Changzhou Vic-Tech Motor Technology Co., Ltd. |

|

Verified Suppliers

|

|

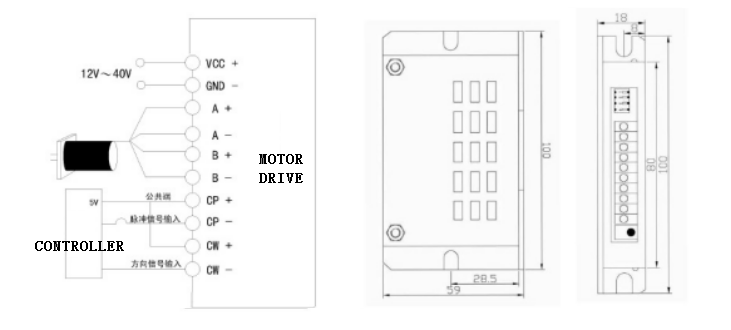

SWT-201M driver drives two-phase stepping motor. The driver adopts imported module to realize high frequency chopping and constant current drive. It has strong anti-interference, high frequency performance, high starting frequency, control signal and internal signal. It realizes photoelectric isolation, current selection, simple structure, stable operation, good reliability and low noise, and drives all stepping motors below 1.0A.

Since its launch on the market, it has been well received by users, especially in the fields of stage lighting, automation, instrumentation, POS machines, engraving machines, ticket printers, industrial marking printers, semiconductor diffusion furnaces, etc.

SWT-201M driver drives two-phase stepping motor. The driver adopts imported module to realize high frequency chopping and constant current drive. It has strong anti-interference, high frequency performance, high starting frequency, control signal and internal signal. It realizes photoelectric isolation, current selection, simple structure, stable operation, good reliability and low noise, and drives all stepping motors below 1.0A.

Since its launch on the market, it has been well received by users, especially in the fields of stage lighting, automation, instrumentation, POS machines, engraving machines, ticket printers, industrial marking printers, semiconductor diffusion furnaces, etc.

Typical Applications

Suitable for stepper motors up to 1A in current

1. VCC ≤24V connected to DC voltage

2. A+ connected to stepper motor A phase

4. A-connected stepper motor A phase

5. B+ connected to stepper motor B phase

6. B-connected stepper motor B phase

7. CP+ connected to external controller +5V output

8. CP-connected to external controller pulse signal output (forward direction pulse output)

9 CW+ is connected to external controller +5V output

10 CW-Connect to external controller direction signal output (reverse direction pulse output)

(1) What is a stepper motor and a stepper drive?

Stepper motor is a special motor specially designed for precise control of speed and position. Its rotation is operated step by step at a fixed angle (called "step angle"), so it is called stepper motor. Its characteristic is that there is no accumulated error, every pulse signal sent from the controller is received, and the motor runs at a fixed angle under the drive of the driver, so it is widely used in various open-loop control.

The stepping driver is a power amplifier that can operate the

stepping motor. It can convert the pulse signal sent by the

controller into the power signal of the stepping motor. The speed

of the motor is proportional to the pulse frequency, so the control

pulse frequency can be precisely adjusted. Speed, the number of

control pulses can be accurately positioned.

(2) What is the breakdown of the drive?

The stepper motor is determined by its own unique structure, and the “inherent step angle of the motor” (such as 1.2°/0.6°) is indicated at the factory. However, in many precision control and occasions, the angle of the whole step is too large, affecting the control precision, and the

vibration is too large. Therefore, it is required to complete the inherent step angle of a motor in many steps. This is called a subdivision drive and can realize this function. The electronic device is called a subdivision driver.

Because the step angle that has passed each step is reduced, the step uniformity is improved, so the control accuracy can be improved.

The vibration of the motor can be greatly reduced. The low-frequency oscillation is an inherent characteristic of the stepper motor. Subdivision is the best way to eliminate it.

It can effectively reduce torque ripple and increase output torque.

These advantages are generally recognized by users and bring them benefits, so it is recommended that you use subdivision drivers.

(4) Why does my motor only work in one direction?

The pulse mode does not match, the signal is pulse/direction, the driver must be set to this mode; if the signal is CW/CCW (double pulse mode), the driver must also be in this mode, otherwise the motor will only run in one direction.