Suzhou Vanforge Metals Co., Ltd. |

|

ASTM A106 GRB GRC Seamless carbon steel boiler pipe for high temperature service

ASTM A106 seamless pressure pipe (also known as ASME SA106 pipe) is commonly used in the construction of oil and gas refineries, power plants, petrochemical plants, boilers, and ships where the piping must transport fluids and gases that exhibit higher temperatures and pressure levels.

ASTM A106 pipe (also covered in ASME specifications as S/A 106) is the standard specification for seamless carbon steel pipe for high-temperature service. Most common uses are in refineries and plants when gasses or fluids are transported at high temperatures and pressures. Federal Steel Supply is a world leader in the supply of A106 / SA 106 pipe and stocks a full range of grades B/C in a size rage of NPS 1/8″ to NPS 48″, with nominal (average) wall thickness as given in ANSI B36.10. Pipe having other dimensions may be furnished provided such pipe complies with all other requirements of this specification*. Pipe ordered under this specification shall be suitable for bending, for flanging, for welding, and for similar forming operations. A full range of A106 stock is available in Schedules 10 through 160, STD, XS, XXS. Unscheduled wall thicknesses available up to 4 inches.

ASTM A106 pipe (also covered in ASME specifications as S/A 106) is the standard specification for seamless carbon steel pipe for high-temperature service.

Description

Sunny Steel Supply stocks a full range of A106 seamless carbon steel pipe.

1. standards: ASTM A106 (ASME SA106)

2. products mainly used: apply to bending, curling and similar forming process.

3. the main products of steel / steel grade: Gr.A; Gr.B; Gr.C.

4. Specifications: diameter: 10.3 to 114.3 mm thickness: 0.8 to 12 mm Length: 6 m above, and, in accordance with customer demand, supply and other specifications of steel pipe.

5. Chemical composition and mechanical properties

6. JIS Number and Corrensponding Foreign Standards

ASTM A106 Seamless Carbon Steel Pipe High Temperature Standard Specification for Seamless Carbon Steel Pipe for High-Temperature

ASTM Scope:

This specification covers seamless carbon steel pipe for high-temperature service in NPS 1/8 to NPS 48 inclusive, with nominal (average) wall thickness as given in ASME B 36.10M. It shall be permissible to furnish pipe having other dimensions provided such pipe complies with all other requirements of this specification. Pipe ordered under this specification shall be suitable for bending, flanging, and similar forming operations, and for welding. When the steel pipes are to be joined together, it is presupposed that a welding procedure suitable to the grade of steel and intended use or service will be utilized.

Product Knowledge:

Common uses include pressure piping at high temperatures (piping for water, air or steam, etc.). Though the product is described as for “high temperatures”, ASME allows for use as low as -20F (-29C). It can be used upwards of 800F (427C), though the SA106 allowable stresses drop significantly above 400F (200C).

Note that A106 allows only seamless pipe manufacturing techniques. This means that you will never see ERW/HFIW or DSAW A106 pipes.

This ASTM specification is written so that the end user and the manufacturer can agree upon, and clearly understand, the properties and capabilities of the piping product being supplied. In contrast with national codes (like API, ASME or CSA), ASTM A106 is rarely stipulated by national or state-level legal requirements.

Rather than “re-invent the wheel”, ASME has recognized the widespread use of this product, and has adopted the A106 standard for use in pressure vessel (BPVC) and pressure piping (B31.X) applications. The details of this can be found in ASME Boiler and Pressure Vessel Code (BPVC) Section IIA, and is identified as SA106. Note that there may be minor exceptions in the SA version of ASTM standards, and the engineers, end users, purchasers and Manufacturer must comply. Note also that there is often a 5 to 10 year lag between the approved ASTM edition and the approved ASME edition. This means that there can be minor differences between the two specifications. Most engineers who spec SA106 product will also prefer to follow the requirements of the more recent ASTM version (which is usually also more strict), resulting in the common notation ASTM/ASME A/SA106 on the product documentation.

Note that there is a lower limit on manganese (Mn) in ASTM A106 of around 0.30% Mn, though you will typically see at least twice this much (around 0.60% Mn). For products that are hot rolled, it will be more common to see values of 0.80 to 1.20% Mn, as the increased alloying is necessary to attain the strength requirements of the standard. Because of these considerations, this product will commonly have a Mn/C ratio of 3 to 5 depending on the production method. Therefore, ASME B31.3 limits the low temp application of SA106 Grade B products to above -20F (-29C). That being said, for lower temp applications approaching -20F, many engineers may choose to spec specific low-temp products (such as SA333) for these applications.

A106 does not have its own table of pipe dimensions. Rather, like A333 and API 5L, it reverts to ASME B36.10 for the nominal pipe dimensions. Therefore, A106 pipe products are often multi-certified to similar ASTM A53, A333 and API 5L grades, where the requirements of all these specifications are met.

Note that for welding SA106 products, ASME BPVC Section IX considers SA106 GrB to be in the P1G1 alloy grouping (along with SA53 GrB, SA333 Gr6), while SA106 GrC is in the P1G2 alloy grouping.

Though A106 GrA exists in the standard, and most Manufacturer of seamless pipe claim to be able to make it, it is quite rare to see this grade stocked in North America, and it would be considered unusual to spec A106 GrA in a piping system.

It is interesting that hydrotesting is not required for this standard, provided that non-destructive testing has been performed, such as ultrasonics or eddy current inspection, and was determined to be capable of full-thickness inspection (i.e., it must have been volumetric NDT). When the hydrotesting option is chosen instead of NDT, the test pressure will be at 60% of the burst pressure of the pipe.

Basic Product Properties:

A106 GrA:

30 ksi (205 MPa) min. YS

48 ksi (330 MPa) min. UTS

Not Impact Tested

A106 GrB:

35 ksi (240 MPa) min. YS

60 ksi (415 MPa) min. UTS

Not Impact Tested

A106 GrC:

40 ksi (275 MPa) min. YS

70 ksi (485 MPa) min. UTS

Not Impact Tested

ASTM A106 Gr B Seamless Pipes- process of making it?

ASTM A106 Gr B Seamless Pipes are usually used in the gas refineries, ships, and boilers where the piping should transmit gases or fluids that absorb higher pressure and temperatures levels. It is also used in petrochemical plants, power plants, and creation of oil. Such pipes cover carbon steel seamless nominal tube getting high-temperature service. The pipe is right and suitable for flanging, blending as well as similar forming operations. Under NPS 1-1/2″ it may be either cold drawn and hot finished or under NPS 2″ is finished unless specified.

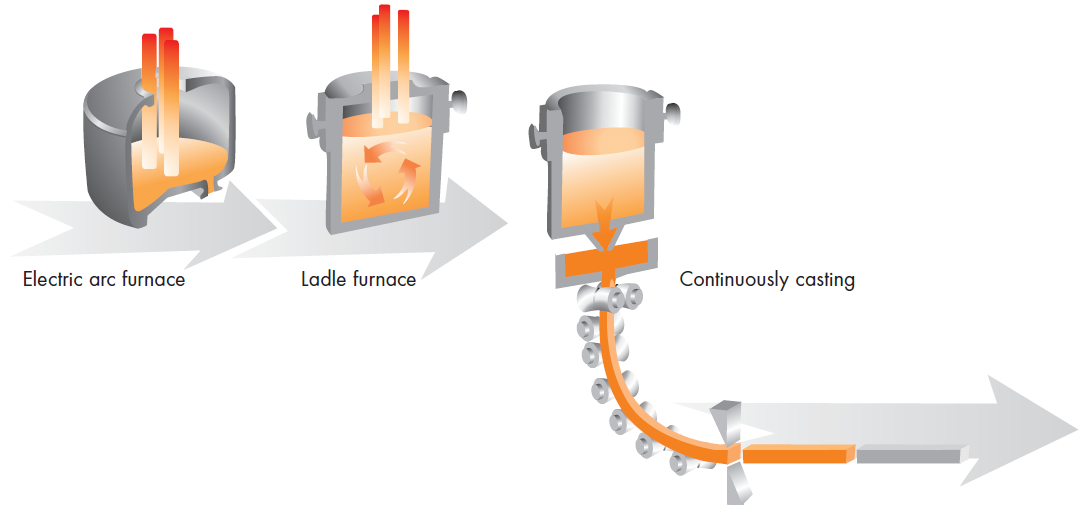

Process-

These seamless pipes are manufactured by killing steel with the initial melting method being basic oxygen, electric furnace and open-hearth may be blended with individual refining or degassing. Strand cast and steel cast in ingot is permissible. Then, the hot finished pipe does not need heat treatment and the cold drawn pipe is given heat treatment once the last cold draw passed out. This way, the pipes are made and it will need some modern equipment to be prepared.

Making of pipes-

While buying it, you can see the manufacturer brand's name on its box. Also, the full specification would be given on its outer parts such as pipe length, NPS size, designated schedule, heat number, NDE, hydrostatic test pressures, and thickness.

The good thing about ASTM A106 Gr B Seamless Pipes does not get corrode even under any circumstances and its poses long life services. Numbers of suppliers who are being supplied this material to all at the affordable price.

Carbon Steel ASTM A106 Gr B Seamless Pipe Specifications

Standard : ASTM A106 / ASME SA106 Grade B

Outside Diameter: 325-1067 mm

Wall Thickness: 9.53-140 mm

Length: On the request

Forms : Round Pipes and Tubes

End : Plain End, Beveled End, Treaded

Production procedure