Jiangyin Dingbo Technology CO., Ltd. |

|

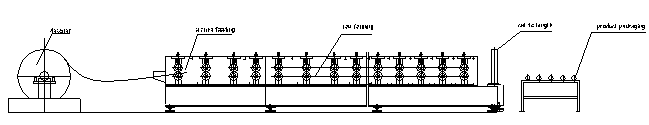

Durable Shutter Roll Forming Machine 13 stations Roller Shutter Door Slats Forming Machine

Main features

Rolling shutter door roll forming machine equipment with high efficiency, low energy consumption, and reduce environmental pollution, the steel structure also has a considerable breakthrough, bring more benefits to the market, Our company has more than ten years of production experience in the production of roller shutter door equipment, and the door slat rolling machine is mainly divided into two types: basic and comprehensive.

Working flow

Decoiling----Sheet Feeding ----Guilding----Roll forming-----Punching----Cutting----Out able

Technical parameters

| 5Tons Manual Deocoiler | Coil Inner-diameter=510±30mm. Coil Outer-diameter Max. 1300mm; | ||

| Taper wedge expanding system | |||

| Load Capacity: Max. 1.5 Tons; Coil Width Max. 1250mm; | |||

| Shutter Door Machine | Gear/Sprocket driving; 13 stations roll forming | ||

| Rollers manufactured from 45# steel | |||

| Shafts Diameter=65mm, Precision Machined, fine Polished | |||

| Main motor =4KW, Frequency speed control | |||

| Max Line speed of roll Former: Approx. 10-15m/min | |||

| Hydraulic Cutting Device | Stop to cut, Post cut | ||

| Cutting tool material: Cr12, Heat treatment | |||

| Hydraulic unit, Pump motor =3KW | |||

| PLC Control System | Control the quantity & cutting length automatically | ||

| Combined with: PLC (Delta), Touch Screen (Delta), Encoder (Omron), etc | |||

| Cut-to-length tolerance≤±2mm | |||

| 24V Control voltage | |||

| Controller with forward/backward/emergency stop buttons | |||

| Product Rack | Un-powered, 3 units | ||

Machine components

| NO | Name | Unit | Qty |

| 1 | Man-made decoiler | set | 1 |

| 2 | Main machine for roll forming | set | 1 |

| 3 | Control system | set | 1 |

| 4 | Hydraulic system | set | 1 |

Our certificate

Advanced machinery, well trained workers.

More than 20 years experience in roll forming machine industry.

Unique designed, good Germany quality, competitive China price.

Full process of roll forming machine solution.

Shipment arrangement available.

After-sales services for overseas installation and commissioning

Jiangyin Dingbo Technology Co., Ltd. is professional manufacturer and exporter specializing in designing, manufacturing, technology developing, sales and services in building materials machinery whcih mainly include all kinds of roll forming machine, tube making machine, slitting line and cut to length line,and discontinuous PU sandwich panel production line and embossing machine.

The main products of our factory is color steel roofing and wall roll forming machine, pre-painted steel forming machine, floor deck forming machine, automatical C/Z Purlin forming machine, Guardrail forming machine, Racking roll forming machine, cable tray roll forming machine, Glazed Tile forming machine, DownPipe forming machine, Roller shutter door machine,tube mill, steell and aluminum embossing machine,steel slitting and cut to length line, PU sandwich panel line and so on.

The products are widely used in such as building structure, steel structure warehouse, factory buildings, supermarket, Nursing homes, villas and other construction projects, Our factory can meet the construction enterprises, automobile industry, Iron and steel production enterprises' growing demands.

Dingbo Technology is located in Wuxi city, Jiangsu province which is very close to Shanghai, It's about half an hour's journey. We enojoy the convenient transportation and advantageous location which supply good business opportunities for the buyers home and abroad.

1. Does one machine can only produce one size?

Not exactly, it depends on which profile the customer want to produce.

2.Do you have after-sales technical support?

Yes,we are happy to give advice and also have skilled technicians

available to maintain the machine overseas to customers’ workshop if needed.

3. You are trading company or factory?

We are Manufacturer, and we export our machine by ourselves.

4.How long the machine could be made?

Normally speaking, high precision roll forming machine could be

made out with 40 working days.If you need machines in hurry, we can

make it for you less than a month.

5. Do you provide customized?

Sure, we can design the machine according to the requirement and profile drawing you provide. Our engineers can offer the best professional solution to our

worldwide clients.

6. May we visit your factory?

Sure,Warmly welcome to our factory at any time.

7.How to visit your factory?

By high speed train from Shanghai to East Wuxi (Wuxi Dong station), half an hour.

8.What's the warranty period?

12 months warranty period, starting from the date of the successful

installation and commissioning of the equipments at the Buyer’s

Installation site.

9.Can we arrange shipment?

Yes, sure, we can arrange shipment for our customers and provide door-to-door service.

Best Regards

Andy Yang

Director

Mobile/Wechat/Skype:0086 139 2126 2246