Xi 'an Dongmeng Steel Co., Ltd |

Factory direct sale aisi 201 304 2b cold rolled stainless steel coil price best

stainless steel coil

stainless steel coil Element composition and application

| 200 series(Cr-Mn-Ni) | 201,202 |

| 300 series(Cr-Ni) | 301, 302, 304, 304l,309, 310(S), 316(L), 321, etc |

| 400 series(Cr) | 401,409, 410, 420j1,420j2,430,439,etc. |

Element action:

Carbon ( C ): 1. Improve the deformation resistance and tensile strength of the blade; 2. Increase hardness and wear resistance.

Chromium (CR): 1. Improve hardness, tensile strength and toughness; 2. Wear and corrosion resistance.

Cobalt (CO): 1. Increase hardness and strength so that it can withstand high temperature quenching; 2. It is used to strengthen some individual properties of other elements in more complex alloys.

Copper (Cu): 1. Enhance corrosion resistance; 2. Enhance wear resistance.

Manganese (MN): 1. Increase hardenability, wear resistance and tensile strength; 2. Removing oxygen from molten metal by separation oxidation and separation vaporization; 3. When added in large quantities, it improves the hardness, but improves the brittleness.

Molybdenum (MO): 1.Enhance strength, hardness, hardenability and toughness; 2. Improve machinability and corrosion resistance.

Nickel (Ni): 1. Enhance strength, hardness and corrosion resistance.

Phosphorus (P): 1. Enhanced strength, machinability and hardness. 2. It is easy to crack when the concentration is too high

Silicon (SI): 1. Improve ductility; 2. Increase tensile strength; 3. Remove oxygen from molten metal by separate oxidation and separate vaporization.

Sulfur (s): 1. Use in small quantities to improve machinability.

Tungsten (W): 1. Increase strength, hardness and toughness.

Vanadium (V): 1. Increase strength, hardness and seismic resistance.2.Prevent the generation of particles.

Because stainless steel has many ideal properties required by

building materials, it can be said to be unique in metals, and its

development continues. In order to make stainless steel more

neutral in traditional applications, existing types have been

improved, and new stainless steel is being developed to meet the

strict requirements of advanced architectural applications. Due to

the continuous improvement of production efficiency and quality,

stainless steel has become one of the most cost-effective materials

selected by architects. Stainless steel integrates performance,

appearance and use characteristics, so stainless steel will still

be one of the best building materials in the world.

| NamName | ThicThicknesskness | WidthWidth |

| Stainless steel hot rolled coil | 1.5-15mm | 1000mm 1219mm 1500mm 1800 mm 2000mm |

| Cold rolled stainless steel coil | 0.3-3.0mm | 1000mm 1219mm 1500mm |

| Stainless steel cold rolled coil | 0.1-3.0mm | 500mm 1600mm |

| Common materials:201,202,301,304,309(S),310(S),316(L),321,409,410,430,etc. | ||

| If the customer's demand is large, we can cut it according to the customer's size Another can do wire drawing plate, anti - slide plate, electroplating plate. | ||

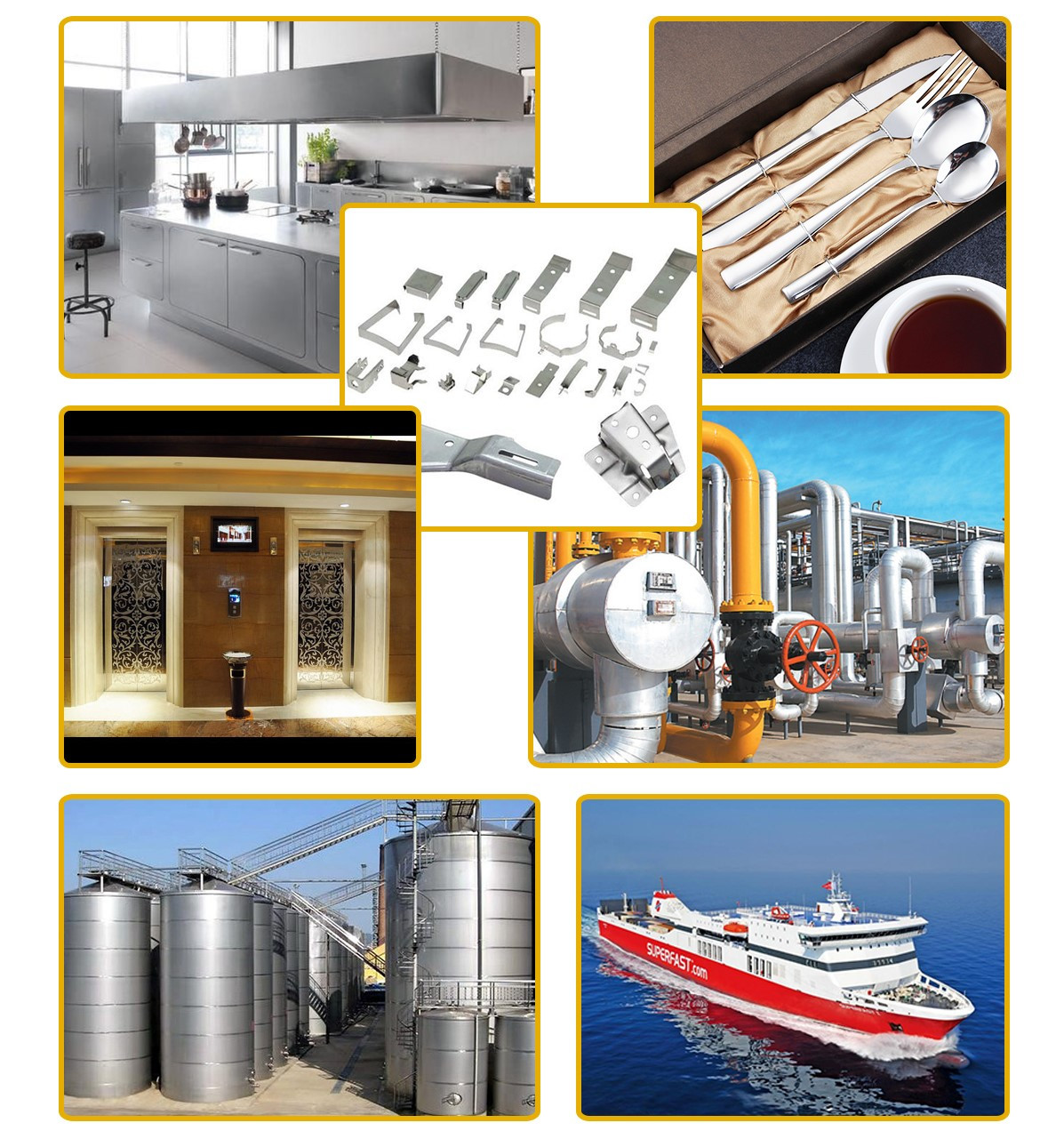

Stainless steel coil is widely used in chemical industry, food, medicine, papermaking, petroleum, atomic energy and other industries, as well as various parts of buildings, kitchenware, tableware, vehicles and household appliances.

| ||

200 series: Cr Mn Ni

201: it is a high manganese and low nickel stainless steel with low

nickel content and poor corrosion resistance. It is widely used in

all kinds of tabletops, countertops, kitchenware, outdoor

decoration engineering, urban decoration industry and high-grade

household products.

202: stainless steel is widely used in architectural decoration,

municipal engineering, highway guardrails, hotel facilities,

shopping malls, glass handrails, public facilities and other

places.

300 series: Cr Ni austenitic stainless steel

301: good ductility, used for molding products. It can also be

hardened rapidly by machining. Good weldability. The wear

resistance and fatigue strength are better than 304 stainless

steel.

302: the corrosion resistance is the same as that of 304. Because

the carbon content is relatively high, the strength is better.

303: it is easier to cut than 304 by adding a small amount of

sulfur and phosphorus.

304: general model; 18 / 8 stainless steel. Products such as:

corrosion resistant containers, tableware, furniture, railings,

medical equipment. The standard ingredient is 18% chromium plus 8%

nickel. It is a non-magnetic stainless steel whose metallographic

structure cannot be changed by heat treatment. The GB brand is

06cr19ni10.

304 L: it has the same characteristics as 304, but it is low

carbon, so it is more corrosion resistant and easy to heat

treatment, but its mechanical property is poor. It is suitable for

products that are welded and difficult to heat treatment.

304N: with the same characteristics as 304, it is a

nitrogen-containing stainless steel. Nitrogen is added to improve

the strength of the steel.

309: better temperature resistance than 304, up to 980 ℃.

309S: with a large amount of chromium and nickel, it has good heat

resistance and oxidation resistance. Products such as heat

exchanger, boiler components and jet engine.

310: excellent high temperature oxidation resistance, with a

maximum service temperature of 1200 ℃.

316: after 304, the second most widely used steel is mainly used in

food industry, watch accessories, pharmaceutical industry and

surgical equipment. Molybdenum is added to obtain a special

corrosion-resistant structure. Because it has better chloride

corrosion resistance than 304, it is also used as "marine steel".

SS316 is usually used in nuclear fuel recovery units. Grade 18 / 10

stainless steel generally meets this application grade.

316 L: low carbon, so it is more corrosion-resistant and easy to

heat treatment. Products such as chemical processing equipment,

nuclear power generator and refrigerant storage tank.

321: in addition to reducing the risk of weld corrosion due to the

addition of titanium, other properties are similar to 304.

347: add stabilizing element niobium, which is suitable for welding

aviation appliance parts and chemical equipment.

400 series: Ferritic and martensitic stainless steel, manganese

free, can replace 304 stainless steel to a certain extent

408: good heat resistance, weak corrosion resistance, 11% Cr, 8%

Ni.

409: the cheapest model (British and American), usually used as

automobile exhaust pipe, is ferritic stainless steel (chromium

steel).

410: martensite (high strength chromium steel), good wear

resistance and poor corrosion resistance.

416: sulfur was added to improve the processability of the

material.

420: "cutting tool grade" martensitic steel, similar to the

earliest stainless steel such as Brinell high chromium steel. It is

also used for surgical tools, which can be made very bright.

430: ferritic stainless steel, for decoration, such as automotive

accessories. Good formability, but poor temperature resistance and

corrosion resistance.

440: high strength cutting tool steel, with slightly higher carbon

content, can obtain higher yield strength after appropriate heat

treatment, and the hardness can reach 58hrc. It is one of the

hardest stainless steels. The most common application example is

"razor blade". There are three common models: 440A, 440b, 440C, and

440f (easy to process).

500 Series: heat resistant chromium alloy steel.

600 Series: Martensitic precipitation hardening stainless steel.

Element action:

Carbon ( C ): 1. Improve the deformation resistance and tensile strength of the blade; 2. Increase hardness and wear resistance.

Chromium (CR): 1. Improve hardness, tensile strength and toughness; 2. Wear and corrosion resistance.

Cobalt (CO): 1. Increase hardness and strength so that it can withstand high temperature quenching; 2. It is used to strengthen some individual properties of other elements in more complex alloys.

Copper (Cu): 1. Enhance corrosion resistance; 2. Enhance wear resistance.

Manganese (MN): 1. Increase hardenability, wear resistance and tensile strength; 2. Removing oxygen from molten metal by separation oxidation and separation vaporization; 3. When added in large quantities, it improves the hardness, but improves the brittleness.

Molybdenum (MO): 1.Enhance strength, hardness, hardenability and toughness; 2. Improve machinability and corrosion resistance.

Nickel (Ni): 1. Enhance strength, hardness and corrosion resistance.

Phosphorus (P): 1. Enhanced strength, machinability and hardness. 2. It is easy to crack when the concentration is too high

Silicon (SI): 1. Improve ductility; 2. Increase tensile strength; 3. Remove oxygen from molten metal by separate oxidation and separate vaporization.

Sulfur (s): 1. Use in small quantities to improve machinability.

Tungsten (W): 1. Increase strength, hardness and toughness.

Vanadium (V): 1. Increase strength, hardness and seismic resistance.2.Prevent the generation of particles.

Because stainless steel has many ideal properties required by

building materials, it can be said to be unique in metals, and its

development continues. In order to make stainless steel more

neutral in traditional applications, existing types have been

improved, and new stainless steel is being developed to meet the

strict requirements of advanced architectural applications. Due to

the continuous improvement of production efficiency and quality,

stainless steel has become one of the most cost-effective materials

selected by architects. Stainless steel integrates performance,

appearance and use characteristics, so stainless steel will still

be one of the best building materials in the world.

Packing&Shipping

Standard Export Seaworthy Package.Suitable for all kinds of

transport,or follow clients' request

Packing Details : Bundle with steel strip, waterproof paper and

plastic coverage

Delivery Details : Use wooden trays to facilitate loading and

unloading

20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High)

40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High)

40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High)

20 feet container can load 25 to 26 tons products whose length is

under 5.8m

40 feet container can load 25 to 26 tons products whose length is

under 11.8m

FAQ