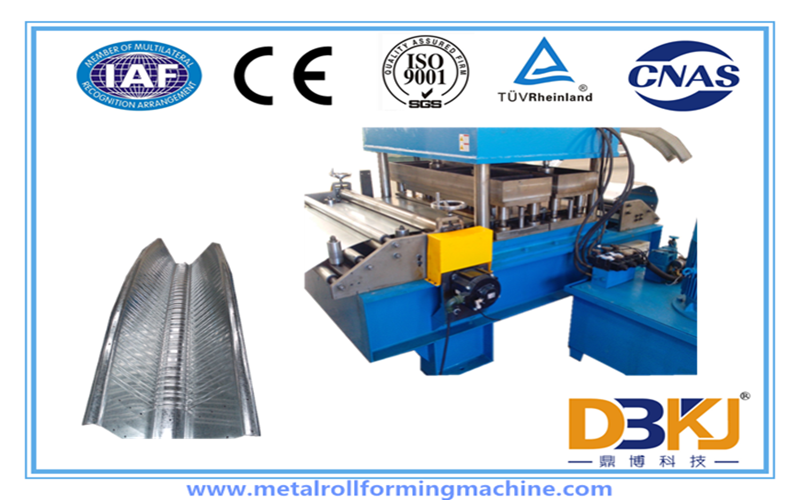

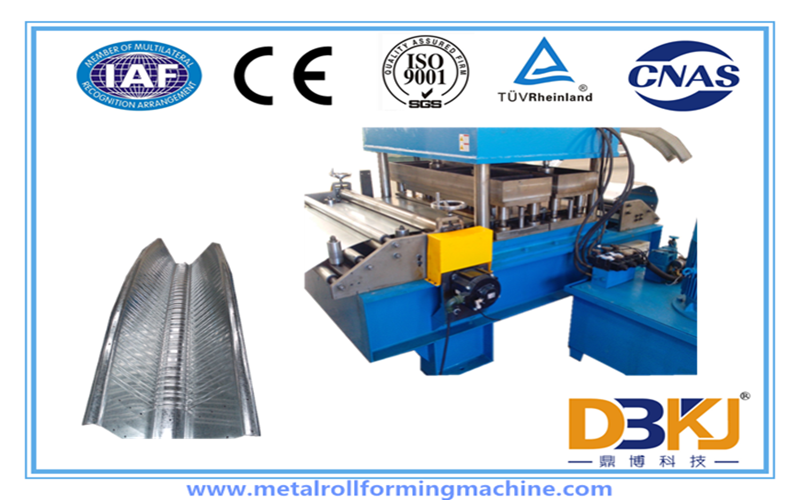

Automatic K span roll forming machine for sale

Brief introduction of K span roll forming machine

- All the components of machine are from brand-famous enterprise so

that they ensure the machine normal function very effectively.

- We adopt the automatic length-fixed forming and cutting to

guarantee the length to be precise and the finished product clear

without deforming .

- It is very easy to install the equipment and suitable for producing

in the factory.

- The machine has features of low noise and high efficiency.

- It has the ability of strong loading and stable operation when

running the machine.

- The structure is simple and the appearance of the machine is

beautiful because we adopt the shape-steel structure and process as

a whole after welding

9R3{S3G51BM05VSB{8_V.png)

9R3{S3G51BM05VSB{8_V.png)

9R3{S3G51BM05VSB{8_V.png) Main technical parameters

Main technical parameters

| Item | Description |

| Coil width | 914mm |

| Effective width | 610mm |

| working speed | 12m—15m/min (not contain cutting) |

| Roll station | 24stations |

| Material of roller | 45#forge steel, polished and coated with chrome |

| Material of main shaft | 45﹟forge steel |

| Diameter roller | Ф76mm |

| Total power | 18.5kw |

| Forming thickness | 0.8mm—1.2mm galvanized steel or metal 195Mpa-345Mpa |

| Transmission | By double line 1.0 inch Chains |

| Size of machine | About 9000 x 1500 x1200 (L x W x H) |

| Weight | About7 000Kgs |

| Color | Blue (it is also can changed depend on customer request) |

Working flow

Hydraulic De-coiling (5 tons + four wheel coil trolley) ---

Flatting device + Feeder by servo motor control ---- Hydraulic

punching with holes punching moulds --- Roll forming--- Cutting

---- Run-out table

Pictures

After sale services

- Engineer will give free training lessons to labors in buyer’s factory.

- The Buyer will buy the round-trip air ticket for Engineer if visa

application is approved. The buyer is also responsible to bear

expenses generated, e.g. visa formalities, meals, accommodation and

allowance of USD50 for engineer.

- During this guarantee period, we will provide spare parts without

any charge in case of quality discrepancy caused by us. If the

malfunctions are caused by your incorrect operations, we will

provide the buyer spare parts at cost price.

- We will charge the buyer cost price of spare parts beyond one year

and provide long-term technical guide.

9R3{S3G51BM05VSB{8_V.png)

9R3{S3G51BM05VSB{8_V.png)

9R3{S3G51BM05VSB{8_V.png) Main technical parameters

Main technical parameters