Qingdao Magnet Magnetic Material Co., Ltd. |

|

30×13.5×3 N35-N54 NdFeB Magnet Sintered Magnet

Introduction of Sintered NdFeB Magnets

Sintered NdFeB magnets, namely sintered NdFeB magnets, are permanent magnet materials based on NdFeB tetragonal crystal structure. Sintered NdFeB magnets were invented by Mr. Sagawa's team in the early 1980s, and they are manufactured by a powder metallurgy process.

Sintered NdFeB magnets contain three basic elements, neodymium, iron and boron. Neodymium element can be replaced by a part of other rare earth elements including praseodymium, dysprosium, terbium, cerium, etc. The iron element can be replaced with part of the cobalt element to improve the Curie temperature Tc, thermal stability and corrosion resistance of the magnet. In order to control the microstructure and microchemistry to meet the desired properties, it also adds some doping elements, including aluminum, copper, niobium, gallium, etc. For customized sintered NdFeB magnets, controlling the formulation is the basic method to obtain the desired magnet grade.

Due to its excellent magnetic properties (high remanence Br 1.1-1.5 T, moderately high coercivity Hcj 800-3000 kA/m^3 and high maximum energy product (BH)max 220-430 kJ/m^3) and Competitive cost, sintered NdFeB magnets are widely used in DC motors, servo motors, stepper/stepper motors, synchronous motors, linear motors, voice coil motors (VCM), wind turbines and generators, magnetic resonance imaging (MRI) ), electric power steering (EPS), magnetic separation, etc.

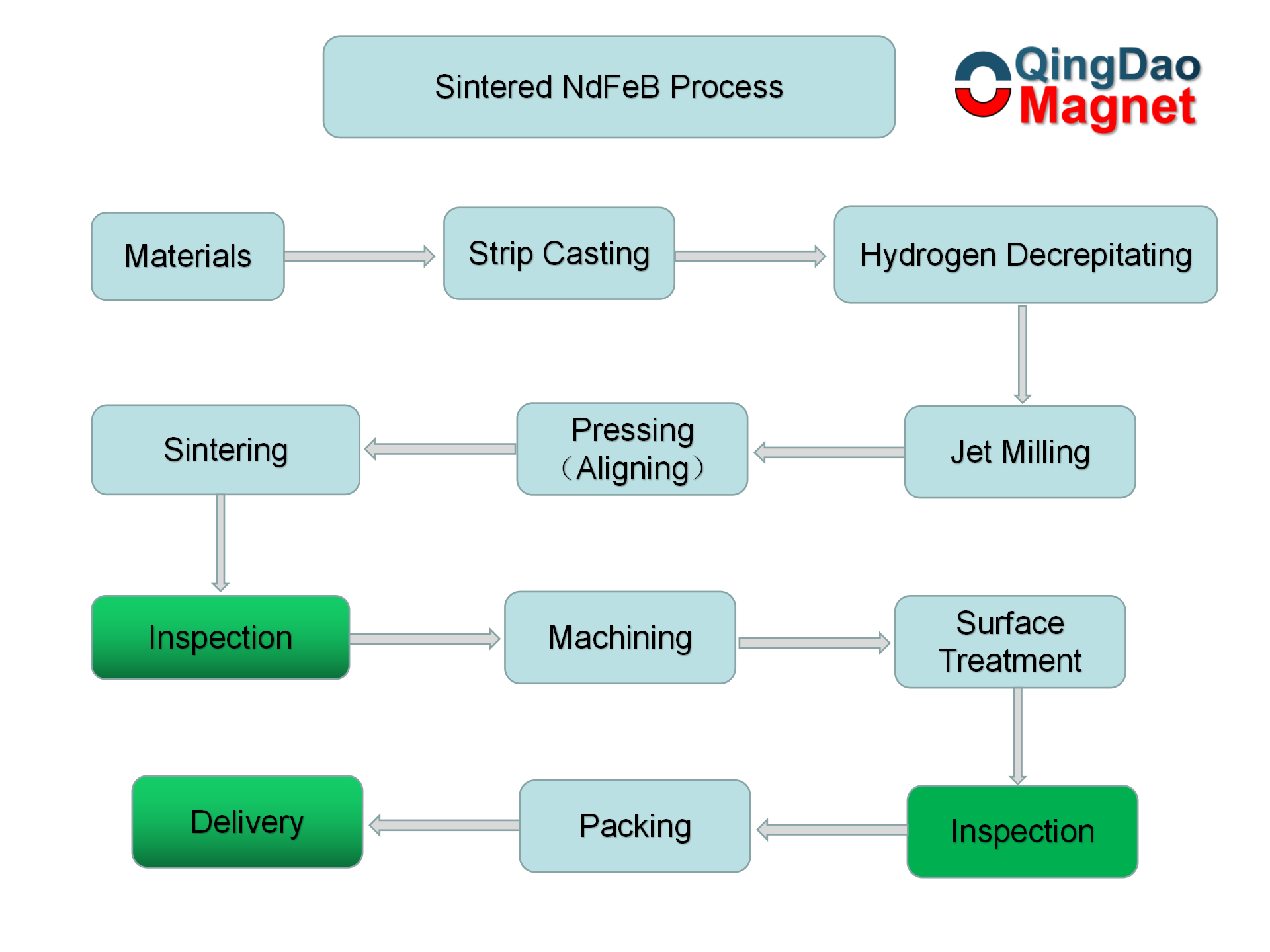

Magnetic Process

Magnetic Parameters

| QINGDAO MAGNET MAGNETIC MATERIAL CO.,LTD. Sintered NdFeB Magnet Performance Parameter | |||||||||||||

| Grade | Br(20℃) | Coercivity | BH(max)(20℃) | Temperature Coefficient | Density | Max.Working Temp. | ||||||||

| Br | Hcj | Hcb | BH(max) MGOe | T1-T2 | TK(Br) Reference | TK(Hcj) Reference | ρ Reference | Tmax Reference | ||||||

| T | KGs | kA/m | kOe | kA/m | kOe | kJ/m³ | MGOe | ℃ | %/℃ | %/℃ | g/cm³ | ℃ | ℉ | |

| N35 | 1.18-1.24 | 11.8-12.4 | ≥955 | ≥12 | ≥860 | ≥10.8 | 263-295 | 33-37 | 20-80 | -0.105 | -0.75 | 7.45 | 80 | 176 |

| N38 | 1.23-1.28 | 12.3-12.8 | ≥955 | ≥12 | ≥899 | ≥11.3 | 287-310 | 36-39 | 7.45 | 80 | 176 | |||

| N40 | 1.26-1.31 | 12.6-13.1 | ≥955 | ≥12 | ≥915 | ≥11.5 | 302-326 | 38-41 | 7.45 | 80 | 176 | |||

| N42 | 1.29-1.34 | 12.9-13.4 | ≥955 | ≥12 | ≥915 | ≥11.5 | 318-350 | 40-44 | 7.50 | 80 | 176 | |||

| N45 | 1.33-1.38 | 13.3-13.8 | ≥955 | ≥12 | ≥915 | ≥11.5 | 342-366 | 43-46 | 7.50 | 80 | 176 | |||

| N48 | 1.37-1.41 | 13.7-14.1 | ≥955 | ≥12 | ≥915 | ≥11.5 | 358-382 | 45-48 | 7.55 | 80 | 176 | |||

| N50 | 1.39-1.43 | 13.9-14.3 | ≥955 | ≥12 | ≥915 | ≥11.5 | 374-398 | 47-50 | 7.55 | 80 | 176 | |||

| N52 | 1.42-1.47 | 14.2-14.7 | ≥955 | ≥12 | ≥915 | ≥11.5 | 390-414 | 49-52 | 7.60 | 80 | 176 | |||

| N54 | 1.45-1.50 | 14.5-14.0 | ≥876 | ≥11 | ≥836 | ≥10.5 | 406-430 | 51-54 | 7.60 | 80 | 176 | |||

| 35M | 1.18-1.24 | 11.8-12.4 | ≥1114 | ≥14 | ≥868 | ≥10.9 | 263-295 | 33-37 | 20-100 | -0.105 | -0.70 | 7.45 | 100 | 212 |

| 38M | 1.23-1.28 | 12.3-12.8 | ≥1114 | ≥14 | ≥907 | ≥11.4 | 287-310 | 36-39 | 7.45 | 100 | 212 | |||

| 40M | 1.26-1.31 | 12.6-13.1 | ≥1114 | ≥14 | ≥931 | ≥11.7 | 302-326 | 38-41 | 7.50 | 100 | 212 | |||

| 42M | 1.29-1.34 | 12.9-13.4 | ≥1114 | ≥14 | ≥955 | ≥12.0 | 318-350 | 40-44 | 7.50 | 100 | 212 | |||

| 45M | 1.33-1.38 | 13.3-13.8 | ≥1114 | ≥14 | ≥987 | ≥12.4 | 342-366 | 43-46 | 7.55 | 100 | 212 | |||

| 48M | 1.37-1.41 | 13.7-14.1 | ≥1114 | ≥14 | ≥1019 | ≥12.8 | 358-382 | 45-48 | 7.55 | 100 | 212 | |||

| 50M | 1.39-1.43 | 13.9-14.3 | ≥1114 | ≥14 | ≥1035 | ≥13.0 | 374-398 | 47-50 | 7.60 | 100 | 212 | |||

| 52M | 1.42-1.47 | 14.2-14.7 | ≥1114 | ≥14 | ≥1059 | ≥13.3 | 390-414 | 49-52 | 7.60 | 100 | 212 | |||

| 54M* | 1.45-1.50 | 14.5-14.0 | ≥1114 | ≥14 | ≥1075 | ≥13.5 | 406-430 | 51-54 | 7.60 | 100 | 212 | |||

| 35H | 1.18-1.24 | 11.8-12.4 | ≥1353 | ≥17 | ≥876 | ≥11.0 | 263-295 | 33-37 | 20-120 | -0.105 | -0.60 | 7.45 | 120 | 248 |

| 38H | 1.23-1.28 | 12.3-12.8 | ≥1353 | ≥17 | ≥915 | ≥11.5 | 287-310 | 36-39 | 7.45 | 120 | 248 | |||

| 40H | 1.26-1.31 | 12.6-13.1 | ≥1353 | ≥17 | ≥939 | ≥11.8 | 302-326 | 38-41 | 7.50 | 120 | 248 | |||

| 42H | 1.29-1.34 | 12.9-13.4 | ≥1353 | ≥17 | ≥963 | ≥12.1 | 318-350 | 40-44 | 7.50 | 120 | 248 | |||

| 45H | 1.33-1.38 | 13.3-13.8 | ≥1353 | ≥17 | ≥995 | ≥12.5 | 342-366 | 43-46 | 7.55 | 120 | 248 | |||

| 48H | 1.37-1.41 | 13.7-14.1 | ≥1274 | ≥16 | ≥1027 | ≥12.9 | 358-382 | 45-48 | 7.55 | 120 | 248 | |||

| 50H | 1.39-1.43 | 13.9-14.3 | ≥1274 | ≥16 | ≥1043 | ≥13.1 | 374-398 | 47-50 | 7.60 | 120 | 248 | |||

| 52H* | 1.42-1.47 | 14.2-14.7 | ≥1274 | ≥16 | ≥1067 | ≥13.4 | 390-414 | 49-52 | 7.60 | 120 | 248 | |||

| 35SH | 1.18-1.24 | 11.8-12.4 | ≥1592 | ≥20 | ≥884 | ≥11.1 | 263-295 | 33-37 | 20-150 | -0.105 | -0.55 | 7.50 | 150 | 302 |

| 38SH | 1.23-1.28 | 12.3-12.8 | ≥1592 | ≥20 | ≥923 | ≥11.6 | 287-310 | 36-39 | 7.50 | 150 | 302 | |||

| 40SH | 1.26-1.31 | 12.6-13.1 | ≥1592 | ≥20 | ≥947 | ≥11.9 | 302-326 | 38-41 | 7.55 | 150 | 302 | |||

| 42SH | 1.29-1.34 | 12.9-13.4 | ≥1592 | ≥20 | ≥971 | ≥12.0 | 318-350 | 40-44 | 7.55 | 150 | 302 | |||

| 45SH | 1.33-1.38 | 13.3-13.8 | ≥1592 | ≥20 | ≥1003 | ≥12.6 | 342-366 | 43-46 | 7.60 | 150 | 302 | |||

| 48SH | 1.37-1.41 | 13.7-14.1 | ≥1592 | ≥20 | ≥1035 | ≥13.0 | 358-382 | 45-48 | 7.60 | 150 | 302 | |||

| 50SH | 1.39-1.43 | 13.9-14.3 | ≥1592 | ≥20 | ≥1051 | ≥13.2 | 374-398 | 47-50 | 7.60 | 150 | 302 | |||

| 52SH* | 1.42-1.47 | 14.2-14.7 | ≥1592 | ≥20 | ≥1075 | ≥13.3 | 390-414 | 49-52 | 7.60 | 150 | 302 | |||

| 30UH | 1.08-1.15 | 10.8-11.5 | ≥1990 | ≥25 | ≥812 | ≥10.2 | 223-255 | 28-32 | 20-180 | -0.115 | -0.45 | 7.55 | 180 | 356 |

| 33UH | 1.14-1.19 | 11.4-11.9 | ≥1990 | ≥25 | ≥860 | ≥10.8 | 247-271 | 31-34 | 7.55 | 180 | 356 | |||

| 35UH | 1.18-1.24 | 11.8-12.4 | ≥1990 | ≥25 | ≥892 | ≥11.2 | 263-295 | 33-37 | 7.55 | 180 | 356 | |||

| 38UH | 1.23-1.28 | 12.3-12.8 | ≥1990 | ≥25 | ≥931 | ≥11.7 | 287-310 | 36-39 | 7.60 | 180 | 356 | |||

| 40UH | 1.26-1.31 | 12.6-13.1 | ≥1990 | ≥25 | ≥955 | ≥12.0 | 302-326 | 38-41 | 7.60 | 180 | 356 | |||

| 42UH | 1.29-1.34 | 12.9-13.4 | ≥1990 | ≥25 | ≥979 | ≥12.3 | 318-350 | 40-44 | 7.60 | 180 | 356 | |||

| 45UH | 1.33-1.38 | 13.3-13.8 | ≥1990 | ≥25 | ≥1011 | ≥12.7 | 342-366 | 43-46 | 7.60 | 180 | 356 | |||

| 48UH* | 1.36-1.40 | 13.6-14.0 | ≥1990 | ≥25 | ≥1035 | ≥13.0 | 358-382 | 45-48 | 7.60 | 180 | 356 | |||

| 50UH* | 1.38-1.42 | 13.8-14.2 | ≥1990 | ≥25 | ≥1051 | ≥13.2 | 374-398 | 47-50 | 7.60 | 180 | 356 | |||

| 30EH | 1.08-1.15 | 10.8-11.5 | ≥2388 | ≥30 | ≥820 | ≥10.3 | 223-255 | 28-32 | 20-200 | -0.115 | -0.45 | 7.55 | 200 | 392 |

| 33EH | 1.14-1.19 | 11.4-11.9 | ≥2388 | ≥30 | ≥868 | ≥10.9 | 247-271 | 31-34 | 7.55 | 200 | 392 | |||

| 35EH | 1.18-1.24 | 11.8-12.4 | ≥2388 | ≥30 | ≥899 | ≥11.3 | 263-295 | 33-37 | 7.6 | 200 | 392 | |||

| 38EH | 1.22-1.26 | 12.2-12.6 | ≥2388 | ≥30 | ≥931 | ≥11.7 | 287-310 | 36-39 | 7.6 | 200 | 392 | |||

| 40EH | 1.25-1.29 | 12.6-13.1 | ≥2388 | ≥30 | ≥955 | ≥12.0 | 302-326 | 38-41 | 7.65 | 200 | 392 | |||

| 42EH* | 1.28-1.32 | 12.8-13.2 | ≥2388 | ≥30 | ≥979 | ≥12.3 | 318-350 | 40-44 | 7.65 | 200 | 392 | |||

| 45EH* | 1.32-1.37 | 13.2-13.7 | ≥2388 | ≥30 | ≥1011 | ≥12.7 | 342-366 | 43-46 | 7.65 | 200 | 392 | |||

| 48EH* | 1.36-1.40 | 13.6-14.0 | ≥2388 | ≥30 | ≥1035 | ≥13.0 | 358-382 | 45-48 | 7.65 | 200 | 392 | |||

| 30TH | 1.08-1.15 | 10.8-11.5 | ≥2786 | ≥35 | ≥820 | ≥10.3 | 223-255 | 28-32 | 20-250 | -0.115 | -0.40 | 7.6 | 250 | 482 |

| 33TH | 1.14-1.19 | 11.4-11.9 | ≥2786 | ≥35 | ≥868 | ≥10.9 | 247-271 | 31-34 | 7.6 | 250 | 482 | |||

| 35EH | 1.18-1.24 | 11.8-12.4 | ≥2786 | ≥35 | ≥899 | ≥11.3 | 263-295 | 33-37 | 7.65 | 250 | 482 | |||

| 38EH | 1.22-1.26 | 12.2-12.6 | ≥2786 | ≥35 | ≥931 | ≥11.7 | 287-310 | 36-39 | 7.65 | 250 | 482 | |||

| 40EH* | 1.25-1.29 | 12.6-13.1 | ≥2786 | ≥35 | ≥955 | ≥12.0 | 302-326 | 38-41 | 7.65 | 250 | 482 | |||

| Note: Grades with *marked apply special processes. | ||||||||||||||

Maximum operating temperature

Although the Curie temperature of NdFeB materials is around 310 ºC

for 0% cobalt and higher than 370 ºC for 5% cobalt, some

irreversible output loss may occur even at moderate temperatures.

The new magnets also have a moderately high reversible temperature

coefficient of induction, with the total magnetic output decreasing

with increasing temperature. The choice of neodymium magnets over

SmCo is a function of the maximum temperature of the application,

the desired magnetic output at typical operating temperatures, and

the total system cost.

The new magnet also has some limitations due to its corrosive behavior. In wet environments, a protective coating or electroplating is strongly recommended. Coatings that have been successfully applied include: electronic coatings, powder coatings, nickel plating, zinc plating, parylene, and combinations of these coatings.