Pneumatic Automatic Stacker System for Metal Roofing Machine

Stacking Sheet MachineWith a stacker, sheets are protected from scratches all the while

keeping your rollformer in production. The sheets stay

protected by sliding along the rollers and guides rather than each

other. The pneumatic powered stacker arms are triggered by a

photo eye which releases the panels and drops them onto the stacked

sheets. The design of both stackers allows for minimal drop

distance of the panel which is critical key to a successful

stacker. The drop distance is normally four inches. The less

distance the sheet has to drop, the more uniform the stacked sheets

will be.

Once an order is compete, the discharge table transfers the order

onto the C-frames for packaging, then returns back to the stacker

to allow the rollformer to stay running. The discharge table

is fully powered - in, out, up, down. This creates a higher

production rate and in turn, makes your company more profitable.

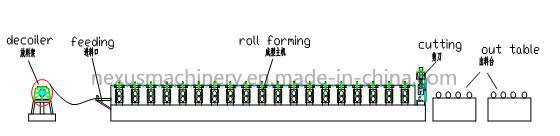

1. Processing flow diagram of Whole Production Line:

Decoiler→ Feeding →Roll forming →Measure length →Hydraulic

cutting →Output table(Automatic Stacker)

2. Technical parameters: | Pneumatic Automatic Stacker System for Metal Roofing Machine

Stacking Sheet Machine |

| Main motor power | 2.2kw |

| Drive | pneumatic |

| material | 45# forge steel and quenched |

| Length of stacker | 6m/8m/12m |

| Weight of stacker | About 5 ton |

| Size of stacker | About 10000×1800×2000mm L x W x H |

| Color of stacker | Yellow and Blue or Customized |

| No. | Product Name | QTY |

| 1 | Pneumatic Automatic Stacker System for Metal Roofing Machine

Stacking Sheet Machine | 1 |

1) Engineer will give free training lessons to labors in buyer's

factory.

2) The Buyer will buy the round-trip air ticket for Engineer if

visa application is approved. The buyer is also responsible to bear

expenses generated, e.g. visa formalities, meals, accommodation and

allowance of USD100 per day for engineer.

3) During this guarantee period, we will provide spare parts

without any charge in case of quality discrepancy caused by us. If

the malfunctions are caused by your incorrect operations, we will

provide the buyer spare parts at cost price.

4). We will charge the buyer cost price of spare parts beyond one

year and provide long-term technical guide.5. Photos of Pneumatic Automatic Stacker System for Metal Roofing

Machine Stacking Sheet Machine for Reference:

FAQ:

FAQ:

1. How long the machine could be made?- Normally speaking, stacker

machine could

be made within 45 working days. If you need machines in a hurry, we

can make it for you less than a month.

2. How to visit your company?

-a.Fly to Beijing airport: By high speed train From Beijing

Nan to Cangzhou Xi (1 hour),

then we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai

Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up

you.

3. Do you have after sales support?

-Yes, we are happy to give advice and we also have skilled

technicians available across the world.We need your machines

running in order to keep your business running.