Suzhou Makeit Technology Co.,Ltd. |

|

Verified Suppliers

|

|

1 . Introduce

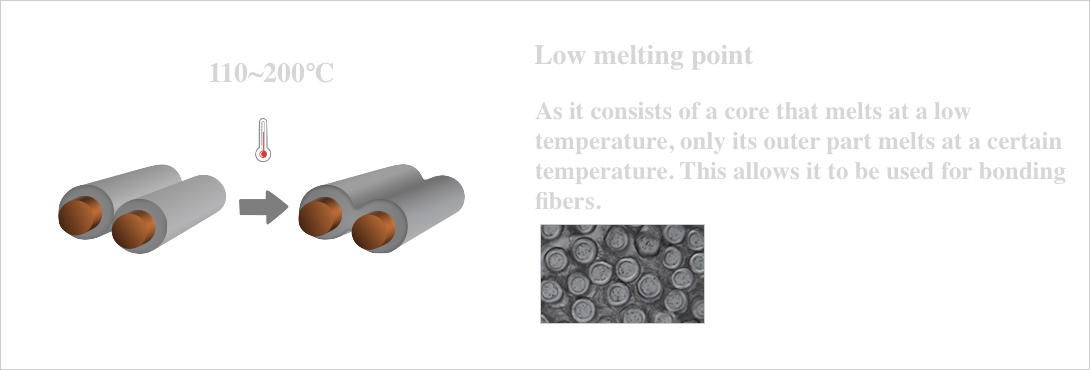

Made through conjugate spinning of general polyester and modified low-melting polyester, this material is used for adhesion as its low melting components are melted and adhered through heat processing. It is eco-friendly as it adheres at a low temperature (approximately 110℃) and boasts excellent ability to maintain a certain form after combining with other materials.

Low Melting Point Polyester (LMPET) Regenerated Polyester (RPET) Composite Staple Fiber (FZ/T52052-2018) . Having passed the certification of ISO 9001 for quality system, the certification for green fiber labels, the certification of OEKO-TEX Standard 100 for ecological textile products, the certification of Global Recycle Standard (GRS) global regeneration standards, etc.

Characteristics: The fiber is produced by using polyester and

modified polyester to spin simultaneously. The melting point is

below 130℃. It can mix with normal fiber to form the nonwoven, then

heat to bond them together and become an elastomer.

Use: Mattress of bed, seat cushions

2 . Specifications

| Name | 4080 Low Melting Polyester Staple Fiber |

| Material | Virgin |

| Denier | 2D |

| Cut Length | 51 MM |

| Color | White |

| Performance and features | 1. Combining regeneration and low melting point, low melting point

in sheath, low carbon content and environment friendly. 2. Soft feel, good bonding effect, stable heat shrinkage, easy of bonding with other fibers, and good elasticity. |

3. Application

| Application Technology | |

| Fiber Application | |

4. More pictures