Hangzhou bluesteel machine co., ltd |

|

Verified Suppliers

|

|

ASTM A653 DX51 Galvanized Steel Coil And Sheet , Cold Rolled Steel Sheet In Coil

hot dipped galvanized steel coils/prepainted galvanized sheets coils.(PPGI)

prepainted steel coil/prepained gavalume steel coil(PPGL)

cold rolled coil/strip

galvalume steel coil

galvanized steel coil

black steel pipe

galvanized steel pipe

corrugated steel sheet(GI/GL/PPGI)

PPGI/PPGL(color coated steel or prepainted steel coil) is a kind of steel plate with organic coating. Color steel plate is divided into single board, color steel composite board, floor board and so on. Widely used in large public buildings, public factories, movable board houses, and integrated house walls and roofs.

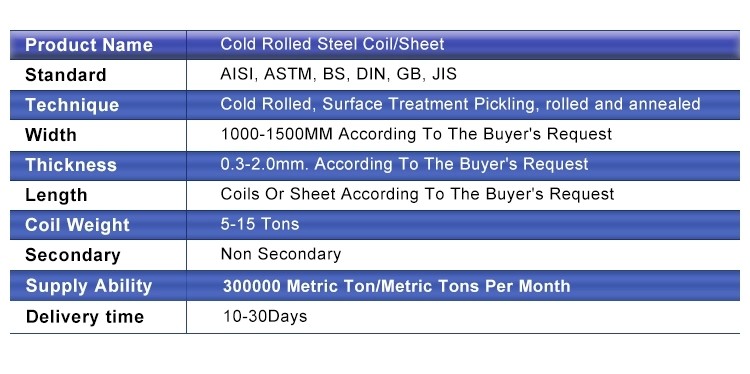

Description:

galvanized steel coil

1. Zinc coating:40-275g/m2( as required)

2.Thickness:0.14-3.0mm

3. Width:600-1500mm(900mm,1215mm,1250mm,1000mm)

4. Coil id:508mm

5. Coil weight: 3-5MT(as required)

6. Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

7. Application:galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration,etc.

Galvanized steel coils are widely used in the construction industry,as raw material for the production of corrugated panels,fencing products,etc.Recommended

for both outside and inside usage,galvanized steel has a high resistance to corrosion in different environments,due to a protective layer of zinc of 40-275 grams per square meter.Hot dip galvanized steel coils are produced by immersing steel in a zinc bath.An appropriate galvanizing process requires a pretreatment process during which the steel passes through

different baths which prepare the surface for zinc coating. In this stage, chemicals are used to clean the surface of the steel. After the chemical treatment, the steel coils pass through a bath of melted zinc

at temperatures around 460°C.The resulting uniform coating is finished through a process of skin-passing to provide smooth and shiny appearance of the finished product.To store for a longer period,the hot-dip galvanized coils can be delivered with a final oil coating, according to the customer’s demand.