Jiangyin Dingbo Technology CO., Ltd. |

|

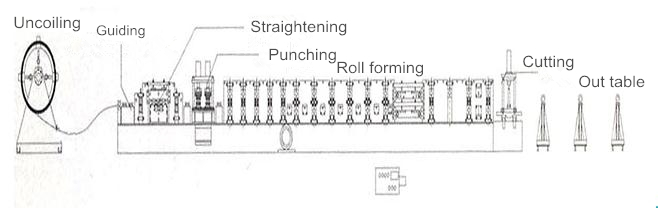

highway guardrail building material roll forming machine

Product Descriptions

The highway guardrail roll forming machine can be designed as two or three wave profiles in one machine, you just need to add some stations at the end of the machine. This guardrail roll forming machine composed with 5 ton manual decoile, feeding guide device, straighten and leveling device, front hydraulic punching device, roll forming machine, hydraulic cutting and auto stacker or manual stacker for finished products.

Working Flow

Decoiler -- Leveing -- Punching -- Roll-forming -- shearing --

Output table

Product Parameters

Main motor power | 7.5KW |

Hydraulic station power | 4KW |

Roller station | 16 |

Diameter of principal axis | 70MM |

Material of roller | 45#steel hard chrome plating |

Processing speed | 8-10m/min |

Thickness | 0.3-1mm |

Installation dimension about(L*W*H) | 9*1.5*0.8M |

Wave height | 35mm |

Wave length | 125mm |

Cover width | 750mm |

Material of blade | Cr12 |

Main models

| Name | Quantity( set) |

| Decoiler | 1 |

| Level device | 1 |

| Main forming machine | 1 |

| Hydraulic punching | 1 |

| Hydraulic cutting machine | 1 |

| PLC Control Panel | 1 |

| Run out table | 2 |

Machine pic

Our service

Designing:

After order confirmation, we start to design the machine, such as

the basement, structure, rollers, shafts, power, cutting device,

programs and so on.

Making:

The main parts, like rollers and shafts are produced by ourselves.

We have several high-precision CNC lathe and other kinds of new

machine tools, so that the quality and precision can be controlled.

Assembling:

The machines are assembled by technicians with years of experience,

which can help workers improve the production efficiency and

machine’s quality.

Testing:

Raw material of different specifications are prepared for testing.

And during test, long enough material is used. Because if the

material is not long enough, some defects can not be exposed.

Delivery:

Machine will be fixed inside container by steel wire, in order to

make sure it won’t move during transportation and avoid any kinds

of damage of machine and container.

Main features

1. We can make and design all kinds of roll forming machine

according to customer's requests.

2. This is a very perfect and durable equipment. We have more than

20 years experiences.

3. This kind of machine has the best quality and the best price. It

has accurate measurement and easy operating.

4. We can design and manufacture the special type machine according

to the customers' requirement and we could provide technical

guiding, production, installation, debugging and maintenance

service to all customers.

5. Our product has been exported to many regions and won high

reputation because of the high quality and reasonable price.