Jiangyin Dingbo Technology CO., Ltd. |

|

Heavy Duty Highway Guardrail Roll Forming Machine with Gearbox Transmission

Main components

This highway guardrail roll forming machine can be designed as two or three wave profiles in one machine, you just need to add some stations at the end of the machine. The guardrail roll forming machine composed with 5 ton manual decoiler, feeding guide device, straighten and leveling device, front hydraulic punching device, roll forming machine, hydraulic cutting and auto stacker or manual stacker for finished products.

Working flow

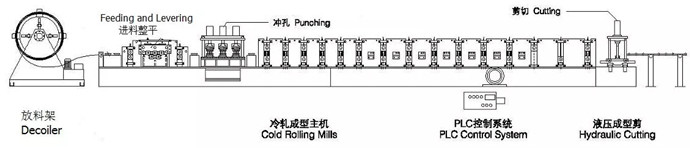

Uncoiling — Feeding & Leveling — Punching — Roll forming — Cutting — Output table

Machine pic

| 1 | Material Width | 500-1000mm |

| 2 | Effective Width | 480-680mm |

| 3 | Thickness of Coil | 2.0-4.0mm |

| 4 | Application | Highway Guardrail |

| 5 | Estimated Dimension | 15000mmX1800mmX1200mm |

| 6 | Total Weight | 20 Tons |

| 7 | Main Power | 37 KW |

| 8 | Decoiler | Manual or Hydraulic Decoiler |

| 9 | Inner Diameter | 508mm |

| 10 | Outer Diameter | 1200mm |

| 11 | Loading Weight | 5T |

| 12 | Forming Speed | 10m/min |

| 13 | Forming Station | 12-15 |

| 14 | Bracket | Welded with 36 # I-steel |

| 15 | Material of Shaft | High Grade 45# Steel with 1st Rough Finished and then 2th Refined Finished |

| 16 | Diameter of the Roll | 100mm |

| 17 | Material of Roller | High Quality CGr15 Quenched HRC58-62 ° |

| 18 | Processing Technology | Rough Processing ---Refined Processing--Hard Chromium Plating |

| 19 | Material of Rack | Complete Welded Structure of A3 Steel Plate 20 mm Thickness |

| 20 | Transmission | Chain or Gear Box |

| 21 | Material of cutting blade | Cr12 with Quenched Treatment 60-62 ° |

| 22 | Cutting system | Hydraulic Cutting |

| 23 | Voltage | 380V/50HZ/3 Phase or as Customer Require |

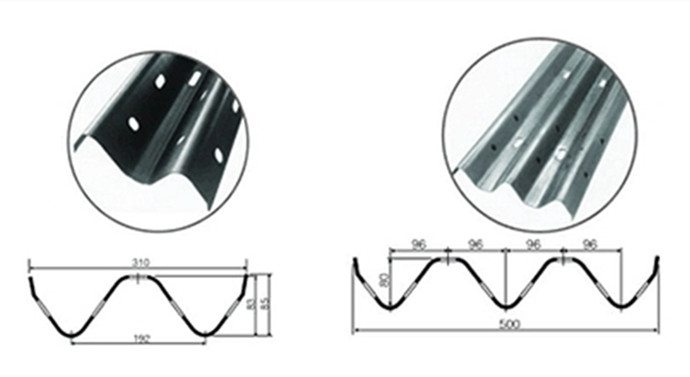

Profile drawing

Production process

Why choose us

1. We can make and design all kinds of roll forming machine

according to customer’s requests.

2. This is a very perfect and durable equipment. We have more than

20 years experiences.

3. This kind of machine has the best quality and the best price. It

has accurate measurement and easy operating.

4. We can design and manufacture the special type machine according

to the customers’ requirement and we could provide technical

guiding, production, installation, debugging and maintenance

service to all customers.

5. Our product has been exported to many regions and won high

reputation because of the high quality and reasonable price.

FAQ

1. Does one machine can only produce one size?

Not exactly, it depends on which profile the customer want to

produce.

2. Do you have after-sales technical support?

Yes,we are happy to give advice and also have skilled technicians

available to maintain the machine overseas to customers’ workshop

if needed.

3. You are trading company or factory?

We are Manufacturer, and we export our machine by ourselves.

4. How long the machine could be made?

Normally speaking, high precision roll forming machine could be

made out with 40 working days.If you need machines in hurry, we can

make it for you less than a month.

5. Do you provide customized?

Sure, we can design the machine according to the requirement and

profile drawing you provide. Our engineers can offer the best

professional solution to our worldwide clients.

6. May we visit your factory?

Sure,Warmly welcome to our factory at any time.

7. How to visit your factory?

By high speed train from Shanghai to East Wuxi (Wuxi Dong station),

half an hour.

8. What's the warranty period?

12 months warranty period, starting from the date of the successful

installation and commissioning of the equipments at the Buyer’s

Installation site.

9. Can we arrange shipment?

Yes, sure, we can arrange shipment for our customers and provide

door-to-door service.

Best Regards

Andy Yang

Director

Mobile/Wechat/Skype:0086 139 2126 2246