Jiangyin Dingbo Technology CO., Ltd. |

|

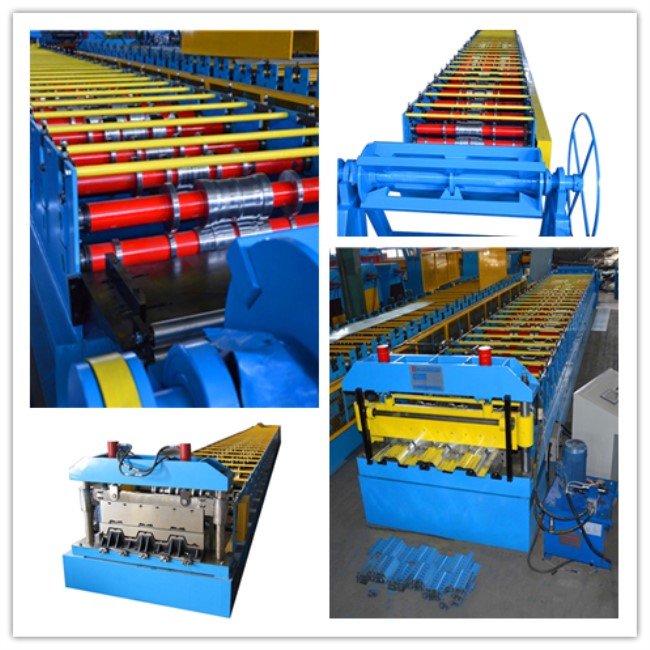

Metal Deck Sheet Roll Forming Machine

Product Descriptions

The floor deck roll forming machine is used for floor floor panels with high strength and good adhesion. In the high-rise building, the steel formwork can be omitted and the floor load can be reduced. Under the premise of achieving the same bearing capacity, the amount of engineering steel can be reduced, thereby saving input costs.

1. The structure is simple and the appearance is beautiful. Because the whole machine adopts the steel structure and the whole processing after welding, the structure is simple and reasonable, the bearing capacity is strong, and the operation is stable and reliable. Large equipment customized for thick plates.

2.Set other important components and components to use domestic or imported famous brand accessories to ensure the performance of the equipment.

3. Equipment installation and debugging is convenient, easy to operate.

4. Low noise, no pollution, low consumption.

Version to design

Product Parameters

| Type | Metal Deck Sheet Roll Forming Machine |

| Thickness | 0.8mm-1.6mm |

| Feeding Width | 1220mm |

| Frame Design | Wall-plate-frame-design /New-stand-frame-design |

| Roll Stages | 18 stages |

| Material Of Forming Roller | 45# steel, CNC lathes, Hard Chrome Coated |

| Shafts Diameter | Φ95mm |

| Main Motor Power | 15KW×2 with reducer |

| Max. Line Speed of Roll Former | 15m/min (Higher speed is available, depends on the specification required by the buyer) |

| Hydraulic Group Power | 5.5KW |

| Material of Cutting Blade | Cr12, hear treatment |

| Electric Standard | 380V /50Hz/3PH or as per customer's requirements |

| Machine Dimensions | part A+B:11200mm*2080mm*1050mm Part C: 7000mm*2050mm*1700 mm |

| Major Color of Machine Painted | RAL 5015 (Blue) or as per customer’s requirements |

Main Components

| Decoiler / Uncoiler | 1 Unit |

| Feeding Guide | 1 Unit |

| Roll Forming Machine | 1 Unit |

| Hydraulic Cutting Device | 1 Unit |

| Hydraulic Station | 1 Unit |

| PLC Computer Control Board | 1 Unit |

| Runout Tables | 2 Units |

Machine pic

Application

Our service

Designing:

After order confirmation, we start to design the machine, such as the basement, structure, rollers, shafts, power, cutting device, programs and so on.

Making:

The main parts, like rollers and shafts are produced by ourselves. We have several high-precision CNC lathe and other kinds of new machine tools, so that the quality and precision can be controlled.

Assembling:

The machines are assembled by technicians with years of experience, which can help workers improve the production efficiency and machine’s quality.

Testing:

Raw material of different specifications are prepared for testing. And during test, long enough material is used. Because if the material is not long enough, some defects can not be exposed.

Delivery:

Machine will be fixed inside container by steel wire, in order to make sure it won’t move during transportation and avoid any kinds of damage of machine and container.

Main features

1. We can make and design all kinds of roll forming machine according to customer's requests.

2. This is a very perfect and durable equipment. We have more than

20 years experiences.

3. This kind of machine has the best quality and the best price. It

has accurate measurement and easy operating.

4. We can design and manufacture the special type machine according

to the customers' requirement and we could provide technical

guiding, production, installation, debugging and maintenance

service to all customers.

5. Our product has been exported to many regions and won high

reputation because of the high quality and reasonable price.