DLY Metal Roofing Machine |

|

Hydraulic Cutting 380v 5.5kw Pipe Profiling Machine For Gutter Downspout

1. Description of Pipe Profiling Machine

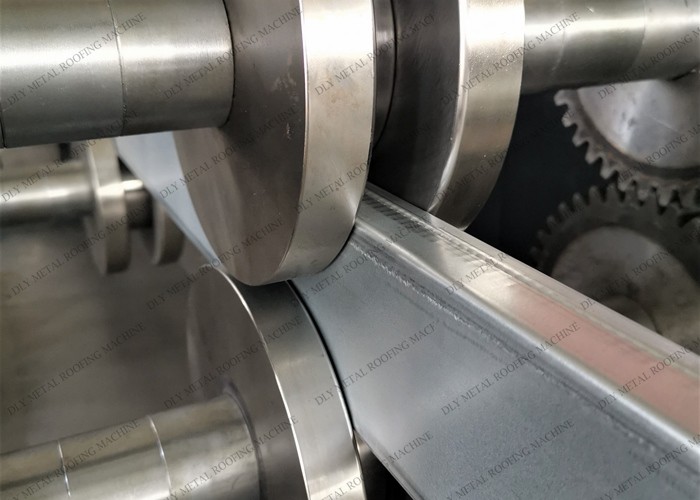

Square downpipe rain pipe rolling forming machine is designed to

make the rain pipe in batch fully automatically.

Our downspout pipe making machine could be used to make downspout

pipes in a higher speed and good quality. For this machine, we take

guide column frame style to make machine for making sure machine

working speed and steady. And for the transmission, we will use

gearbox with chain.

2. Specifications of Pipe Profiling Machine

Technical Parameters of Downpipe Roll Forming Machine:

* Uncoiler: Manual Uncoiler

* Inner diameter: 508mm

* Outer diameter: 1200mm

* Loading weight: 3T

* Thickness of Material: 0.4-0.6mm

* Rolling Stations: 22 stations for square pipe and 26 stations for

round pipes.

* Forming Speed: 10-15m/min. (not including cutting)

* Diameter of Shaft: ¢70mm

* Transmission: by chain-brackets

* Main Power: 7.5KW

* Weight of the machine appro.6 Tons.

* Cutting Type: Hydraulic cutting for rectangular downpipe and

Flying Saw Cutting for Circle downspout

* Hydraulic Power: 4KW

* Material of cutter blade: Cr12 steel with quenched treatment.

* Cutting Length and Quantity: Clients can set the required length

and quantity on the PLC touchscreen

* Electrical System for Rectangular Downspout Roll Forming Machine

* Panasonic PLC Control System and Omron Encoder;

Passive uncoil— Feeding—Roll forming—Cut to length—Output

table—Elbow with pipe

4. Detail Photos of Pipe Profiling Machine

The processing and detail of each part, the assembly of the machine, all determine the quality of a machine. We strive to do a good job in every link, every process, so that the machine in the process of use can be more stable, longer service life.