Henan Yukuang Machinery Manufacturing Co., Ltd |

|

After being processed, steel slag can be used as smelter flux, cement raw material, construction aggregate, foundation backfill, railway ballast, road pavement, brick, slag fertilizer and soil amendment, etc.

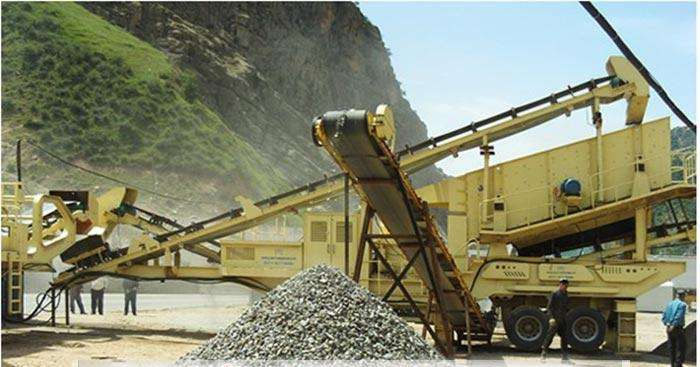

Vibrating feeder, jaw crusher, hydraulic cone crusher, vibrating screen, belt conveyor, magnetic separator.

Raw material (less than 350mm ) will be conveyed to vibrating feeder, grate of vibrating feeder is set to 100mm, material with size less than 100mm(from vibrating feeder) will be conveyed to cone crusher, material with size larger than 100mm will be conveyed to jaw crusher for primary crushing. The material from jaw crusher will be conveyed to cone crusher for secondary crushing, one magnetic separator is used in front of cone crusher for removing iron, and another magnetic separator is used behind cone crusher for removing steel chips from slag. The material after passing through magnetic separator will be conveyed to vibrating screen for screening; material with size larger than 10mm will be conveyed back to cone crusher for being crushed once again, material with size less than 10mm will be discharged as final product.

Steel slag is a kind of solid waste that is produced in the process of steel production, it mainly consists of blast furnace slag, steel slag, iron bearing dust (including iron oxide scale, dust, blast furnace dust, etc), coal dust, gypsum, rejected refractory, etc.

The pile of steel slag occupies a huge area of arable land, and causes environmental pollution; moreover, 7%-15% steel can be recycled from steel slag. After being processed, steel slag can be used as smelter flux, cement raw material, construction aggregate, foundation backfill, railway ballast, road pavement, brick, slag fertilizer and soil amendment, etc. Comprehensive utilization of steel slag can lead to enormous economic and social benefits.

Steel slag crushing production line adopts jaw crusher for primary crushing, and uses hydraulic cone crusher for secondary and tertiary crushing, offering high crushing efficiency, low wear, energy saving and environmental protection, it has the features of high automation, low operation cost and reasonable allocation of equipment.