Changzhou Vic-Tech Motor Technology Co., Ltd. |

|

Verified Suppliers

|

|

SWT-256M is a high-performance subdivided stepper motor driver

designed by our factory using advanced pure sinusoidal precision

current control technology. The pure sinusoidal precision current

control technology adopted by SWT-256M can improve the above

problems well, so that the running effect of the stepping motor is

close to the servo level to some extent.

This drive also has multiple subdivisions, small size, multiple

protections and automatic semi-flow functions. Users can use

SWT-256M voltage up to 40VDC.

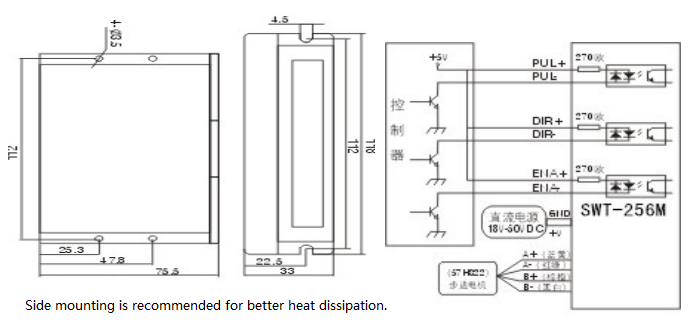

Mechanical Dimension:MM

Technical Features

I. Overview

SWT-256M is a high-performance subdivided stepper motor driver

designed by our factory using advanced pure sinusoidal precision

current control technology. The pure sinusoidal precision current

control technology adopted by SWT-256M can improve the above

problems well, so that the running effect of the stepping motor is

close to the servo level to some extent.

This drive also has multiple subdivisions, small size, multiple

protections and automatic semi-flow functions. Users can use

SWT-256M voltage up to 40VDC.

Second, the wiring instructions

1.P1 weak wiring signal description

Signal function

PUL+(+5V) Pulse signal: pulse control signal, the rising edge of

the pulse is valid at this time; P-5 is 4-5V at high level and

0-0.5V at low level for reliable response, the pulse width is

greater than 1μS. If +12V or +24V is used, string resistor current

limiting is required.

PUL-(PUL)

DIR+ (+5V) direction signal: high/low level signal, in order to

ensure reliable response of the motor, corresponding to the forward

and reverse of the motor. The direction signal should be

established at least 5μs before the pulse signal. The initial

running direction of the motor is related to the wiring of the

motor. Interchanging any phase winding (such as A+, A-exchange) can

change the direction of the initial running of the motor. When

DIR-high level 4 -5V, 0-0.5V at low level.

DIR-(DIR)

ENA+(+5V) Enable signal: This input signal is used to

enable/disable, high level enable, and the driver does not work

when low level. Under normal circumstances, you must not connect,

so that it is suspended and automatically enabled.

ENA-(ENA)

2.P2 strong interface description

Interface function

GND DC power ground

+V DC power supply is positive, any value between +30V-+40V can be

used, but the recommended value is +36VDC.

A+, A- Motor A phase. A+, A-intermodulation, can change the

direction of motor running.

B+, B- Motor B phase. B+, B-intermodulation, can change the

direction of motor running.

Product Detail Presentation

Working (dynamic) current setting

| Current peak | SW1 | SW2 | SW3 | |

| 1.4A | OFF | OFF | OFF | |

| 2.1A | ON | OFF | OFF | |

| 2.7A | OFF | ON | OFF | |

| 3.2A | ON | ON | OFF | |

| 3.8A | OFF | OFF | ON | |

| 4.3A | ON | OFF | ON | |

| 4.9A | OFF | ON | ON | |

| 5.6A | ON | ON | ON |

Subdivision setting

Subdivision accuracy is set by SW5-SW8 four-position dial switch

Subdivision factor | Steps / circle (1.8°/full step) | SW5 | SW6 | SW7 | SW8 |

| 2 | 400 | OFF | ON | ON | ON |

| 4 | 800 | ON | OFF | ON | ON |

| 8 | 1600 | OFF | OFF | ON | ON |

| 16 | 3200 | ON | ON | OFF | ON |

| 32 | 6400 | OFF | ON | OFF | ON |

| 64 | 12800 | ON | OFF | OFF | ON |

| 128 | 25600 | OFF | OFF | OFF | ON |

| 5 | 1000 | ON | ON | ON | OFF |

| 10 | 2000 | OFF | ON | ON | OFF |

| 20 | 4000 | ON | OFF | ON | OFF |

| 25 | 5000 | OFF | OFF | ON | OFF |

| 40 | 8000 | ON | ON | OFF | OFF |

| 50 | 10000 | OFF | ON | OFF | OFF |

| 100 | 20000 | ON | OFF | OFF | OFF |

| 125 | 25000 | OFF | OFF | OFF | OFF |

Stepper motor is a special motor specially designed for precise control of speed and position. Its rotation is operated step by step at a fixed angle (called "step angle"), so it is called stepper motor. Its characteristic is that there is no accumulated error, every pulse signal sent from the controller is received, and the motor runs at a fixed angle under the drive of the driver, so it is widely used in various open-loop control.

The stepping driver is a power amplifier that can operate the

stepping motor. It can convert the pulse signal sent by the

controller into the power signal of the stepping motor. The speed

of the motor is proportional to the pulse frequency, so the control

pulse frequency can be precisely adjusted. Speed, the number of

control pulses can be accurately positioned.

(2) What is the breakdown of the drive?

The stepper motor is determined by its own unique structure, and the “inherent step angle of the motor” (such as 1.2°/0.6°) is indicated at the factory. However, in many precision control and occasions, the angle of the whole step is too large, affecting the control precision, and the

vibration is too large. Therefore, it is required to complete the inherent step angle of a motor in many steps. This is called a subdivision drive and can realize this function. The electronic device is called a subdivision driver.

Because the step angle that has passed each step is reduced, the step uniformity is improved, so the control accuracy can be improved.

The vibration of the motor can be greatly reduced. The low-frequency oscillation is an inherent characteristic of the stepper motor. Subdivision is the best way to eliminate it.

It can effectively reduce torque ripple and increase output torque.

These advantages are generally recognized by users and bring them benefits, so it is recommended that you use subdivision drivers.

(4) Why does my motor only work in one direction?

The pulse mode does not match, the signal is pulse/direction, the driver must be set to this mode; if the signal is CW/CCW (double pulse mode), the driver must also be in this mode, otherwise the motor will only run in one direction.