Jiangyin Dingbo Technology CO., Ltd. |

|

Chain Or Gear Box Driven System Light steel Roll Forming Machine For Steel Construction

Product Features And Descriptions

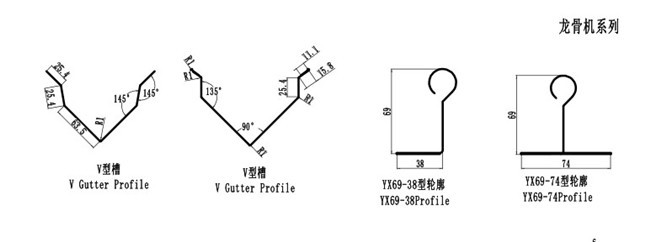

Light steel keel moulding machine produces light steel keel to have condole top keel and partition keel according to use, have V type, C type, T type, L type, U type keel according to sectional form.

The marking order of light steel keel produced by light steel keel is: product name, code name, width of section shape, height, steel plate thickness and standard number.

Working flow

Uncoiler--Feeding--Punching--Leveling--Roll-forming--Hydraulic-cutting--Output

table

Product Parameters

| Item | Parameter detail | ||||||||

| Processing Material | GI and PPGI | ||||||||

| Material thickness | 0.4-0.8mm | ||||||||

| Machine frame | 360#H steel, Adopt diagonal line welding, leveling instrument measurement to make sure the final frame is high-precision | ||||||||

| Machine siding panel |

| ||||||||

| Forming stations | 10-22 stations(according to the profiles) | ||||||||

| Machine rollers | high grade Cr12 steel,plated hard chroming with thickness 0.05mm chroming | ||||||||

| Machine Shaft | φ60-70mm high garde No.45 steel after treatment, | ||||||||

| Machine spacers | CNC lathing in high-precision | ||||||||

| Machine bearings | China Haerbin bearing or SKF international bearing(option) | ||||||||

| Driving system | Gear or gear box(option) | ||||||||

| Machine power | 3kw-5.5kw(according to the profiles) | ||||||||

| Machine working speed | 8-12m/min or 10-30m/min(option) | ||||||||

| Machine adjust type | After machine installation, we will test it ourselves, compare with the profile drawing, the difference is controlled in 0.5mm

|

Machine components

Decoiler,Punching-machine,Main forming machine,PLC control system,Hydraulic pump station,Post cutting,Electric motor,Output table

Picture

After sale services

1.Engineer will give free training lessons to labors in buyer’s

factory.

2.The Buyer will buy the round-trip air ticket for Engineer if visa

application is approved. The buyer is also responsible to bear

expenses generated, e.g. visa formalities, meals, accommodation and

allowance of USD80 for engineer per day.

3.During this guarantee period, we will provide spare parts without

any charge in case of quality discrepancy caused by us. If the

malfunctions are caused by your incorrect operations, we will

provide the buyer spare parts at cost price.

4.We will charge the buyer cost price of spare parts beyond 2 years

and provide long-term technical guide.

FAQ

1. Does one machine can only produce one size?

Not exactly, it depends on which profile the customer want to

produce.

2.Do you have after-sales technical support?

Yes,we are happy to give advice and also have skilled technicians

available to maintain the machine overseas to customers’ workshop

if needed.

3. You are trading company or factory?

We are Manufacturer, and we export our machine by ourselves.

4.How long the machine could be made?

Normally speaking, high precision roll forming machine could be

made out with 40 working days.If you need machines in hurry, we can

make it for you less than a month.

5. Do you provide customized?

Sure, we can design the machine according to the requirement and

profile drawing you provide. Our engineers can offer the best

professional solution to our worldwide clients.

6. May we visit your factory?

Sure,Warmly welcome to our factory at any time.

7.How to visit your factory?

By high speed train from Shanghai to East Wuxi (Wuxi Dong station),

half an hour.

8.What's the warranty period?

12 months warranty period, starting from the date of the successful

installation and commissioning of the equipments at the Buyer’s

Installation site.

9.Can we arrange shipment?

Yes, sure, we can arrange shipment for our customers and provide

door-to-door service.

Best Regards

Andy Yang

Director

Mobile/Wechat/Skype:0086 139 2126 2246