Qingdao Magnet Magnetic Material Co., Ltd. |

|

D4.4×1.0 Computer Sintered NdFeB Magnets

Sintered NdFeB Magnets

Sintered NdFeB magnets are the most powerful magnets known. The maximum allowable temperature varies, but some grades are up to 240°C. This maximum temperature is important because the price of magnets increases with temperature.

Magnets consist of powder compacted in a magnetic field, so they have process fixed and limited magnetization directions. Usually the magnetic field lines must be parallel.

However, due to the low corrosion resistance of the material, corrosion protection of sintered neodymium magnets is always recommended. Corrosion resistance comparable to untreated pure iron. There are a range of different coatings(Nickel,Zinc,Epoxy, Parylene, Everlube,etc.) to choose from, but sometimes it is best to be completely encapsulated in stainless steel.

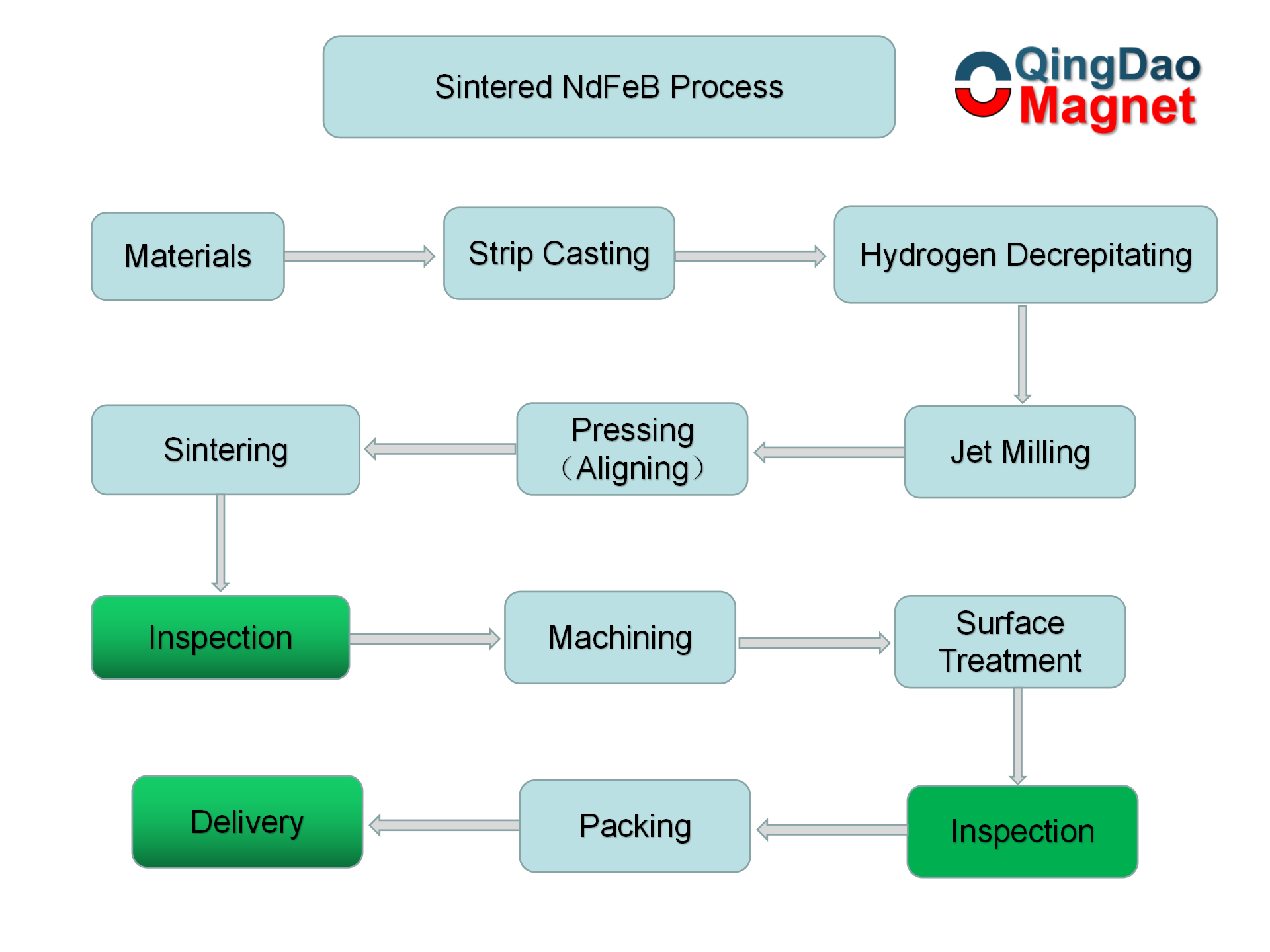

Magnetic Process

Magnetic Parameters

| QINGDAO MAGNET MAGNETIC MATERIAL CO.,LTD. Sintered NdFeB Magnet Performance Parameter | |||||||||||||

| Grade | Br(20℃) | Coercivity | BH(max)(20℃) | Temperature Coefficient | Density | Max.Working Temp. | ||||||||

| Br | Hcj | Hcb | BH(max) MGOe | T1-T2 | TK(Br) Reference | TK(Hcj) Reference | ρ Reference | Tmax Reference | ||||||

| T | KGs | kA/m | kOe | kA/m | kOe | kJ/m³ | MGOe | ℃ | %/℃ | %/℃ | g/cm³ | ℃ | ℉ | |

| N35 | 1.18-1.24 | 11.8-12.4 | ≥955 | ≥12 | ≥860 | ≥10.8 | 263-295 | 33-37 | 20-80 | -0.105 | -0.75 | 7.45 | 80 | 176 |

| N38 | 1.23-1.28 | 12.3-12.8 | ≥955 | ≥12 | ≥899 | ≥11.3 | 287-310 | 36-39 | 7.45 | 80 | 176 | |||

| N40 | 1.26-1.31 | 12.6-13.1 | ≥955 | ≥12 | ≥915 | ≥11.5 | 302-326 | 38-41 | 7.45 | 80 | 176 | |||

| N42 | 1.29-1.34 | 12.9-13.4 | ≥955 | ≥12 | ≥915 | ≥11.5 | 318-350 | 40-44 | 7.50 | 80 | 176 | |||

| N45 | 1.33-1.38 | 13.3-13.8 | ≥955 | ≥12 | ≥915 | ≥11.5 | 342-366 | 43-46 | 7.50 | 80 | 176 | |||

| N48 | 1.37-1.41 | 13.7-14.1 | ≥955 | ≥12 | ≥915 | ≥11.5 | 358-382 | 45-48 | 7.55 | 80 | 176 | |||

| N50 | 1.39-1.43 | 13.9-14.3 | ≥955 | ≥12 | ≥915 | ≥11.5 | 374-398 | 47-50 | 7.55 | 80 | 176 | |||

| N52 | 1.42-1.47 | 14.2-14.7 | ≥955 | ≥12 | ≥915 | ≥11.5 | 390-414 | 49-52 | 7.60 | 80 | 176 | |||

| N54 | 1.45-1.50 | 14.5-14.0 | ≥876 | ≥11 | ≥836 | ≥10.5 | 406-430 | 51-54 | 7.60 | 80 | 176 | |||

| 35M | 1.18-1.24 | 11.8-12.4 | ≥1114 | ≥14 | ≥868 | ≥10.9 | 263-295 | 33-37 | 20-100 | -0.105 | -0.70 | 7.45 | 100 | 212 |

| 38M | 1.23-1.28 | 12.3-12.8 | ≥1114 | ≥14 | ≥907 | ≥11.4 | 287-310 | 36-39 | 7.45 | 100 | 212 | |||

| 40M | 1.26-1.31 | 12.6-13.1 | ≥1114 | ≥14 | ≥931 | ≥11.7 | 302-326 | 38-41 | 7.50 | 100 | 212 | |||

| 42M | 1.29-1.34 | 12.9-13.4 | ≥1114 | ≥14 | ≥955 | ≥12.0 | 318-350 | 40-44 | 7.50 | 100 | 212 | |||

| 45M | 1.33-1.38 | 13.3-13.8 | ≥1114 | ≥14 | ≥987 | ≥12.4 | 342-366 | 43-46 | 7.55 | 100 | 212 | |||

| 48M | 1.37-1.41 | 13.7-14.1 | ≥1114 | ≥14 | ≥1019 | ≥12.8 | 358-382 | 45-48 | 7.55 | 100 | 212 | |||

| 50M | 1.39-1.43 | 13.9-14.3 | ≥1114 | ≥14 | ≥1035 | ≥13.0 | 374-398 | 47-50 | 7.60 | 100 | 212 | |||

| 52M | 1.42-1.47 | 14.2-14.7 | ≥1114 | ≥14 | ≥1059 | ≥13.3 | 390-414 | 49-52 | 7.60 | 100 | 212 | |||

| 54M* | 1.45-1.50 | 14.5-14.0 | ≥1114 | ≥14 | ≥1075 | ≥13.5 | 406-430 | 51-54 | 7.60 | 100 | 212 | |||

| 35H | 1.18-1.24 | 11.8-12.4 | ≥1353 | ≥17 | ≥876 | ≥11.0 | 263-295 | 33-37 | 20-120 | -0.105 | -0.60 | 7.45 | 120 | 248 |

| 38H | 1.23-1.28 | 12.3-12.8 | ≥1353 | ≥17 | ≥915 | ≥11.5 | 287-310 | 36-39 | 7.45 | 120 | 248 | |||

| 40H | 1.26-1.31 | 12.6-13.1 | ≥1353 | ≥17 | ≥939 | ≥11.8 | 302-326 | 38-41 | 7.50 | 120 | 248 | |||

| 42H | 1.29-1.34 | 12.9-13.4 | ≥1353 | ≥17 | ≥963 | ≥12.1 | 318-350 | 40-44 | 7.50 | 120 | 248 | |||

| 45H | 1.33-1.38 | 13.3-13.8 | ≥1353 | ≥17 | ≥995 | ≥12.5 | 342-366 | 43-46 | 7.55 | 120 | 248 | |||

| 48H | 1.37-1.41 | 13.7-14.1 | ≥1274 | ≥16 | ≥1027 | ≥12.9 | 358-382 | 45-48 | 7.55 | 120 | 248 | |||

| 50H | 1.39-1.43 | 13.9-14.3 | ≥1274 | ≥16 | ≥1043 | ≥13.1 | 374-398 | 47-50 | 7.60 | 120 | 248 | |||

| 52H* | 1.42-1.47 | 14.2-14.7 | ≥1274 | ≥16 | ≥1067 | ≥13.4 | 390-414 | 49-52 | 7.60 | 120 | 248 | |||

| 35SH | 1.18-1.24 | 11.8-12.4 | ≥1592 | ≥20 | ≥884 | ≥11.1 | 263-295 | 33-37 | 20-150 | -0.105 | -0.55 | 7.50 | 150 | 302 |

| 38SH | 1.23-1.28 | 12.3-12.8 | ≥1592 | ≥20 | ≥923 | ≥11.6 | 287-310 | 36-39 | 7.50 | 150 | 302 | |||

| 40SH | 1.26-1.31 | 12.6-13.1 | ≥1592 | ≥20 | ≥947 | ≥11.9 | 302-326 | 38-41 | 7.55 | 150 | 302 | |||

| 42SH | 1.29-1.34 | 12.9-13.4 | ≥1592 | ≥20 | ≥971 | ≥12.0 | 318-350 | 40-44 | 7.55 | 150 | 302 | |||

| 45SH | 1.33-1.38 | 13.3-13.8 | ≥1592 | ≥20 | ≥1003 | ≥12.6 | 342-366 | 43-46 | 7.60 | 150 | 302 | |||

| 48SH | 1.37-1.41 | 13.7-14.1 | ≥1592 | ≥20 | ≥1035 | ≥13.0 | 358-382 | 45-48 | 7.60 | 150 | 302 | |||

| 50SH | 1.39-1.43 | 13.9-14.3 | ≥1592 | ≥20 | ≥1051 | ≥13.2 | 374-398 | 47-50 | 7.60 | 150 | 302 | |||

| 52SH* | 1.42-1.47 | 14.2-14.7 | ≥1592 | ≥20 | ≥1075 | ≥13.3 | 390-414 | 49-52 | 7.60 | 150 | 302 | |||

| 30UH | 1.08-1.15 | 10.8-11.5 | ≥1990 | ≥25 | ≥812 | ≥10.2 | 223-255 | 28-32 | 20-180 | -0.115 | -0.45 | 7.55 | 180 | 356 |

| 33UH | 1.14-1.19 | 11.4-11.9 | ≥1990 | ≥25 | ≥860 | ≥10.8 | 247-271 | 31-34 | 7.55 | 180 | 356 | |||

| 35UH | 1.18-1.24 | 11.8-12.4 | ≥1990 | ≥25 | ≥892 | ≥11.2 | 263-295 | 33-37 | 7.55 | 180 | 356 | |||

| 38UH | 1.23-1.28 | 12.3-12.8 | ≥1990 | ≥25 | ≥931 | ≥11.7 | 287-310 | 36-39 | 7.60 | 180 | 356 | |||

| 40UH | 1.26-1.31 | 12.6-13.1 | ≥1990 | ≥25 | ≥955 | ≥12.0 | 302-326 | 38-41 | 7.60 | 180 | 356 | |||

| 42UH | 1.29-1.34 | 12.9-13.4 | ≥1990 | ≥25 | ≥979 | ≥12.3 | 318-350 | 40-44 | 7.60 | 180 | 356 | |||

| 45UH | 1.33-1.38 | 13.3-13.8 | ≥1990 | ≥25 | ≥1011 | ≥12.7 | 342-366 | 43-46 | 7.60 | 180 | 356 | |||

| 48UH* | 1.36-1.40 | 13.6-14.0 | ≥1990 | ≥25 | ≥1035 | ≥13.0 | 358-382 | 45-48 | 7.60 | 180 | 356 | |||

| 50UH* | 1.38-1.42 | 13.8-14.2 | ≥1990 | ≥25 | ≥1051 | ≥13.2 | 374-398 | 47-50 | 7.60 | 180 | 356 | |||

| 30EH | 1.08-1.15 | 10.8-11.5 | ≥2388 | ≥30 | ≥820 | ≥10.3 | 223-255 | 28-32 | 20-200 | -0.115 | -0.45 | 7.55 | 200 | 392 |

| 33EH | 1.14-1.19 | 11.4-11.9 | ≥2388 | ≥30 | ≥868 | ≥10.9 | 247-271 | 31-34 | 7.55 | 200 | 392 | |||

| 35EH | 1.18-1.24 | 11.8-12.4 | ≥2388 | ≥30 | ≥899 | ≥11.3 | 263-295 | 33-37 | 7.6 | 200 | 392 | |||

| 38EH | 1.22-1.26 | 12.2-12.6 | ≥2388 | ≥30 | ≥931 | ≥11.7 | 287-310 | 36-39 | 7.6 | 200 | 392 | |||

| 40EH | 1.25-1.29 | 12.6-13.1 | ≥2388 | ≥30 | ≥955 | ≥12.0 | 302-326 | 38-41 | 7.65 | 200 | 392 | |||

| 42EH* | 1.28-1.32 | 12.8-13.2 | ≥2388 | ≥30 | ≥979 | ≥12.3 | 318-350 | 40-44 | 7.65 | 200 | 392 | |||

| 45EH* | 1.32-1.37 | 13.2-13.7 | ≥2388 | ≥30 | ≥1011 | ≥12.7 | 342-366 | 43-46 | 7.65 | 200 | 392 | |||

| 48EH* | 1.36-1.40 | 13.6-14.0 | ≥2388 | ≥30 | ≥1035 | ≥13.0 | 358-382 | 45-48 | 7.65 | 200 | 392 | |||

| 30TH | 1.08-1.15 | 10.8-11.5 | ≥2786 | ≥35 | ≥820 | ≥10.3 | 223-255 | 28-32 | 20-250 | -0.115 | -0.40 | 7.6 | 250 | 482 |

| 33TH | 1.14-1.19 | 11.4-11.9 | ≥2786 | ≥35 | ≥868 | ≥10.9 | 247-271 | 31-34 | 7.6 | 250 | 482 | |||

| 35EH | 1.18-1.24 | 11.8-12.4 | ≥2786 | ≥35 | ≥899 | ≥11.3 | 263-295 | 33-37 | 7.65 | 250 | 482 | |||

| 38EH | 1.22-1.26 | 12.2-12.6 | ≥2786 | ≥35 | ≥931 | ≥11.7 | 287-310 | 36-39 | 7.65 | 250 | 482 | |||

| 40EH* | 1.25-1.29 | 12.6-13.1 | ≥2786 | ≥35 | ≥955 | ≥12.0 | 302-326 | 38-41 | 7.65 | 250 | 482 | |||

| Note: Grades with *marked apply special processes. | ||||||||||||||

The advantages of sintered neodymium magnets are:

The highest magnet strength available

High resistance to demagnetization

Operating temperature up to 240°C

Good at low temperature resistance. (down to – 100°C)

Possibility of more coils

Reduce waste - especially with complex geometries

Maximum operating temperature

Although the Curie temperature of NdFeB materials is around 310 ºC

for 0% cobalt and higher than 370 ºC for 5% cobalt, some

irreversible output loss may occur even at moderate temperatures.

The new magnets also have a moderately high reversible temperature

coefficient of induction, with the total magnetic output decreasing

with increasing temperature. The choice of neodymium magnets over

SmCo is a function of the maximum temperature of the application,

the desired magnetic output at typical operating temperatures, and

the total system cost.

The new magnet also has some limitations due to its corrosive behavior. In wet environments, a protective coating or electroplating is strongly recommended. Coatings that have been successfully applied include: electronic coatings, powder coatings, nickel plating, zinc plating, parylene, and combinations of these coatings.