Pasia Industries Ltd |

|

Electric Heat Tracing Element for Freeze Prevention of Pipework is a technical solution to the freeze prevention of pipework based on various options. In cold winter or areas, water or chemical pipework often needs to be heat traced to prevent freezing. Thermal insulation alone is incapable of preventing freezing. A 25mm bore pipe at 5°C having 25mm thick insulation will reach freezing point within one hour in an ambient temperature of -10°C.

Steam at, say 150°C, is not a viable fuel source for simple freeze protection and of course, condensate returns may themselves freeze. Electric heat tracing having a low power output is the most convenient and efficient option.

Take MI cable solution for example, Heat Trace Mineral Insulated Heating Cable can meet the needs of high temperature condition and heat tracing of long-distance transportation pipeline or other various process pipelines. The maximum withstand temperature of the copper sheathed heating cable (MICU) provided by MICH can reach up to 250℃. Conductor resistance value ranges from 1.7-2000Ω/km. For the occasion of anti-corrosion or buried application, high density polyethylene (HDPE) outer sheath ( cable known as MIHC) is needed to be added. MIHC’s withstanding maximum temperature can be up to 90℃. Mineral insulated heating cable possesses excellent mechanical strength. The heating cable of series resistance provided by MICH can meet the requirements of different power levels.

High-temperature heat pipes are typically defined as heat pipes that operate between 400 and 1100°C. However, the fluid properties vary too much across this wide temperature range for any one of those fluids. Three fluids are typically used to cover this range; Cesium, Potassium, and Sodium. The operating range for each fluid is shown below:

Cesium 300 to 600°C (572 to 1,112°F)

Potassium 400 to 1000°C (752 to 1,832°F)

Sodium 500 to 1100°C (932 to 2,012°F)

Typical applications for high-temperature heat pipes include the following:

1. Heat Engine Receivers (Steam, Stirling, Brayton, Rankine)

2. Solar Thermal

3. Heat exchangers

4. Hypersonic wing leading edges

5. Waste heat recovery

6. Nuclear power

7. Thermoelectric Generators

8. Isothermalizing furnace elements

Cable Structure

Specification

Heating cable instruction code

MI CU-B 16K320/60/2520/220/E1

No. 1 2 3 4 5 6 7

| No. | Instruction | |

| 1 | Sheath material | CU |

| 2 | structure of cable components | shown in table 1 |

| 3 | cable codes | shown in table 2, 3 and 4 |

| 4 | length of heating cable | In meter |

| 5 | Heating cable power | In Watt |

| 6 | heating cable voltage | In Volt |

| 7 | heating cable voltage | See table 5 |

Cable Code

1 6 K 320

No. 1 2 3 4

| Serial NO. | Instruction | |

| 1 | core number | 1 or 2 |

| 2 | Voltage grade | 3=300V, 6=600V |

| 3 | conductor materials | C,K |

| 4 | cold resistance ×1000 | 320=0.32Ω/m×1000 |

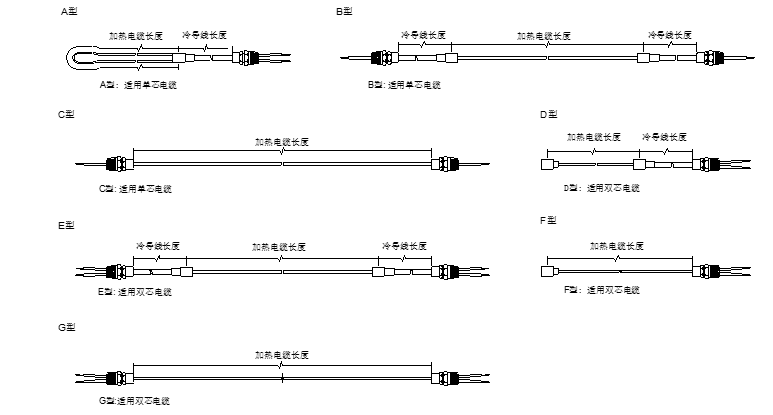

Table 1 Structure of Cable Element

Note: Model C, F and G are suitable for being used at temperature under 65℃

Table 2 Heating Cable Specification (600V Single Conductor)

| Cable Code | Diameter | HDPE Diameter | Standard resistance value at +20℃ | Maximum Production Length | Unit weight |

| mm | mm | Ω/m | m | kg/km | |

| 16C1.7 | 8.2 | 10 | 0.0017 | 350 | 366.54 |

| 16C2.2 | 7.6 | 9.4 | 0.0022 | 380 | 307.77 |

| 16C2.9 | 7.0 | 8.8 | 0.0029 | 400 | 264.45 |

| 16C4 | 5.9 | 7.7 | 0.004 | 600 | 190.88 |

| 16C7 | 5.3 | 7.1 | 0.007 | 600 | 154.08 |

| 16C11 | 4.9 | 6.7 | 0.011 | 600 | 132.25 |

| 16C13 | 4.6 | 6.4 | 0.013 | 600 (300)☆ | 125.7 |

| 16C17 | 4.6 | 6.4 | 0.017 | 600 (300)☆ | 117.16 |

| 16C21 | 4.6 | 6.4 | 0.021 | 600 (300)☆ | 111.9 |

| 16C25 | 3.7 | 5.5 | 0.025 | 600 (480)☆ | 68.83 |

| 16C33 | 3.7 | 5.5 | 0.033 | 600 (480)☆ | 63.76 |

| 16C40 | 3.4 | 5.2 | 0.04 | 600 (560)☆ | 58.87 |

| 16C63 | 3.2 | 5 | 0.063 | 600 | 51.47 |

| 16K80 | 6.8 | 8.6 | 0.08 | 370 (140)☆ | 254.18 |

| 16K100 | 5.2 | 7 | 0.1 | 450 (240)☆ | 162.11 |

| 16K140 | 4.9 | 6.7 | 0.14 | 600 (270)☆ | 122.55 |

| 16K197 | 4.45 | 6.25 | 0.197 | 600 (330)☆ | 111.32 |

| 16K220 | 4.5 | 6.3 | 0.22 | 600 (330)☆ | 102.89 |

| 16K315 | 4.3 | 6.1 | 0.315 | 600 (350)☆ | 91.44 |

| 16K345 | 4.2 | 6.0 | 0.345 | 600 (370)☆ | 85.9 |

| 16K450 | 4.0 | 5.8 | 0.45 | 600 (400)☆ | 80.73 |

| 16K630 | 4.0 | 5.8 | 0.63 | 600 (400)☆ | 77.26 |

| 16K800 | 3.5 | 5.3 | 0.8 | 600 (530)☆ | 61.48 |

| 16K1250 | 2.8 | 4.6 | 1.25 | 600 | 40.83 |

| 16K2000 | 2.8 | 4.6 | 2.0 | 600 | 38.96 |

Table 3 Heating Cable Specification (600V Double Conductors)

| Cable Code | Diameter | Nominal resistance at +20℃ | Maximum manufacturing length | Unit weight |

| mm | Ω/m | m | kg/km | |

| 26C3.4 | 12.9 | 0.0034 | 150 | 783.76 |

| 26C4.4 | 12.2 | 0.0044 | 160 | 701.56 |

| 26C5.8 | 11.3 | 0.0058 | 170 | 606.16 |

| 26C8.6 | 9.90 | 0.0086 | 180 | 451.43 |

| 26C11.4 | 9.30 | 0.0114 | 200 | 400.05 |

| 26C13.8 | 9.00 | 0.0138 | 210 | 375.20 |

| 26C17.2 | 8.60 | 0.0172 | 220 | 344.90 |

| 26C23 | 8.00 | 0.023 | 250 | 303.25 |

| 26C34.4 | 7.50 | 0.0344 | 280 | 269.20 |

| 26C49.2 | 7.10 | 0.0492 | 300 | 243.84 |

| 26K240 | 9.90 | 0.24 | 180 | 451.43 |

| 26K320 | 9.30 | 0.32 | 200 | 400.05 |

| 26K384 | 9.00 | 0.384 | 210 | 375.20 |

| 26K480 | 8.60 | 0.48 | 220 | 344.90 |

| 26K640 | 8.00 | 0.64 | 250 | 303.25 |

| 26K960 | 7.50 | 0.96 | 280 | 269.20 |

Table 4 Heating Cable Specification (300V Double Cores)

| Cable Code | Diameter | Nominal resistance at +20℃ | Maximum manufacturing length | Unit weight |

| mm | Ω/m | m | kg/km | |

| 23C3.4 | 12.0 | 0.0034 | 200 | 708.10 |

| 23C4.4 | 11.3 | 0.0044 | 220 | 629.07 |

| 23C5.8 | 10.4 | 0.0058 | 240 | 537.73 |

| 23C8.6 | 9.00 | 0.0086 | 260 | 392.56 |

| 23C11.4 | 8.40 | 0.0114 | 280 | 343.89 |

| 23C13.8 | 8.00 | 0.0138 | 300 | 314.57 |

| 23C17.2 | 7.60 | 0.0172 | 320 | 286.27 |

| 23C23 | 7.10 | 0.023 | 340 | 252.98 |

| 23C34.4 | 6.60 | 0.0344 | 360 | 221.19 |

| 23C49.2 | 6.20 | 0.0492 | 380 | 197.64 |

| 23K160 | 10.4 | 0.16 | 220 | 508.37 |

| 23K240 | 9.00 | 0.24 | 240 | 392.56 |

| 23K320 | 8.40 | 0.32 | 265 | 343.89 |

| 23K384 | 8.00 | 0.384 | 280 | 314.57 |

| 23K480 | 7.70 | 0.48 | 300 | 291.91 |

| 23K640 | 7.10 | 0.64 | 320 | 252.98 |

| 23K960 | 6.50 | 0.96 | 350 | 216.11 |

Note: the resistance value of 2-core cable in the above table is the measured value after the ends are twisted (i.e., single-core resistance X2);

For the use of 660V voltage occasions, please contact our company professionals;

Mark of (300)☆ is a recommended production length by MICH

Table 5 terminal specifications

| Model: A, D, E | Model: B | |||||

| Maximum Voltage(V) | Maximum Current (A) | Terminal Specification | Maximum Voltage(V) | Maximum Current (A) | Terminal Specification | Maximum Voltage(V) |

| 600 | 15 | E2 | 20 | E1 | 15 | E1 |

| 600 | 20 | E2 | 25 | E2 | 20 | E1 |

| 600 | 30 | E3 | 40 | E2 | 30 | E2 |

| 600 | 50 | E3 | 70 | E2 | 50 | E2 |

| 600 | 70 | E3 | 100 | E3 | 70 | E2 |

Note 2: the length of cold end cable with standard configuration is 2 meters. If you increase or decrease of length required, please contact our professional personnel.

Corresponding reference table between the output power and sheath temperature

Note: when applying a copper conductor heating cable, please pay attention to the conversion of its heated hot resistance and unheated cold resistance.

Anticorrosive specification

| Material | MICU | MIHC |

| Sulfate | Not recommend | Excellent |

| Hydrochloric acid | Not recommend | Excellent |

| Hydrofluoric acid | Acceptable | Acceptable |

| Phosphate | Acceptable | Acceptable |

| Carbonate | Not recommend | Acceptable |

| Organic acid | Acceptable | Not recommend |

| Alkali metal | Acceptable | Acceptable |

| Sea water | Not recommend | Acceptable |

| Chloride | Data checking required | Acceptable |

Explosion-proof instructions

MIAL series heating cable with explosion-proof terminal, can be used in potential explosive environment. Authenticated by the Chinese CQST, in accordance with Chinese GB3836 explosion-proof electrical standards, they can be applicable to Ⅱ A, Ⅱ B, Ⅱ C (C1D2) level of explosion-proof electrical equipment.