Jiangyin Dingbo Technology CO., Ltd. |

|

Steel strip slitting line

Products Description

The coil steel slitting line is used for the metal plate decoiling, slitting and winding into several volumes needed width coil plate. Suitable for processing of cold rolled and hot rolled carbon steel, silicon steel, tinplate, stainless steel and the surface of all kinds of metal plate after plating.

technological process

Material loading cart → Double loading uncoiling → Leading head, shoveling head, pitch roller feeding, end shearing machine → Deviation-correcting device → Slitting machine → Scrap institution → Loop → Pre-segregation, tension machine→ Coiler → Material unloading cart → Hydraulic control→ Electric control system

Product Paramenters

| Items | Main specification |

| Material | PPGI, GI, Aluminum, Carbon steel, Hot Rolled, Cold Rolled, Stainless steel |

| Thickness | 0.5-3mm |

| Width | 500-1600mm |

| Inner diameter | 508mm, 610mm |

| Max outer diameter | 1600mm |

| Max weight | 10-25T |

| Slitting speed | 0-100m/min |

| Max slit quantity | 8 pcs (3mm) 25 pcs(0.5mm) |

| Power | 380V/50Hz/3PH(Customized) |

| Whole line Dimension | 24m(L)X8m(W) |

| Operator needed | 1 mechanical engineer ,2 common workers |

| Line direction | From right to left (Face to machine) |

Main Items

| 1 | Loading coil car |

| 2 | Decoiler |

| 3 | Straightener device(optional) |

| 4 | Head Shear /Pinch roll/(optional)/Film Device(optional) |

| 5 | Bridge/Loop pit |

| 6 | Side guide |

| 7 | Slitter |

| 8 | Side Guide & scrap winder |

| 9 | Bridge /Loop pit |

| 10 | Separator &Tension station |

| 11 | Recoiler and Support Arm |

| 12 | Unloading coil car |

| 13 | Hydraulic system |

| 14 | Pneumatic System |

| 15 | Electronic Controller( PLC Control Table) |

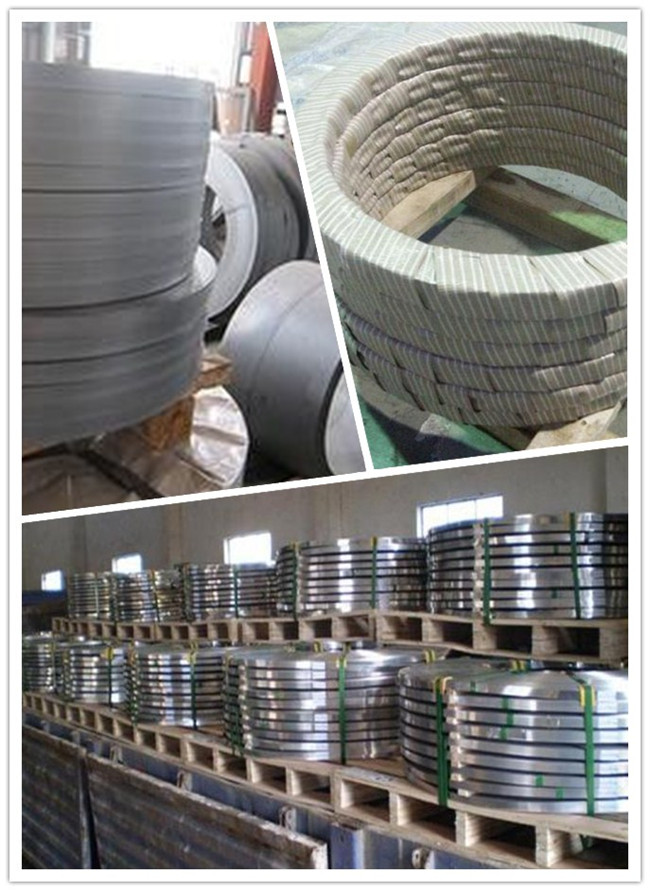

Application pic

Our service

Designing:

After order confirmation, we start to design the machine, such as

the basement, structure, rollers, shafts, power, cutting device,

programs and so on.

Making:

The main parts, like rollers and shafts are produced by ourselves.

We have several high-precision CNC lathe and other kinds of new

machine tools, so that the quality and precision can be controlled.

Assembling:

The machines are assembled by technicians with years of experience,

which can help workers improve the production efficiency and

machine’s quality.

Testing:

Raw material of different specifications are prepared for testing.

And during test, long enough material is used. Because if the

material is not long enough, some defects can not be exposed.

Delivery:

Machine will be fixed inside container by steel wire, in order to

make sure it won’t move during transportation and avoid any kinds

of damage of machine and container.

Main features

1. We can make and design all kinds of roll forming machine

according to customer's requests.

2. This is a very perfect and durable equipment. We have more than

20 years experiences.

3. This kind of machine has the best quality and the best price. It

has accurate measurement and easy operating.

4. We can design and manufacture the special type machine according

to the customers' requirement and we could provide technical

guiding, production, installation, debugging and maintenance

service to all customers.

5. Our product has been exported to many regions and won high

reputation because of the high quality and reasonable price.