DLY Metal Roofing Machine |

|

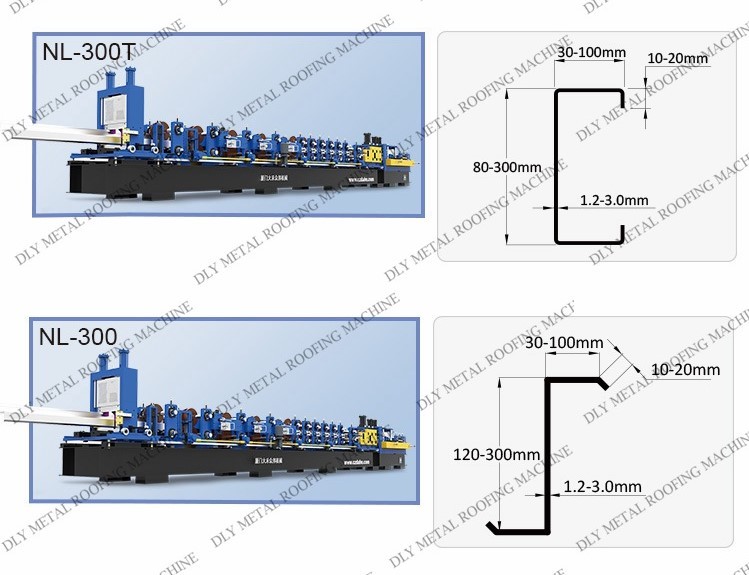

C80 C Purlin Roll Forming Machine Z120-300 C Purlin Roll Forming Machine

1. Description of C U Z Purlin Roll Forming Machine

The C&Z purlin forming machines are specifically used to

manufacture multi-size C and Z purlin channels.

The Roll tools are carved in highly precise CNC machines which

gives it better quality and longer service life as we say “Quality

& Service are the main ingredients of our Machines”

The Machine’s parts are all made with precision and experienced

personals, with optimum quality roll tools so you never have to

worry about the machine quality.

2. Specifications of C U Z Purlin Roll Forming Machine

| Type | Roll former for C/Z PURLINE |

| Thickness | 1.5mm-3.5mm |

| Frame Design | Wall-plate-frame-design /New-stand-frame-design |

| Roll Stages | 20 stages |

| Material Of Forming Roller | GCr15, CNC lathes, Heat Treatment, Hard Chrome Coated |

| Shafts Diameter | Φ75/95 mm |

| Main Motor Power | 30KW |

| Max. Line Speed of Roll Former | 30m/min (Higher speed is available, depends on the specification required by the buyer) |

| Hydraulic Group Power | 15 KW |

| Material of Cutting Blade | Cr12, hear treatment |

| Electric Standard | 380V /50Hz/3PH or as per customer's requirements |

| Machine Dimensions | 10000mm×1650mm×1200mm |

| Major Color of Machine Painted | RAL 5015 (Blue) or as per customer's requirements |

3. Profiles of C U Z Purlin Roll Forming Machine

4. Advantages of C U Z Purlin Roll Forming Machine

5. Detail photos of C U Z Purlin Roll Forming Machine