SMT Intelligent Device Manufacturing (Zhejiang) Co., Ltd. |

|

Verified Suppliers

|

|

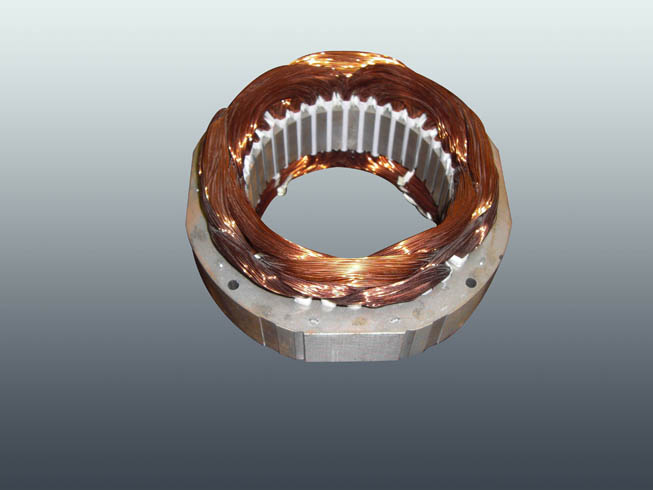

Generator Stator Coil Forming Machine / Automatic Stator Forming Machine

The machine is suitable for forming up the small to medium size stator coil; the operator put the on left side roller to form up inner side of coil, then put the stator on right side formiug mould to finally form up height, inner and outer side of coil to eusure the end product to meet the required specification.

(1) Main Technical Date

| Model | ZZ190 |

| Stator I.D. | 50-131mm |

| Stator O.D. | ≤191mm |

| Stack Height | 20-160mm |

| Displacement of cylinder | 20F |

| MOQ | 1 Coil Forming Machine |

| Power Supply | 380V/50/60Hz Kw |

| Weight | 1500kgs |

| Machine dimension | (L)1950*(W)1100*(H)2500mm |

(2) Application

The products are mainly applied in new energy automobile motor, servo motor, generator, three-phase motor, pump motor, compressor motor, household appliance motor and other induction motors. As a world leader, we have obvious advantages in stator and rotor core assembly, slot insulation, auto winding, auto inserting, auto fusing, auto resin impregnation and other motor production technology for different sizes and slot shape of stator.

(3) Machine Main Characteristic

This machine adopts whole hydraulic system and PCL program.

This machine can adjust the forming stack length by changing washer.

Both slot paper and wedge should not be damaged or turned over. The stator should not be deformation or stator lamination should not be upward. There is no wire enamel broken.

Production capacity ≤13s/set (exclude loading/unloading time)

Primary qualification rate ≥99.5%, after rework, the rate ≥99.9%

This machine adopts safety grating protection system. Operator need to stand when operating.

Machine adopts two hands simultaneously start button to ensure safety.

Efficiency stator coil forming machine,stator coil forming machine,coil forming machine work,coil forming machine used

(4) OEM/ODM

Innovational technical team provides perfect complete technical

solutions, to satisfy every customer’s unique requirement;

Specialized after-sale team and engineers offer superior quality,

rapid after-sale service door to door, to solve customer’s all

after-sale problems;

Wide spreaded domestic after-sale service service network stations

and overseas agencies ensure of powerful after-sale service;