Pasia Industries Ltd |

|

Mineral Insulated Electric In-line Heater for Direct Heat Supply is ideal for processing fluid, including hazardous liquids with requirement of intermediate heat supply to make the flow rate. Unlike the heat acquisition from a heat exchanger, an In line water heater can supply heat to the fluid by transfering simply the heat from electrical power. It possesses good properties of high heat transfer efficiency, the covenience to install and to maintain, and excellent compatibility with industrial piping. Applications, eg. waste oil, steam and water processing, can adopt in-line heaters in order to regulate and control the temperature, but also to maintain the fluid viscosity. An improper liquid viscosity could gradually slow down the overall processing time of the production. In addition, the product’s final yield and purity could also be affected by a slight deviation of the viscosity. To avoid this type of problem, a heater inline is used to heat the fluid so that at the proper temperature, the viscosity remains unchanged and at the same time to process the medium at a desirable steady flow rate. To control the liquid flow rate of the heater, the wattage can be manipulated and regulated to obtain the desired temperature (in other words, the flow rate is directly proportional to the temperature/liquid viscosity).

Second, technical properties

1. The heat transfer performance of the heating element of this product is good, and the temperature difference between the heating core and the metal sheath is small. At the same time, according to the process requirements, the surface heat load density of the heating element of the MI heating cable can be accurately designed. Under the premise of ensuring the total heating power, the heated medium will not coke. It solves the shortcomings of the traditional tubular electric heaters for long-term carbon deposition, blasting, core breaking and short life. The heating element can with a copper or a stainless steel sheath according to the application temperature and location.

2. The outer shell of the electric heater is welded by seamless steel pipe and flange. The overall structure is tight and firm and the pressure sealing performance is good for safe use. The normal working pressure is 0.6MPa~6.4MPa.

3. The device connection and electrical connection meet the explosion-proof requirements with an explosion-proof grade d IIBT1—T6.

4. Two sets of temperature sensors are installed in electric heater to detect the temperature of the oil and the surface temperature of the heating element. At the same time, the flow locking device can be optionally selected according to the user's needs. When the medium does not flow, the electric heater automatically stops heating.

5. No daily maintenance is required and it is easy to be installed and convenient to be maintained.

6. The product is practical and adaptable. Various non-standard types of electric heaters can be designed according to the different uses and special requirements put forward by users.

Note: When designing an electric heater for using outdoors, the explosion-proof junction box should have a rainproof shed to prevent rainwater from impregnating the gap of the explosion-proof surface through the wet insulation material.

Third, structure and working principle

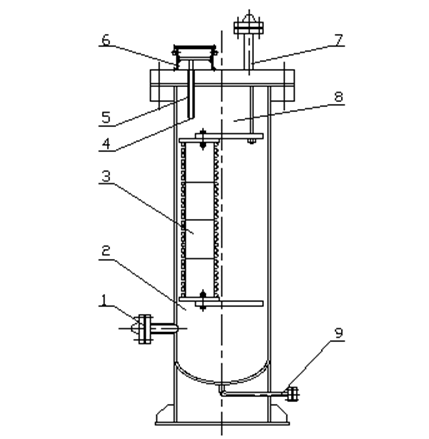

The electric heater structure consists of nine parts. (See Figure 1)

1 Inlet pipe 2 Diversion Chamber 3 Heating Chamber 4 Temperature Measuring Resistor 5 Over Temperature Protector 6 Junction Box 7 Oil Outlet Pipe 8 Mixed Flow Chamber 9 Sewage Outlet

Figure 1: Schematic diagram of liquid electric mineral insulated heater

2. Working Principle

The cold medium enters the diversion chamber through the oil inlet, so that the medium flows into the mixing chamber along the periphery of the heating element, and the mixed medium flows out from the oil outlet at a uniform temperature. The mixing chamber is equipped with a temperature measuring sensor, and the temperature signal is collected and transmitted to the electronic control system. The temperature control instrument controls the primary circuit to realize automatic control of the oil temperature. When the oil products or electric heating element of the heater is overheated, the protection device automatically cuts off the power supply and the control cabinet emits an audible and visual alarm signal.

Fourth, technical specification

1. Model meaning

2. Technical data

The main technical data are shown in Table 1.

Table 1 Technical Data and Outer Dimension Sheet for Vertical Electric Heater

| Model | Rated Power (Kw) | Rated Voltage (V) | Rated Current (A) | Power Phase | Outer Dimension(mm) | Body Weight (Kg) | ||||

| h1 | H | D | 6.3 MPa | 4.0 MPa | 2.5 MPa | |||||

| YDRQ-3/220/L | 3 | 220 | 13.5 | 1 | 180 | 720 | φ219 | 165 | 105 | 90 |

| YDRQ-5/220/L | 5 | 220 | 22.5 | 1 | 180 | 860 | φ219 | 175 | 120 | 105 |

| YDRQ-7.5/220/L | 7.5 | 220 | 34 | 1 | 180 | 1100 | φ219 | 190 | 130 | 115 |

| YDRQ-10/3/380/L | 10 | 380 | 15 | 3 | 400 | 1000 | φ273 | 240 | 200 | 165 |

| YDRQ-15/3/380/L | 15 | 380 | 22.5 | 3 | 400 | 1474 | φ273 | 280 | 240 | 210 |

| YDRQ-20/3/380/L | 20 | 380 | 30 | 3 | 544 | 1100 | φ377 | 475 | 320 | 260 |

| YDRQ-30/3/380/L | 30 | 380 | 45 | 3 | 544 | 1544 | φ377 | 530 | 370 | 290 |

| YDRQ-50/3/380/L | 50 | 380 | 75 | 3 | 544 | 1850 | φ377 | 640 | 510 | 430 |

| YDRQ-80/3/380/L | 80 | 380 | 120 | 3 | 600 | 2425 | φ500 | 930 | 700 | 510 |

| YDRQ-100/3/380/L | 100 | 380 | 150 | 3 | 648 | 1850 | φ600 | 1200 | 960 | 710 |

| YDRQ-150/3/380/L | 150 | 380 | 226 | 3 | 648 | 2920 | φ600 | 1550 | 1050 | 820 |

| YDRQ-200/3/380/L | 200 | 380 | 300 | 3 | 648 | 3200 | φ600 | 1790 | 1240 | 900 |

| YDRQ-250/3/380/L | 250 | 380 | 375 | 3 | 822 | 3482 | φ1000 | 5000 | 3800 | 2900 |

| YDRQ-300/3/380/L | 300 | 380 | 450 | 3 | 822 | 3850 | φ1000 | 6200 | 4950 | 3240 |

| YDRQ-600/3/380/L | 600 | 380 | 910 | 3 | 910 | 4854 | φ1200 | 8000 | 6900 | 5800 |

Table 2 Technical Data and Outer Dimension Sheet for Horizontal Electric Heater

| Model | Rated Power (Kw) | Rated Voltage (V) | Rated Current (A) | Power Phase | Outer Dimension(mm) | Body Weight (Kg) | |||||

| L | L1 | L2 | D | 6.3 MPa | 4.0 MPa | 2.5 MPa | |||||

| YDRQ-3/220/W | 3 | 220 | 13.5 | 1 | 1100 | 750 | 450 | φ159 | 85 | 55 | 45 |

| YDRQ-5/220/W | 5 | 220 | 22.5 | 1 | 1300 | 1000 | 750 | φ159 | 100 | 60 | 50 |

| YDRQ-7.5/220/W | 7.5 | 220 | 34 | 1 | 1650 | 1300 | 1000 | φ159 | 110 | 65 | 52 |

| YDRQ-10/3/380/W | 10 | 380 | 15 | 3 | 1460 | 1050 | 750 | φ219 | 180 | 160 | 130 |

| YDRQ-15/3/380/W | 15 | 380 | 22.5 | 3 | 1720 | 1400 | 1200 | φ219 | 200 | 170 | 140 |

| YDRQ-20/3/380/W | 20 | 380 | 30 | 3 | 2000 | 1620 | 1300 | φ219 | 220 | 180 | 150 |

| YDRQ-30/3/380/W | 30 | 380 | 45 | 3 | 2210 | 1850 | 1340 | φ219 | 240 | 190 | 160 |

| YDRQ-50/3/380/W | 50 | 380 | 75 | 3 | 2750 | 2200 | 1600 | φ273 | 400 | 315 | 240 |

| YDRQ-80/3/380/W | 80 | 380 | 120 | 3 | 3550 | 3100 | 2100 | φ377 | 735 | 560 | 490 |

| YDRQ-100/3/380/W | 100 | 380 | 150 | 3 | 2950 | 2400 | 1750 | φ530 | 1000 | 750 | 580 |

| YDRQ-150/3/380/W | 150 | 380 | 226 | 3 | 3500 | 3000 | 2300 | φ530 | 1185 | 850 | 640 |

| YDRQ-200/3/380/W | 200 | 380 | 300 | 3 | 4350 | 3800 | 2650 | φ530 | 1350 | 1000 | 720 |

| YDRQ-250/3/380/W | 250 | 380 | 375 | 3 | 4100 | 3600 | 2800 | φ630 | 1900 | 1450 | 1050 |

| YDRQ-300/3/380/W | 300 | 380 | 450 | 3 | 4100 | 3600 | 2800 | φ630 | 1950 | 1500 | 1100 |

| YDRQ-600/3/380/W | 600 | 380 | 910 | 3 | 4500 | 4000 | 3200 | φ1000 | 5100 | 3800 | 2200 |