DLY Metal Roofing Machine |

|

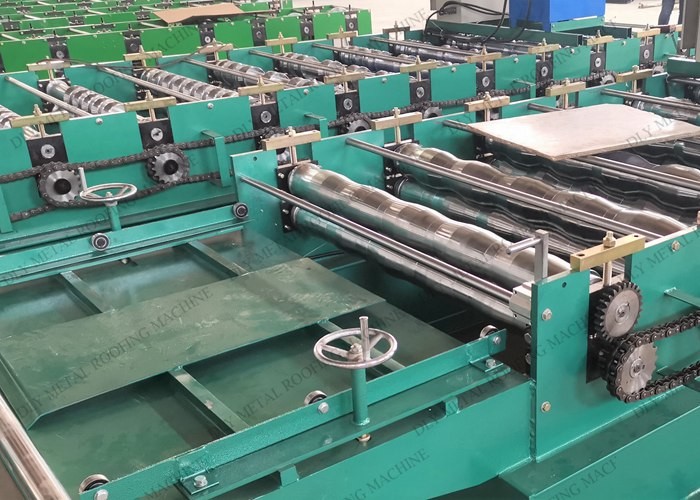

380V 1250mm PLC Sheet Metal Forming Machine With Hydraulic Cutting

1. Brief introduction of Trapezoidal Roll Forming Machine

we use bigger solid shaft diameter 80mm, which give bigger support during forming and can use for many years without deformation. 24roller station guarantee the final product precise and smooth. This roll forming machine weight about 13tons, that is mean, we use about 18ton raw material to make this forming machine.

besides, roll forming machine parts are Exquisite processed, for example, one set rollers will be processed by two days on our 12 CNC machine.

The last but no least, Mitsubishi or Siemens control system adopt to guarantee easy operation and stable factions.

roll forming Machines before delivery, well installed, test many times to its best status. You are welcomed to test our machines in our factory. Or we will help you check every details your concern.

Once rollforming machine arrive your factory,you only connect some wires and tubes according to our instruction book and video. Our technicians and engineers can assist you in your factory if your required.

Standard roll forming machines component(working speed about 15-20m/min, 7 ton manual decoiler, forming system with post cut, hydraulic station, PLC controller, run out table without power

2. Description of Trapezoidal Roll Forming Machine

No. | main parameter of CORRUGATED roll forming machine | |

1 | Suitable to process | Color steel plate, galvanized sheet, aluminum coils and etc. |

3 | Roller station | 18 rows |

4 | Thickness of feeding material | 0.3-0.7mm |

5 | Power | 4+3kw |

7 | Productivity | 8-12m/min |

8 | Diameter of the roller | Φ70mm |

10 | Size | 8500*1300*1400mm |

11 | Voltage | 380V 50Hz 3phases |

12 | Rolling material | Carbon Steel 45# |

13 | Material of the cutting plate | Cr12 |

14 | Wall thickness of main forming machine | 20mm steel plate |

15 | Main forming machine body | 400 mm H steel |

16 | Control system | PLC control |

Can be customized according to customer requirements or drawings | ||

3. After-Sale Service of Trapezoidal Roll Forming Machine

- Provide Pre-sales Consultant & On-purchase service & After-sales service 24hr × 7days per week

- Give technical suggestion

- Test the machine before shipment

- Provide technical guidance relate to use the machine

- Supply one-year warranty period for the machine

- Provide the spare parts at cost price after warranty period

- Collect the feedback for the machine working

- Provide long-term technical assistance.

4. Detail photos of Trapezoidal Roll Forming Machine