Shaanxi Peakrise Metal Co.,Ltd |

|

Verified Suppliers

|

|

Utilizing Plate Molybdenum Electrodes in Fiberglass Kilns

1. Description of Plate Molybdenum Electrode Be Used For Fiberglass Kiln:

The high density (10.1 g/cm2) and high strength of the plate-shaped molybdenum electrode enable it to withstand the erosion and corrosion of high temperature glass liquid. Commonly used electric heating element materials are: silicon carbon rod, tin oxide, graphite, molybdenum and platinum. Among them, the melting point of molybdenum is as high as 2620±10℃, which has excellent electrical conductivity at high temperature, low thermal expansion coefficient, and is very stable in the reduction state, but it is easy to be oxidized at high temperature. Sintered molybdenum is brittle and difficult to cold work.

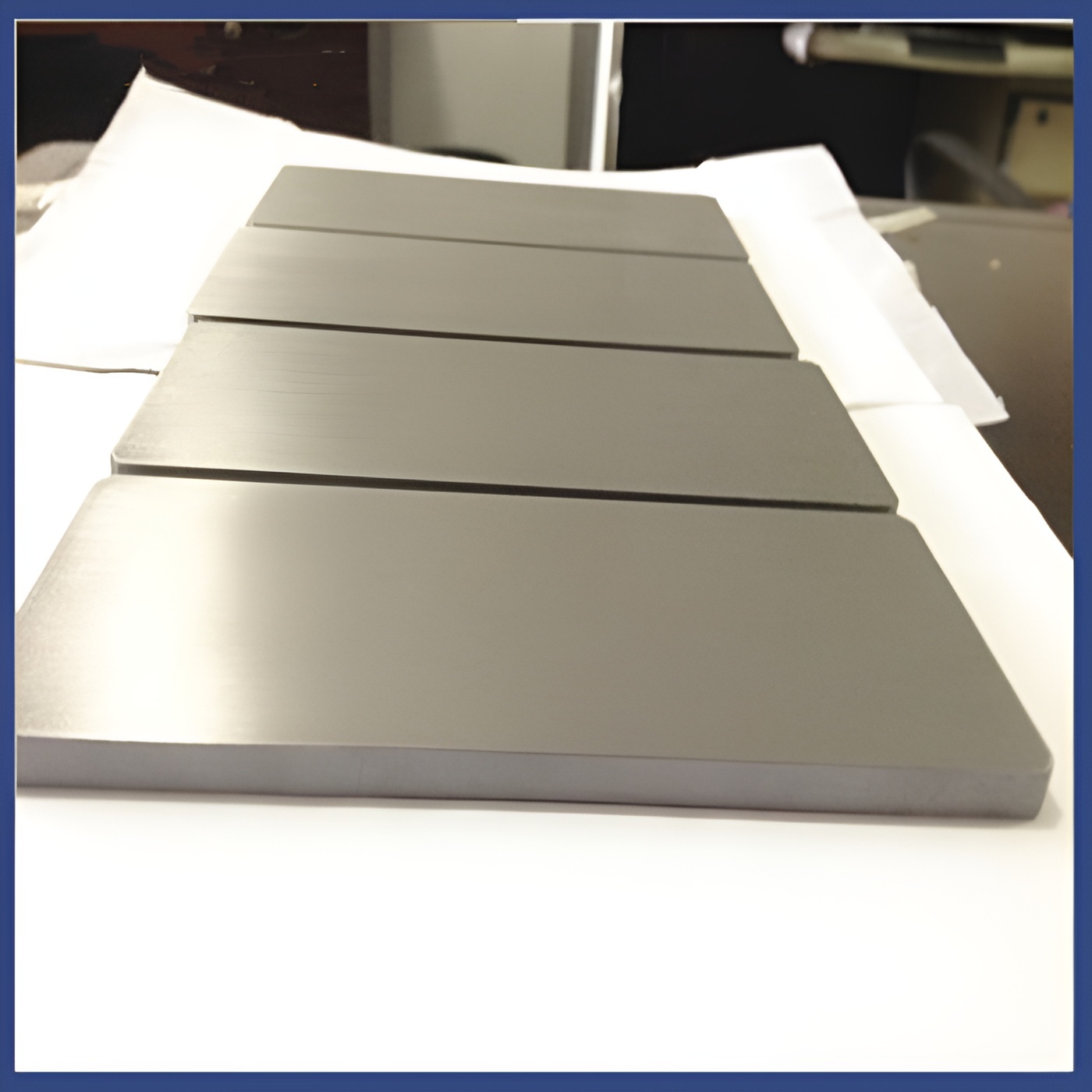

Molybdenum electrode rod The unit weight should not exceed 80kgs, molybdenum electrode rod 70kgs, molybdenum electrode plate 40kgs. Its appearance is bright silver-gray metallic luster, and they can be made according to customer's drawings.

2. Size of Plate Molybdenum Electrode Be Used For Fiberglass Kiln:

| Purity | Mo>99.95% | ||||||||

| Density | >10.2g/cm3 | ||||||||

| Size | (3 - 25)* (50 -500) *L<800mm | ||||||||

| Grade | Impurity content conforms to ASTM B386 standard | ||||||||

| Fe | Ni | Si | N | C | O | Mo | |||

| 361 | 0.01 | 0.005 | 0.01 | 0.002 | 0.01 | 0.007 | Remain | ||

3. Different applications of molybdenum electrode rods and molybdenum electrode plates:

Molybdenum electrode rods are widely used as furnace electrodes for electric booster glass furnaces.

The molybdenum electrode plate is dark brown with gray metallic luster such as silver alkali wash. Molybdenum electrode plates can be used as heating equipment for various glass fiber kilns, liquid flow orifice panels, etc.

4. Factors Influencing the Service Life of Plate Molybdenum Electrodes For Fiberglass Kiln:

The service life of the plate-shaped molybdenum electrode in the feed channel generally depends on the current density of the electrode, the flow rate and viscosity of the glass liquid, and the chemical composition of the glass. The greater the current density, the greater the flow rate of the glass liquid, the smaller the viscosity, and the shorter the electrode life. In order to make the aluminum electrode have a longer life, the following chemical components must be specified as follows: As2O3<0.1, Sb2O3<0.4, Fe2O3<1.5, CuO<0.5%, Cr2O3, MnO, F<1%.

When heating with molybdenum electrodes, sometimes small bubbles are found in the glass, which may come from two reasons:

The current density on the surface of the plate-shaped molybdenum electrode is too large;

The composition of the frit side exceeds the above specification.

When the glass furnace is discharged, foaming can be seen on the surface of the aluminum plate when the molybdenum electrode is taken out, which is mainly caused by the evaporation of MoO3.