Hangzhou bluesteel machine co., ltd |

|

Verified Suppliers

|

|

The roof tile panel is formed by corrugated forming machine from

high quality coated sheet, which performs elegant style of

traditional roof tile and suits for every architecture design. With

light, strong strength and long lasting quality, also it is

convenient and takes short time for installation.

The line is for continuously roll forming and pressing step tile on

series profile. The length is unlimited andstep depth can be as

customers’ requirement.

Hangzhou Bluesteel Machine CO.,LTD specialized in manufacturing and exporting:

1) wall & roof forming machine

2) step tile. Ridge cap roll forming machine

3) EPS/PU sandwich panel line

4) C&Z purlin machine

5) metal decking forming machine

6) shutter door roll forming machine

7) rain spout forming machine

8) slitting line

9) cut to length line

10) guardrail roll forming machine

Technical data of steel corrgated roll forming machine

Suitable material | color steel sheet;0.3-07mm, |

Working speed | about2-3m/min |

stress | 235MPa,345MPa,550MPa. |

Power | Main motor power: 5.5 Kw(Depend on final design) |

Hydraulic station power: 4Kw(Depend on final design) | |

Material of forming rollers | No.45 steel, plated with chrome on surface. |

Material of cutter,pressing die | Cr12 mould steel with quench treatment, HRC58-60 |

Material of shaft | High quality 45# steel, Roller grinder milling. |

Shaft diameter | 72mm |

Controlling system | Mitsubishi PLC & converter |

Total weight of machine | About 9500KGS |

Machine’s size | about 18m×1.8m× 1.5m (Depend on final design) |

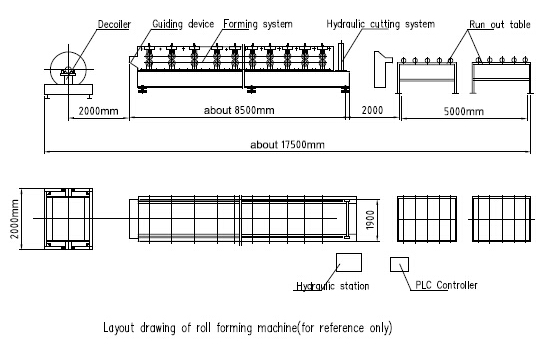

Layout drawing of machine

Our Roll Forming Machine’s advantages

1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome .to protect surface shiniing and strong

2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation.and hardness 60 degree.

3. Cutter blade: Cr12 mould steel with quenched treatment, long life time.

4. High precision: shafts for rollers are tooled by grinding machine. Rollers are CNC processed to ensure precision performance.

5 .automatic PLC : introduced Mitsubishi PLC with touch screen ,inverter,transformer.

6. powerful driving system: big inch train,or gear box driving system.

6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines.

producing process:

We can also customize the products according to customer ' s requirements