DLY Metal Roofing Machine |

|

6T 380V Metal Pipe Profiling Machine For Rain Water Steel Down Spout

1. Description of Pipe Profiling Machine

1. Touch screen control equipment, easy to use

2. The surface finish of the production profile is good. The galvanized plate does not hurt the zinc, the color coat does not drop the paint, and the shape can be highly matched the design drawing.

3. Mechanical equipment are sturdy and durable, less failure, and low maintenance costs.

4. Low waste rate of profile production, Save production cost.

2. Specifications of Pipe Profiling Machine

3TonX600mm Hydraulic Un-Coiler | Hydraulic system for expansion coil-inner-hole with 4 palms Link-connect expanding system Pump power=1.5KW Load capacity=3 Ton,Coil Inner - diameter =451-530 mm Coil outer-diameter=Max. 1500 mm Coiler Width=Max. 600 mm |

| Manual Pre-shearing device | Smart cut control, to cut off the end of the final piece of sheet only |

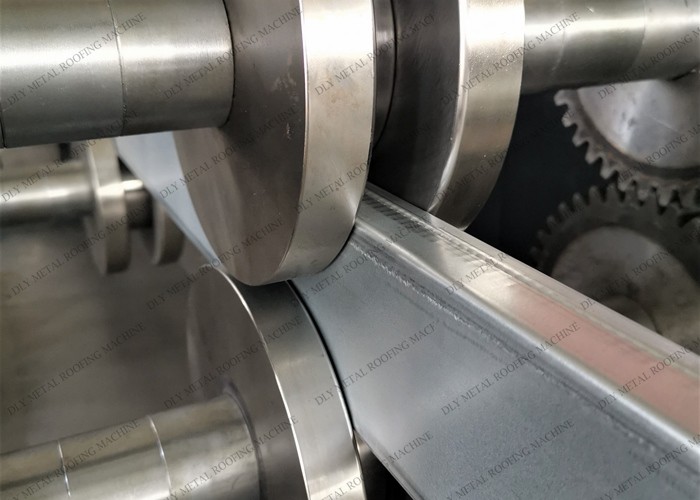

| Cold Rolling Mills | Feeding section with guide Gear/Sprocket driving 16-step to form Rollers manufactured from 40Cr, CNC lathes, hard Chrome Coated. Shaft Diameter: Φ75mm, Precision Machined Main Motor: 4.0KW, Frequency speed control Forming speed approx. 12m/min Protection Mesh Cover (full mesh type) Above Roll-former To Avoid Hands go Inside, slip type |

| Hydraulic Cutting Device | Stop to cut, Post cut, slug breaker Pump motor =3.0KW |

| PLC Control System | Control the quantity & cutting length automatically. Combined with: PLC, Touch Screen, Inverter (Siemens), Encoder (Omron), etc Cut-to-length tolerance≤±2 mm Control Voltage: 24V |

| Product Rack | un-powered, 4 meters length |

3. Features of Pipe Profiling Machine

Passive uncoil— Feeding—Roll forming—Cut to length—Output

table—Elbow with pipe

This equipment is used for producing door frame, window rail support, storage rack, drawer slider, light steel keel, pipe,highway guardrail and so on. The whole production line consists of a material-putting rack, forming main machine and hydraulic set-length punching-cutting machine. Its shearing involves no waste,not producing shearing waste and saving the cost of material,with high production efficiency.

4. Detail Photos of Pipe Profiling Machine

The processing and detail of each part, the assembly of the machine, all determine the quality of a machine. We strive to do a good job in every link, every process, so that the machine in the process of use can be more stable, longer service life.