Henan Ascend Machinery Equipment Co., Ltd. |

|

Vibrating Vibrator Screener 1 2 3 4YK2160 Sand Screen Mesh For Sale

Product Description

Circular Vibrating Screen has multiple layers, it is a new high efficient screen. It has characteristics reliable structure, low consumption, high screening efficiency, low vibrating noise, long durability, convenient maintenance, safe operation, etc. Our Vibrating Screen is widely used for screening in mines, building material, transportation, energy sources, chemical industry, etc.

Advantages of Vibrating Screen

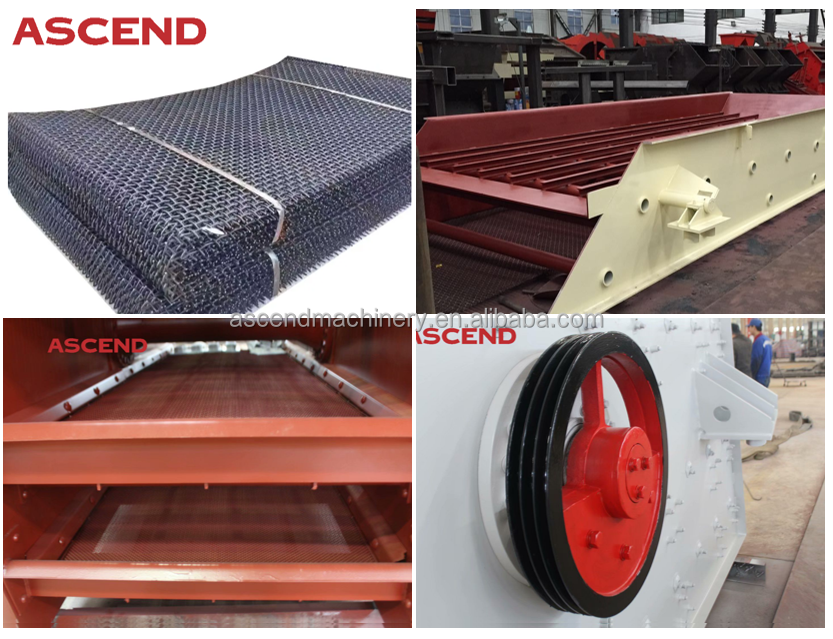

Detailed Images

Spare Parts

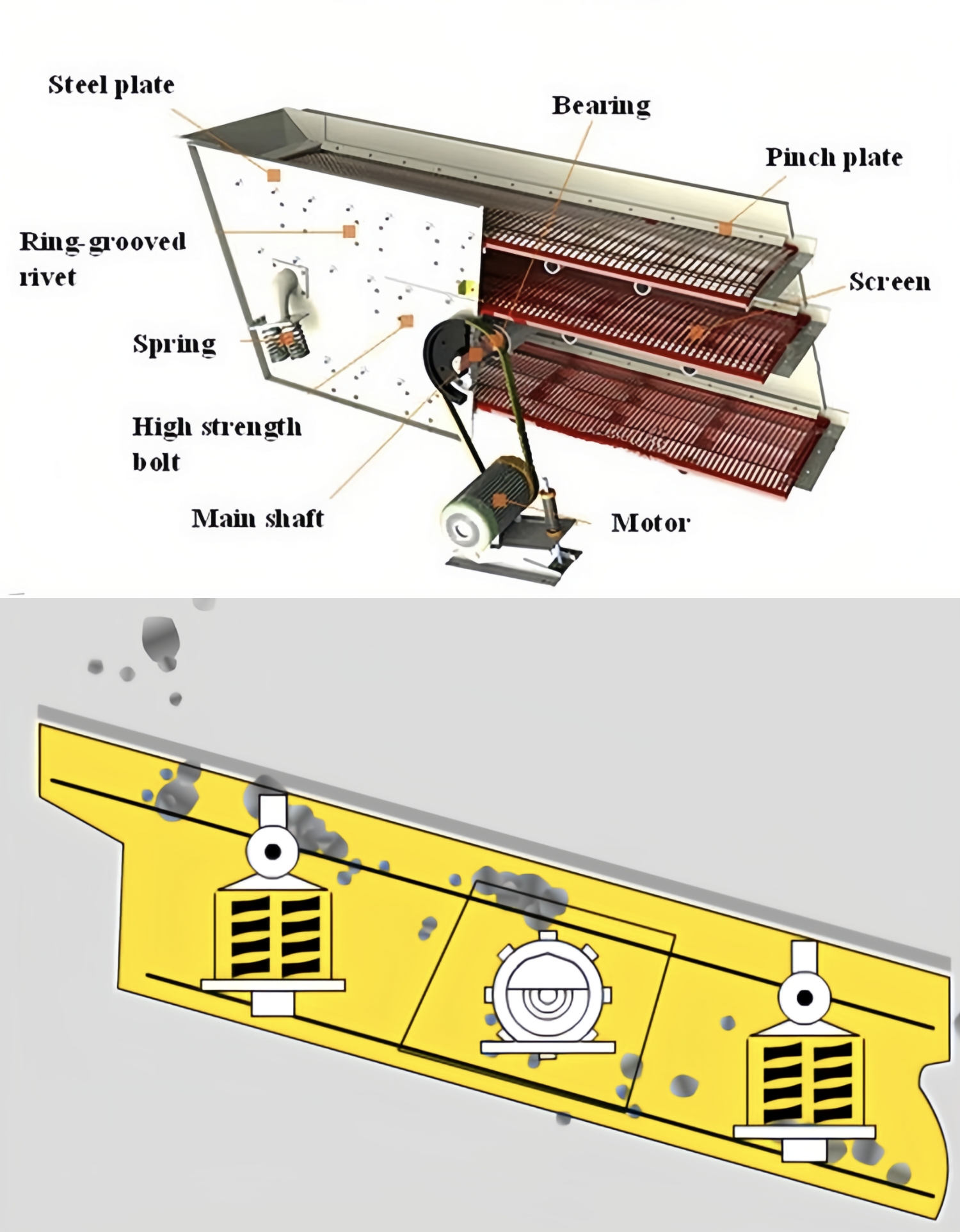

Working Principle

The electromotor drives the belt and pulley to make the movable jaw move back and forth, up and down through the eccentric shaft. The raw material is squashed or splitt when movable jaw plate moves towards fixed jaw together with movable jaw. When movable jaw and movable jaw plate turn back by eccentric shaft and spring, the raw material, which is squashed or split before discharges from the bottom outlet under jaw plate. The bulk-production comes true while electromotor rotates continuously and the movable jaw crushes and discharges the raw material periodically.

Main Technical Parameters

| Model | Screen layer | Screen area (m2) | Mesh size (mm) | Feeding size (mm) | Capacity (m3/h) | Vibrating frequency (r/min) | Double amplitude (mm) | Power (kw) | Dimension (L×W×H) | Weight (without motor) (t) | Screen slope (°) | Screen specification (mm) |

| YK1237 | 1 | 4.4 | 2-50 | 200 | 25-160 | 970 | 8 | 11 | 3857×2386×2419 | 4.8 | 15-20 | 1200×3700 |

| 2YK1237 | 2 | 4.4 | 2-50 | 200 | 25-160 | 970 | 8 | 11 | 3857×2386×2419 | 4.9 | 15-20 | 1200×3700 |

| 3YK1237 | 3 | 4.4 | 2-50 | 400 | 30-180 | 970 | 8 | 11 | 4057×2386×2920 | 5.2 | 15-20 | 1200×3700 |

| 4YK1237 | 4 | 4.4 | 2-50 | 400 | 30-180 | 970 | 8 | 11 | 4257×2386×2920 | 5.3 | 15-20 | 1200×3700 |

| YK1548 | 1 | 7.2 | 2-50 | 200 | 45-250 | 970 | 8 | 15 | 4904×2713×2854 | 5.9 | 15-20 | 1500×4800 |

| 2YK1548 | 2 | 7.2 | 2-50 | 200 | 45-250 | 970 | 8 | 15 | 4904×2713×2854 | 6.3 | 15-20 | 1500×4800 |

| 3YK1548 | 3 | 7.2 | 2-50 | 400 | 45-280 | 970 | 8 | 15 | 5104×2713×3106 | 6.5 | 15-20 | 1500×4800 |

| 4YK1548 | 4 | 7.2 | 2-50 | 400 | 45-280 | 970 | 8 | 18.5 | 5304×2713×3356 | 6.6 | 15-20 | 1500×4800 |

| YK1848 | 1 | 8.6 | 2-50 | 200 | 55-330 | 970 | 8 | 15 | 4904×3041×2854 | 6.2 | 15-20 | 1800×4800 |

| 2YK1848 | 2 | 8.6 | 2-50 | 200 | 55-330 | 970 | 8 | 15 | 4904×3041×2854 | 6.9 | 15-20 | 1800×4800 |

| 3YK1848 | 3 | 8.6 | 2-50 | 400 | 55-350 | 970 | 8 | 22 | 5104×3041×3106 | 7.2 | 15-20 | 1800×4800 |

| 4YK1848 | 4 | 8.6 | 2-50 | 400 | 55-350 | 970 | 8 | 22 | 5304×3041×3356 | 7.5 | 15-20 | 1800×4800 |

| YK1860 | 1 | 10.8 | 2-50 | 200 | 65-350 | 970 | 8 | 22 | 6166×3041×2854 | 6.4 | 15-20 | 1800×6000 |

| 2YK1860 | 2 | 10.8 | 2-50 | 200 | 65-350 | 970 | 8 | 22 | 6166×3041×2854 | 7.1 | 15-20 | 1800×6000 |

| 3YK1860 | 3 | 10.8 | 2-50 | 400 | 65-380 | 970 | 8 | 22 | 6366×3041×3106 | 7.4 | 15-20 | 1800×6000 |

| 4YK1860 | 4 | 10.8 | 2-50 | 400 | 65-380 | 970 | 8 | 30 | 6566×3041×3356 | 7.7 | 15-20 | 1800×6000 |

| YK2160 | 1 | 12.6 | 2-50 | 200 | 80-720 | 970 | 8 | 30 | 6166×3444×2854 | 9.9 | 15-20 | 2100×6000 |

| 2YK2160 | 2 | 12.6 | 2-50 | 200 | 80-720 | 970 | 8 | 30 | 6366×3444×3106 | 11.2 | 15-20 | 2100×6000 |

| 3YK2160 | 3 | 12.6 | 2-50 | 400 | 90-750 | 970 | 8 | 37 | 6566×3444×3356 | 12.4 | 15-20 | 2100×6000 |

| 4YK2160 | 4 | 12.6 | 2-50 | 405 | 90-750 | 970 | 8 | 45 | 6566×3444×3356 | 15.1 | 15-20 | 2100×6000 |

| YK2460 | 1 | 14.4 | 2-50 | 200 | 150-810 | 970 | 8 | 30 | 6166×3916×3839 | 12.2 | 15-20 | 2400×6000 |

| 2YK2460 | 2 | 14.4 | 2-50 | 200 | 150-810 | 970 | 8 | 30 | 6166×3916×3839 | 13.5 | 15-20 | 2400×6000 |

| 3YK2460 | 3 | 14.4 | 2-50 | 400 | 180-900 | 970 | 8 | 37 | 6366×3916×4139 | 13.6 | 15-20 | 2400×6000 |

| 4YK2460 | 4 | 14.4 | 2-50 | 400 | 180-900 | 970 | 8 | 45 | 6566×3916×4439 | 14.4 | 15-20 | 2400×6000 |

Packing&Shipping

Working Sites

Company Profile

Our Workshop

FAQ

Q1. Are you factory or trading company?

We are factory specialized in manufacturing stone crushers, grinding mills, beneficiation equipments and other mining equipments. Our office and factories are based in Zhengzhou, China. Because we are factory, so we can guarantee the machine quality and we can give you very competitive factory price without extra agent cost.

Q2. To which country your products have been exported before?

In Africa, We have exported to Sudan, Kenya, Zambia, Ethiopia, Zimbabwe, Guinea, Nigeria and so on. We also exported South Africa, Chile, Peru, Ecuador, New Zealand, America, Austrilia more than 160 countries. Our equipment and service have won very high reputation in these countries.

Q3. How will you help the customer install the equipment?

We will send our senior engineer to your place to guide the installation and commissioning.

Q4. How about the wear parts supply?

We offer wear parts to our customer with our most favorable price. If there are problems you could not handle, we will send our technicians to your place.

Q5.What about the payment method?

T/T, Paypal, Western Union, L/C is available.

Q6.What about after-sale service?

12 months warranty for all kinds of products; and you will get our 7*24h online service.

Related Products

Granite Barite Gypsum Horizontal Shaft Impact Crusher Mining And Building | Mining Rock Coal Hammer Mill Crusher Machine Electric Motor | Gravel Rock Granite Spring Symons Roller Cone Crusher |

PE250x400 Jaw Stone Crusher Machine | Grinding Gold Wet Pan Mill | Grinding Ball Mill Crusher |

Contact Us