Zhengzhou Zhongding Heavy Duty Machine Manufacturing Co., Ltd |

|

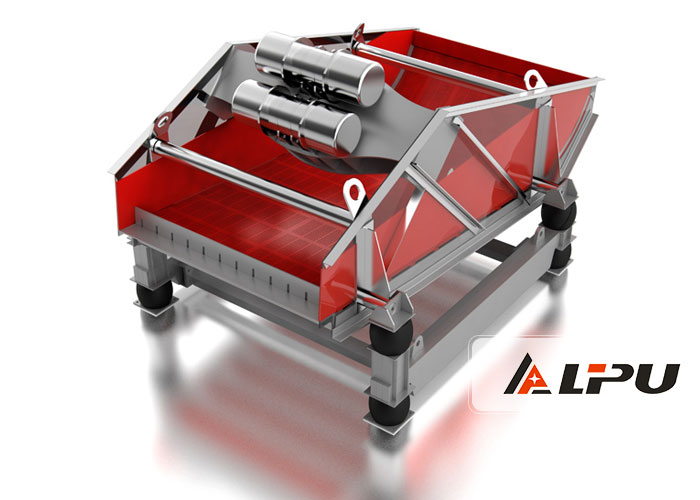

High Vibration Strength Dewatering Vibrating Screen for Sand Washing And Cleaning

Introduction:

Dewatering screen can be widely used in discharging dried tailing, sand washing plant, fine mineral dewatering, chip removing, carbon-in-pulp separation, etc.

Dewatering screen from Lipu machine has features of high vibration strength, large sieving area, the angle of screen box can be adjusted, compact structure, high performance, best price ratio, etc.

Screen mesh can be various types like polyurethane, nylon, stainless steel wire, manganese steel wire, industrial filter cloth, etc.

Working Principle of Sand Dewatering Screen:

The product adopts flange vibrator as power supply: The two motors that rotate synchronously and reversely and centrifugal force is produced by two groups of eccentric block. This makes the screen body periodical to-and-fro moving along the direction of straight line, which is for the purpose of dehydration. The screen frame is connected by the high-intensity bolts, so the structure is stable and durable.

If ore grinding and classification are closed loop operation, the return sand discharged from the ore discharge mouth still goes into the mill for further grinding.

Technical Parameters:

Model | Vibration frequency (r/min) | Screen Mesh Size (mm) | Capacity (t/h) | Power (kW) | Overall dimension (L×W×H)(mm) | Weight (t) |

GT1030 | 1450 | 0.1-2 | 10-30 | 2×1.5 | 3440×1680×2310 | 2.4 |

GT1230 | 1450 | 0.1-2 | 15-45 | 2×1.5 | 3440×1880×2310 | 2.6 |

GT1530 | 1450 | 0.1-2 | 20-60 | 2×2.25 | 3440×2180×2400 | 3 |

GT1836 | 1455 | 0.1-2 | 30-80 | 2×3.7 | 4140×2480×2530 | 4 |

Product Picture Show: