DLY Metal Roofing Machine |

|

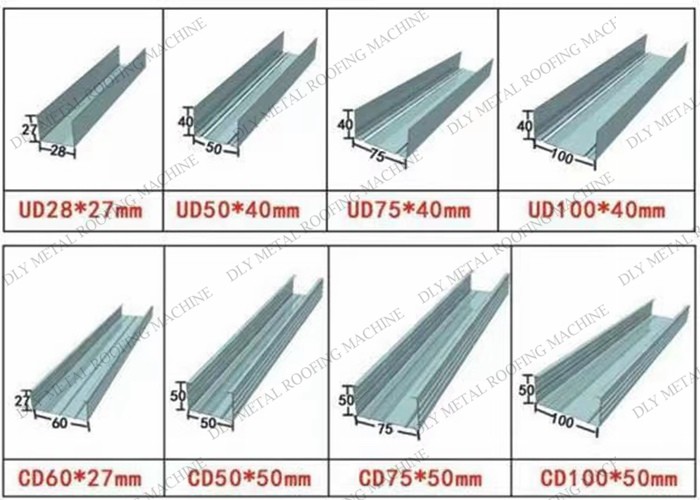

3500kg Omega Shape Forming Machine 3P U Channel Roll Forming Machine

1. Specification of Keel Roll Forming Machine

roll forming light steel keel rollformer machine parameters | |

Suitable to process | Color alu-zinc steel strips |

Roller | 12Rows plus leveling device |

Dimensions | 5.4*1*1.5m |

Motor Power | 3Kw |

Pump Station Motor | 3Kw.Lichao Brand |

Thickness of the plate | 0.3-0.8mm |

Productivity | 10-15m/min |

Material of the cutting blade | Cr12,Quenched treatment 58℃-60℃ |

Diameter of the roller | Φ50mm |

Weight | About 2600kgs |

Main structure of the machine | Square steel frame |

Processing precision | Within 1.0mm |

Side panel of machine | 16mm |

Chain Wheel and Cycle Chain | 1 Inch |

Voltage | 380V 50Hz 3phases or as customer's need |

Control system | PLC control (Delta) |

Frequency system | Delta |

Drive mode | Gear driver |

Touch screen | Delta |

Rolling materials | 45# forging steel with chromium plate |

Length Tolerance | ±2mm |

2. description of Keel Roll Forming Machine

Light steel keel molding machine is used to plaster board, gypsum board and other decorative finishes lightweight board made of non-load-bearing walls and roof of the building style decoration, a variety of decorative building roof shape, inside and outside the building wall and ceiling scaffolding base material. Used in hotels, terminals, bus terminal, railway stations, theaters, shopping malls, factories, office buildings, old building renovation, interior decoration settings, roof and other places.

3. Advantage of Keel Roll Forming Machine

4. details photos of Keel Roll Forming Machine