Baoji Lihua Nonferrous Metals Co., Ltd. |

|

Verified Suppliers

|

|

Ti-0.3Mo-0.8Ni Gr12 Titanium pipes seamless titanium pipe 25.4mm ASTM SB338

Gr12 Titanium (Ti-0.3Mo-0.8Ni) Titanium alloy is a

corrosion-resistant titanium alloy, a near-alpha alloy developed to

improve the crevice corrosion performance of pure titanium. The

alloy is strengthened, and it has good crevice corrosion resistance

to high temperature, low pH chloride or weakly reducing acid, and

its corrosion resistance is significantly better than pure titanium

and close to Gr9 alloy. Gr12 alloy also has good process plasticity

and welding performance, and has been widely used in the chemical

industry. The alloy can be used in the annealed state.

Density 4.54g / m3, room temperature elastic modulus 103 ~ 107GPa,

hardness HB180 ~ 215, phase transition point 890 ± 15 ℃.

Corrosion resistance: Nickel improves the crevice corrosion resistance of titanium in hydrochloric acid solution, but in reducing acid, the corrosion resistance of Ti-Ni alloy is lower than pure titanium. The proper addition of molybdenum to Ti-Ni alloy can improve its corrosion resistance in reducing medium.

Corrosion resistance: Nickel improves the crevice corrosion resistance of titanium in hydrochloric acid solution, but in reducing acid, the corrosion resistance of Ti-Ni alloy is lower than pure titanium. The proper addition of molybdenum to Ti-Ni alloy can improve its corrosion resistance in reducing medium.

| Product name | Titanium pipe |

| Material | Titanium Gr12 (Ti-0.3Mo-0.8Ni ) |

| Certificates | ISO9001:2015, TUV, EN10204.3.1 |

| Standard | ASTM B338 |

| Size | OD19.1mm 25.4mm 33.4mm 38.1mm 45mm WT:0.5-1.5mm Length>=12000mm |

| Surface | Acid pickling, CNC lathe surface. |

| Technique | Rolled |

| Status | Annealed(M) |

| Types | Seamless and welded |

| Applications | Chemical industry, such as Heat exchanger etc. |

| ASTM No. | Fe max | O max | N max | C max | H max | Mo | Ni | Bal |

| Grade 12 | 0.30 | 0.25 | 0.015 | 0.08 | 0.015 | 0.2-0.4 | 0.6-0.9 | Ti |

| ASTM Grade | Alloy Composition | Tensile Strength | Yield Strength | Elongation min % | ||

| ksi | Mpa | ksi | Mpa | |||

| Grade 12 | Unalloyed Ti ("Pure") 50A -CP2 | 58 | 400 | 40 | 275 | 25 |

Titanium pipes pictures:

The titanium tubes produced by our company are mainly ASTM B338 standard, suitable for titanium heat exchangers, etc.

The processing technology of titanium and titanium alloy seamless tube blanks mainly includes extrusion method and diagonal rolling piercing method. Gr12 Ti-0.3Mo-0.8Ni titanium alloy industrial production tube blanks are mainly produced by extrusion, and there are few reports about cross-rolling and perforation. Compared with the production of seamless pipes by extrusion, the oblique rolling piercing method not only has a short process and high efficiency, but also improves the material utilization rate and reduces costs, which is in line with the concept of energy saving and environmental protection. Our company uses a two-roller cross-rolling and piercing process to prepare TA10 titanium alloy seamless pipes, and explores the heat treatment process of seamless pipes to obtain pipes with comprehensive mechanical properties.

Baoji Lihua has more than 15 years of experience in the production and export of titanium pipes. We have our own factory and production equipment, so we can guarantee the qualityand delivery time of the flange. In addition to domestic sales, all of our flanges are strictly produced in ASTM B338, ASTM B861, ASTM B862.The Titanium pipes we produce is mechanically polished, the surface is flat and smooth, and the dimensions are precise,strictly in accordance with standard tolerances. We choose class 1 titanium sponge as the raw material ,and the titanium flange we produced both mechanical properties and chemical composition can meet export standards.

Our company is certified by ISO9001:2008 and IQNET. Our company have long-term cooperated with international inspection agency, such as SGS,BV, LR'S ,TUV etc.Welcome customers to do the third party test to our products.

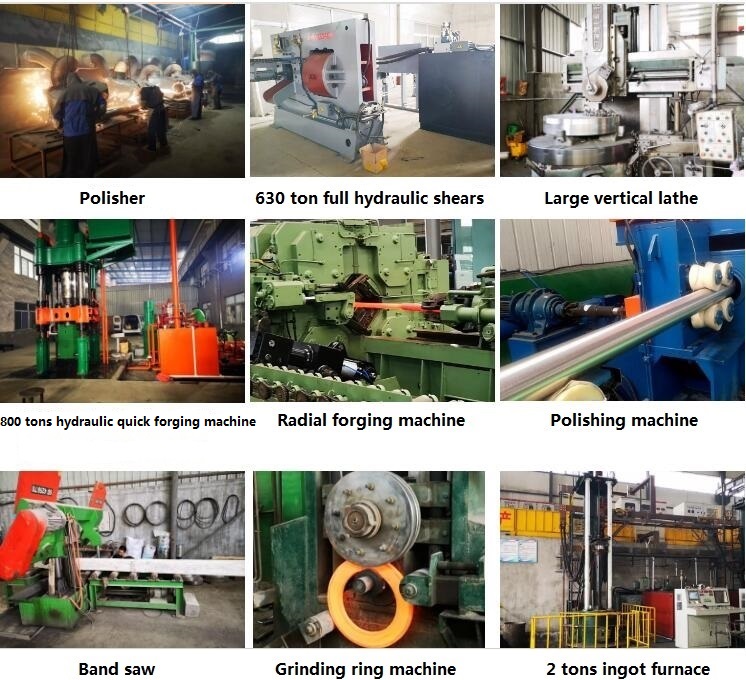

Our factory mechanical equipments:

We are available in any time!