 | 0.5-1.0 | 0.5-1.0 | MAX0.02 | MAX0.02 | - | 27.00-29.00 | - | - | ||

| URM | TH502 | 0.10-0.20 | 40.0-42.0 | 32.0-34.0 | - | 0.3-0.6 | |||||

![]()

1. 18-year Foundry Operation Experience.

2. Friendly & High Efficient Technical & Commercial

Communication.

3. Professional Export Practices: Have Exported to +60 Overseas

Countries.

Our Trade Show

Our booth No. 14-A29-5 in Newcast 2015,Germany

Hall 14, Stand No.A29-5.

Contact Us for further information about products & service:

Mr.John Liu

Project Manager

Tel: 0086-188 0059 6372

Fax: 0086-510-6879 2172

E-mail: cast@ebcastings.com, ebcastings@163.com

Skype ID:julia.zhu26

QQ: 217 039 6403

www.ebcastings.com

Eternal Bliss Alloy Casting & Forging Co.,LTD.

Add.: J-Sci-Tech Park, Binhu District,Wuxi,214122, Jiangsu,China