Jiangyin Dingbo Technology CO., Ltd. |

|

High Speed W Beam Highway Guardrail Forming Machine / Rolling Forming Machine

Brief introduction of guardrail roll forming machine

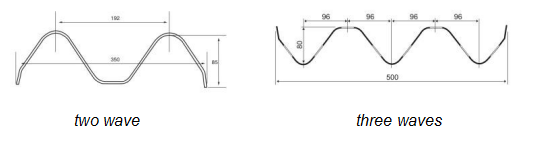

This guardrail roll forming machine is use for producing highway guardrail panel, which divided into 2 waves and 3 waves guardrail panels, and widely used in high speed way all around the world. It is comprised of mechanic decoiler, guiding and feeding equipment, leveling device, pre-punching hydraulic device, roll forming unit, post hydraulic mould cutting device, hydraulic station, PLC control system and unloading rack.

The drawings of guardrail panels

Main technical parameters of guardrail roll forming machine

1). Main motor power:18.5kw

2). Hydraulic station power:7.5kw

3). Sprocket:P-25.4

4). Forming station:21

5). Material of roll:45#steel hard chrome plate

6). Length of production line:11m

7). nstallation dimension about(L*W*H):11*1.5*1.4m

8). Diameter of principal axis:100mm

9). Hydraulic oil pump:CB-E310

10). Material of blade:Cr12

11). Thickness: 1-3mm

12). Length of tolerance:±2mm

13). Processing speed:10-15m/min

14). Total weight: 4.2T

15). Equipment parts: decoiler, roll forming machine, forming press

system, hydraulic cutter, hydraulic system, computer

control,counter.

Pictures of guardrail roll forming machine

After sale services