Suzhou Makeit Technology Co.,Ltd. |

|

Verified Suppliers

|

|

1. Introduce

There healthy, comfortable and secure products are made with an artful and scientific attitude, using purely natural green materials as a basis of security, supported with safe and environment-friendly production technologies, enabling consumers to experience the softness of cotton, the comforts of silk, and the care as taken with babies. As one should return to its true natural, returning to the natural after disposed of.

Dissolve cellulose in the solvent of NMMO/ water to make a cellulose solution. After filtration and deforming, fibers are spun with dry-jet wet spinning method, and coagulated in water bath or dilute NMMO solution at a low temperature. Then, the prepared fibers are processed by stretching, water washing, cutting, applying oil and drying.

2. Specification

| Name | Lyocell Staple Fiber |

| Specification | 1.2D*38MM |

| Material | 100% Lyocell |

| Origin | China |

| Application | High-end fashion, underwear, jean, home textiles, medical products, facial masks, baby products and special paper etc. |

3. Application

| Dyeing technology |

Medium-temperature reactive dyes, with Remazol dyes the most suitable for dyeing.

|

Spinning technology |

It helps fibers have a better cohesive effect and a higher spinnability if a reasonable amount of grinding agent is added in the process of spinning. Mind that the quantity should be carefully decided, the drawing force be small, the speed of machine be slow so as to prevent fibers from being tangled up into a untidy mass in the processes of re- combing and spinning. Yarn-steaming temperature is below 90°C, and the duration is shorter than 20min.

|

| Apparel filed | Fashion, jean, leisure dresses, underwear etc. |

| Industrial filed |

Medicines and health, cleaning industry, tobacco industry, packing material etc.

|

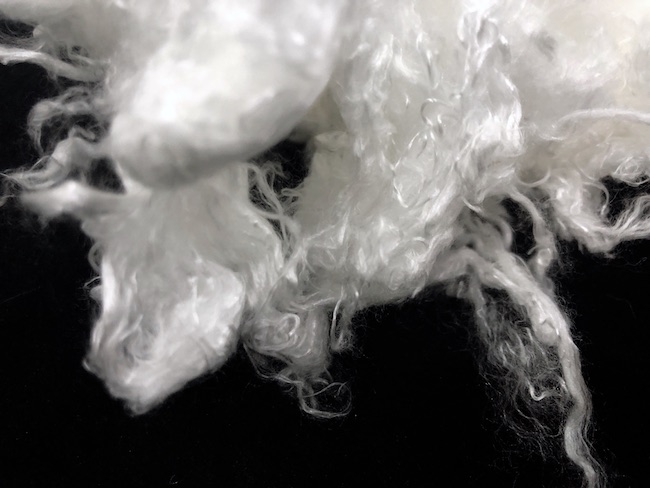

4. More pictures

5. Tips

Q: Where is the advantage of new solvent method-enabled regenerated cellulose fibers in performance over viscose fibers manifested?

A: By making preparations with the new solvent method, over 99% of NMMO solvent can be recovered, refined and reused, enabling the entire production system to form a closed recycling system, without the discharge of any harmful substance or waste, achieving the clean production regenerated cellulose fibers. These fibers combine the comforts and permeability of nature fibers with strength and enduring quality in chemical fibers, applicable to a wide range of fields, a fiber of new materials in trend in the 21st century when environmental protection and high quality is required.