Gu an Jianneng Trading Co., Ltd |

|

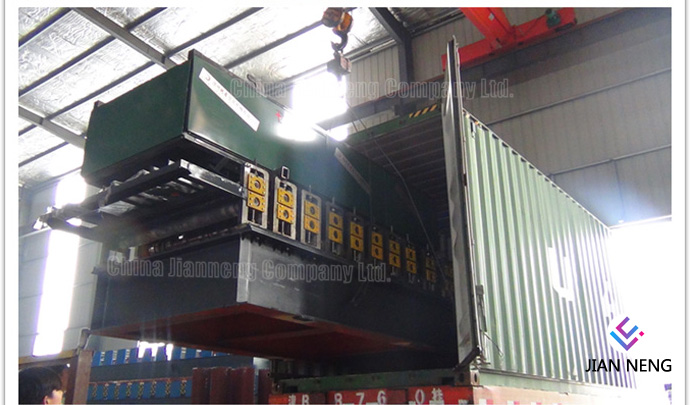

Hydraulic Steel Corrugated Roofing Sheet Crimping Machine , Metal Roofing Roll Forming Machine

Description :

Roof curving crimping machine Steel Crimping Machine Curved Roofing Sheet Machine hydraulic curving machine roof curving machine is also the nickname of the following name. This type roofing sheet crimping machine has two types: one is for motor type and the other is hydraulic type

Glazed tile, Roof Tile, Metal roof tile; steel roof tile; color steel tile; color glazed tile; wave tile; steel roofing sheet; metal roof panel; steel roof panel; roof wall cladding; roof cladding; wall cladding

Work Flowing:

Decoiler --- Fedding Guide --- Film Covering --- Roll Forming --- Pressing --- Cut-to-length --- Run out table

Application:

This roof panel used as the roofing of factory, warehouse. It is easy to realize the reliable and safety installation.

Specification / Technical Parameter

| No. | Main parameter of Metal Roof Sheet Roll Forming Machine | |

| 1 | Suitable to process | Color steel plate |

| 2 | Width of the plate | 1200mm |

| 3 | Rollers | 14 rows |

| 4 | Dimensions | 7100*1550*1510mm |

| 5 | Power | 4+4kw |

| 6 | Rolling material | 45# steel(plated chrome on surface) |

| 6 | Thickness of the plate | 0.3-0.6mm |

| 7 | Productivity | 8-10m/min |

| 8 | Diameter of the roller | Φ70mm |

| 9 | Voltage | 380V 50Hz 3phases |

| 10 | Material of the cutting plate | Cr12 |

| 11 | Hydraulic | 40# |

| 12 | Processing precision | Within 1.00mm |

| 13 | Control system | PLC control |

Feature & Advantages:

Hydraulic Steel Corrugated Roofing Sheet Crimping Machine , Metal Roofing Roll Forming Machine

1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome .to protect surface shiniing and strong

2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation.and hardness 60 degree.

3. Cutter blade: Cr12 mould steel with quenched treatment, long life time.

4. High precision: shafts for rollers are tooled by grinding machine. Rollers are CNC processed to ensure precision performance.

5 .automatic PLC : introduced Mitsubishi PLC with touch screen ,inverter,transformer.

6. powerful driving system: big inch train,or gear box driving system.

6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines.